Catheter Braid Patterns for Medical Braiding

Maypole-style braiding machines produced by SteegerUSA are capable of creating a variety of braid patterns. Each braid pattern provides specific mechanical properties to the finished device. Available braid patterns and descriptions of the benefits are listed below.

Braid density, also known as Programmable Picks Per Inch (PPI), also plays a role in the mechanical property of the device. Steeger machines allow for up to 25 programmable segments that can be used per shaft, which can influence product performance such as steerability, pushability, torque requirements, and more.

- Full Load Catheter Braid Pattern

- Diamond Catheter Braid Pattern

- One Over One Catheter Braid Pattern

- Chase Wire Catheter Braid Pattern

- Tri-Axe Wire Catheter Braid Pattern

- Coil Catheter Braid Pattern

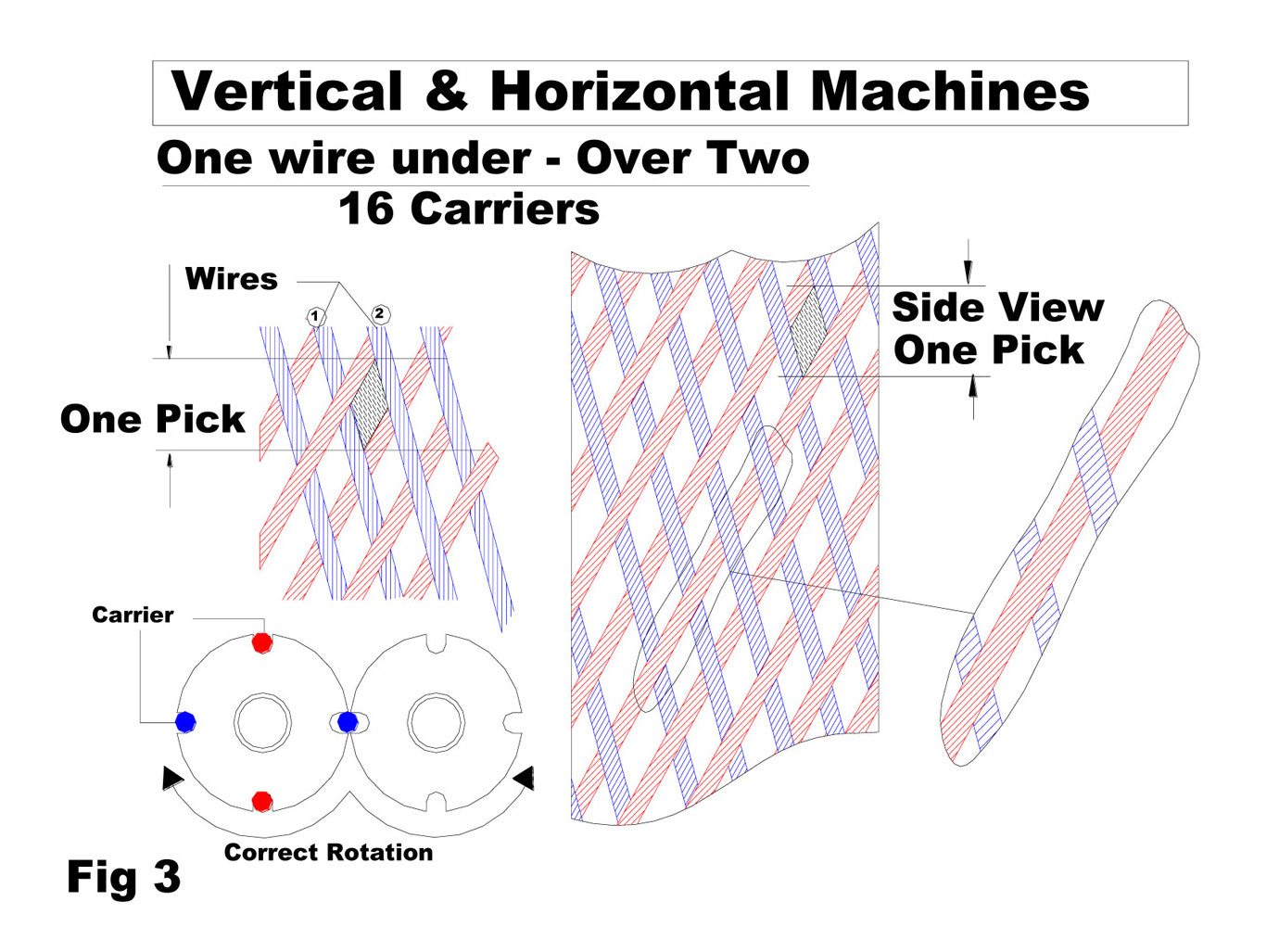

Full Load Catheter Braid Pattern

In this braided catheter pattern, one single wire under two, then over two wires. These wires rotate in opposite directions. Note, a braid machine operating in this configuration runs at 100% carrier capacity. Most proficient braid linear throughput.

If you’re looking for flexibility, pushability or to maximize energy dispersion then full load braided catheter pattern would be used with flat wire material. Full load pattern also has the benefit of braiding twice as fast as Diamond or half load due to the twice the density of the braid.

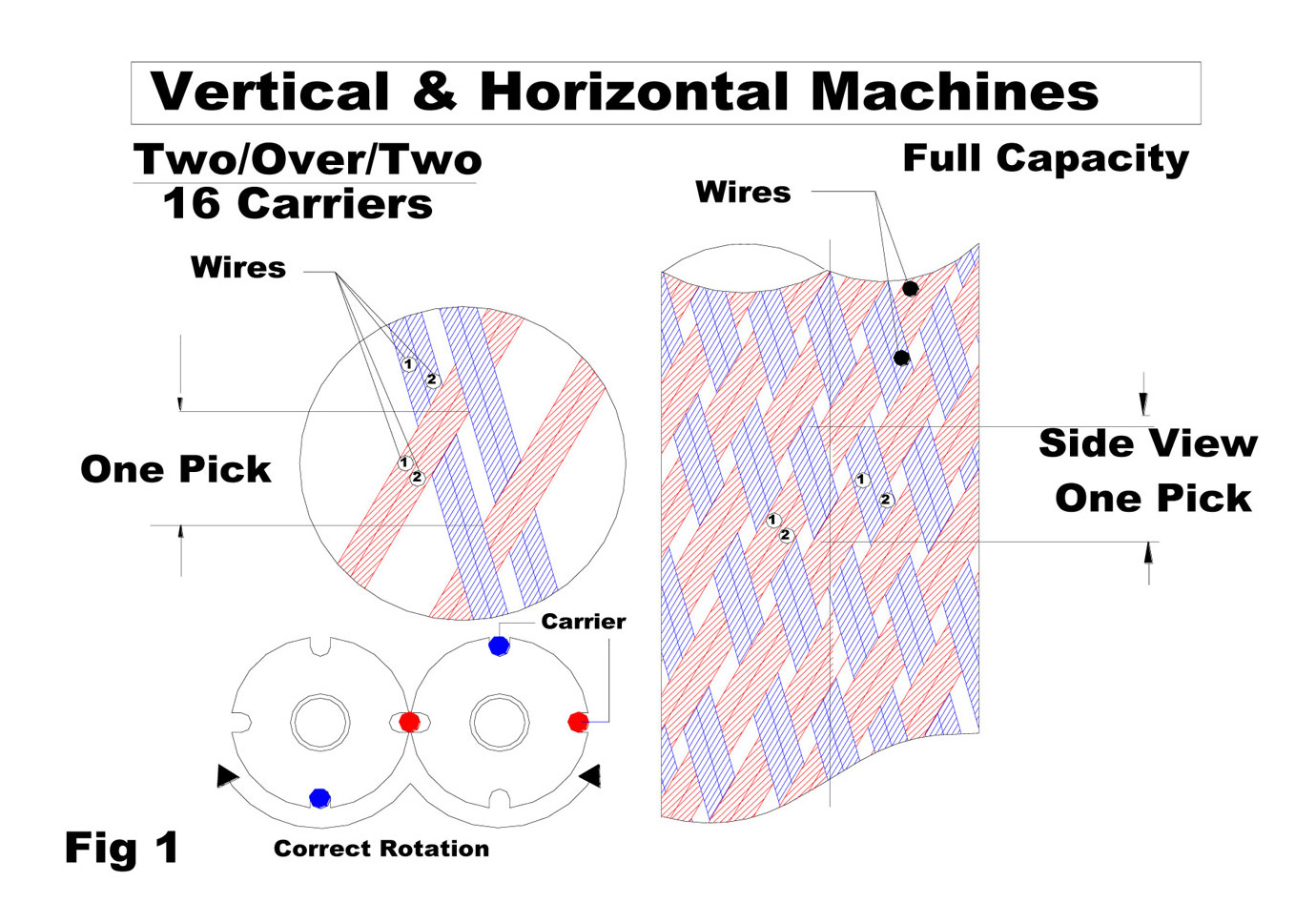

Diamond Catheter Braid Pattern

In the diamond braided catheter pattern, two wires side by side alternately pass under two wires, then over two wires. These wires rotate in opposite directions. Note, a braid machine operating in this configuration runs at full carrier capacity. Wires side by side tend to bind up against each other when taking off the core, thus increasing braid thickness.

If you’re looking for torqueability, kink resistance or full coverage you would use the Diamond full load braided catheter pattern and round wire material.

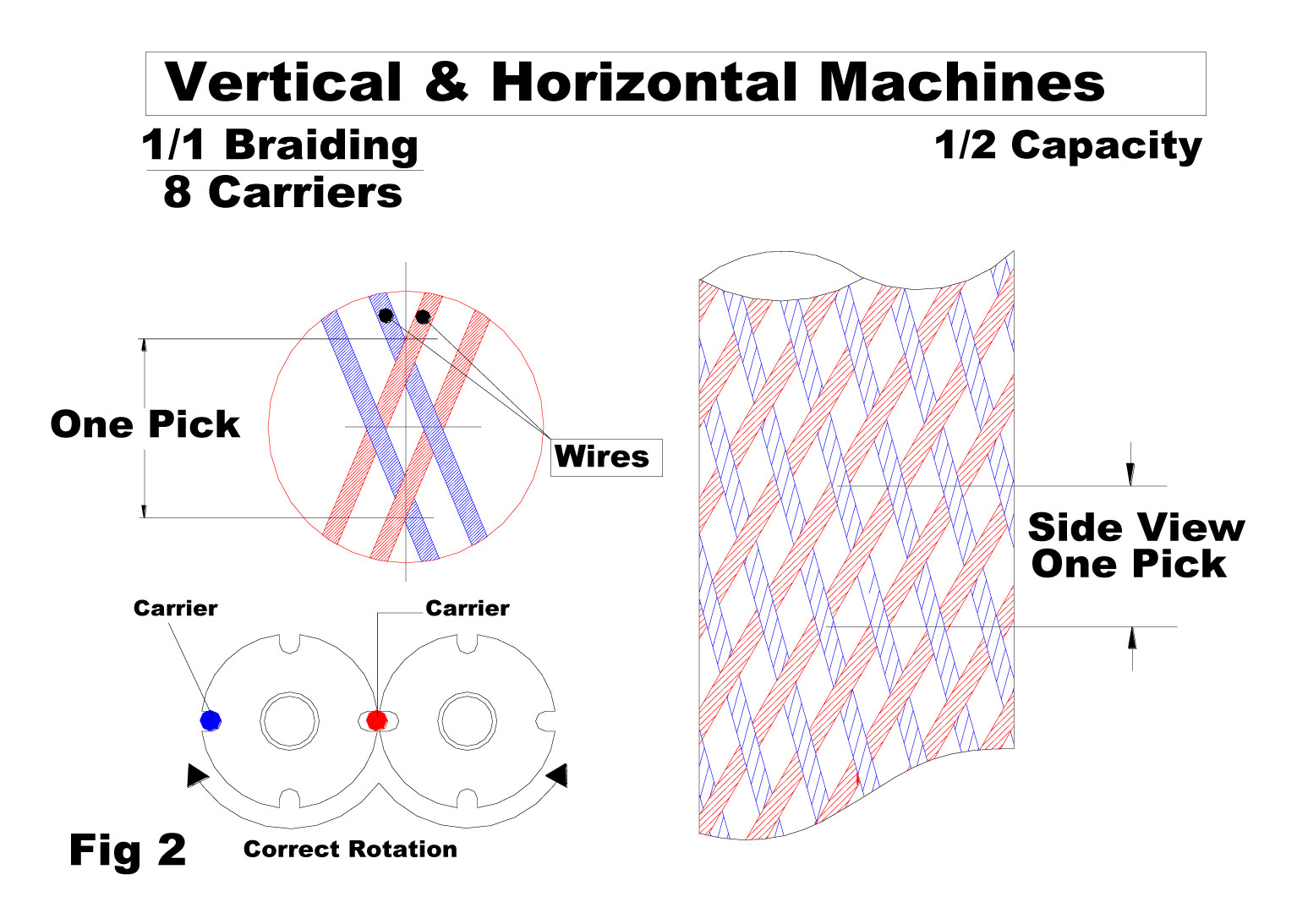

One Over One Catheter Braid Pattern

In this braided catheter pattern, one single wire alternately passes under, then over another single wire. These wires rotate in opposite directions. Note, a braid machine operating in this configuration runs at 50% capacity also known as a “half-load”. This pattern is easiest to remove from core without increasing braid thickness. Best distance between picks for extruding adhesion. Most recommended pattern to use.

This is the primary braided catheter pattern used for medical devices: 16 carrier braider in a half load, then 32 carrier in a half load, after that its function specific as to the number of carriers and load pattern. Primary material used is flat wire to help reduce overall wall thickness of the device. The braided structure of a medical device usually has at least three different PPI segments to allow it to be guided and turned.

Burst strength will be affected by load and braid angle. Diamond half load and a 45 degree braid angle offer highest integrity.

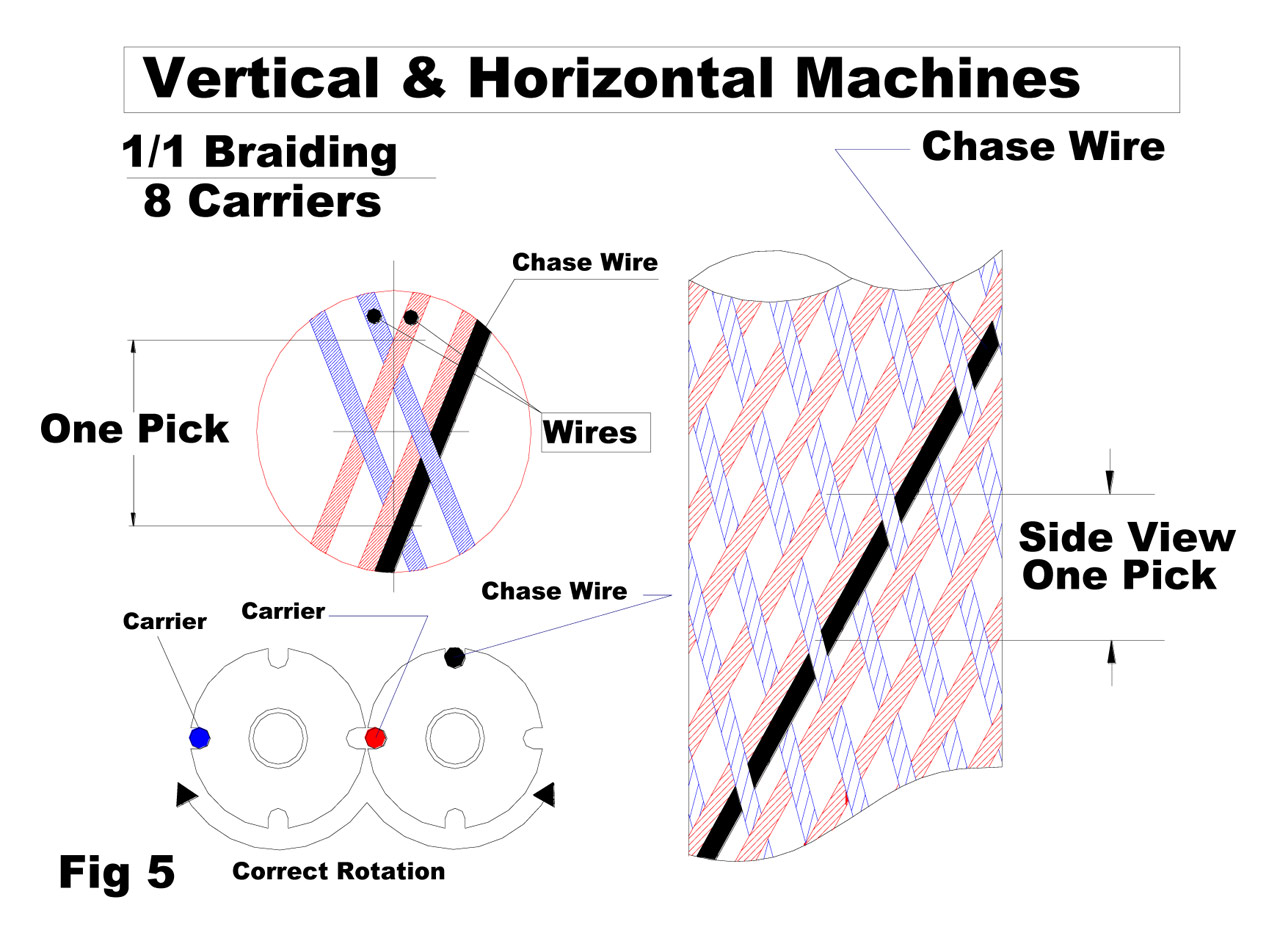

Chase Wire Catheter Braid Pattern

In this braided catheter pattern, an additional wire is braided next to a single braided wire. Up to eight wires can be chased.

Note: this configuration can only be used with a 50% capacity pattern (i.e. One Over One Pattern). Additional hardware options are required to enable this configuration.44 in these kinds of braided catheter patterns.

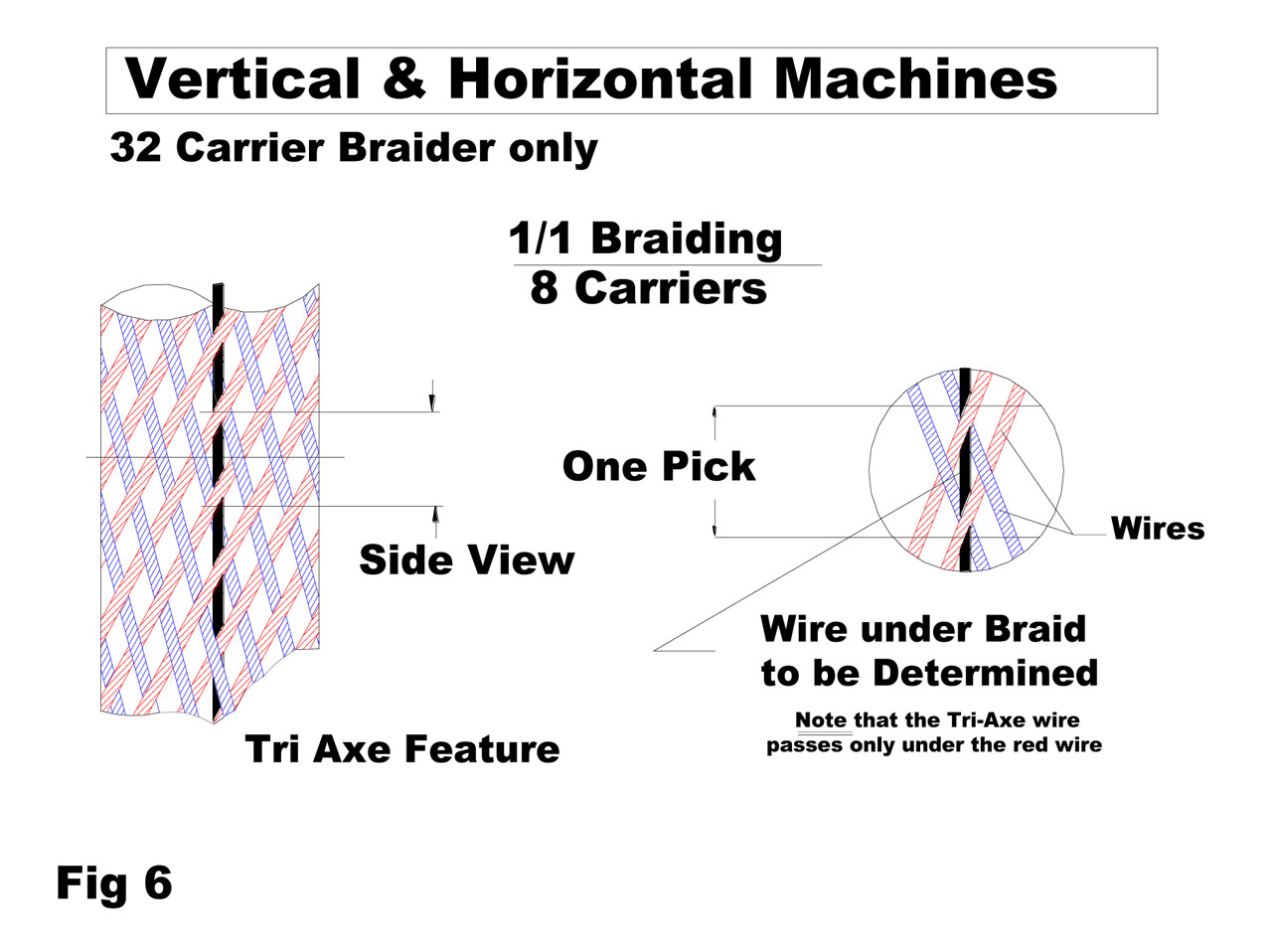

Tri-Axe Wire Catheter Braid Pattern

This braided catheter pattern can be a single or multiple wires routed straight within the braid pattern. A Tri-Axe wire is part of the braid structure that runs longitudinal along the length of the core. They are braided in and out of every other crossing or pick. Tri-Axe wires can be used up to half the capacity of a full load. A triaxial reinforces the braid, preventing it from bending, stretching or collapsing. Adding triaxials will also increase burst strength but will reduced flexibility.

A triaxial can be any material, a wire, a polymer or a fiber; depending on the application. If the triaxial is braided with a higher tension than the carrier material, then the triaxial material dominates the braid, and allows the triaxial material to move within the braid, as in the application of an articulated catheter tip.

In this braided catheter pattern, if the triaxial material is braided with an equal tension to the carrier material, then the two materials capture each other and the overall effect is to prevent the braid from expanding or collapsing, this is useful for medical reinforced silicone tubing or medical balloons, to increase burst pressure.

Note: this configuration can only be used with a 50% capacity pattern (i.e. One Over One Pattern). Additional hardware options are required to enable this configuration.

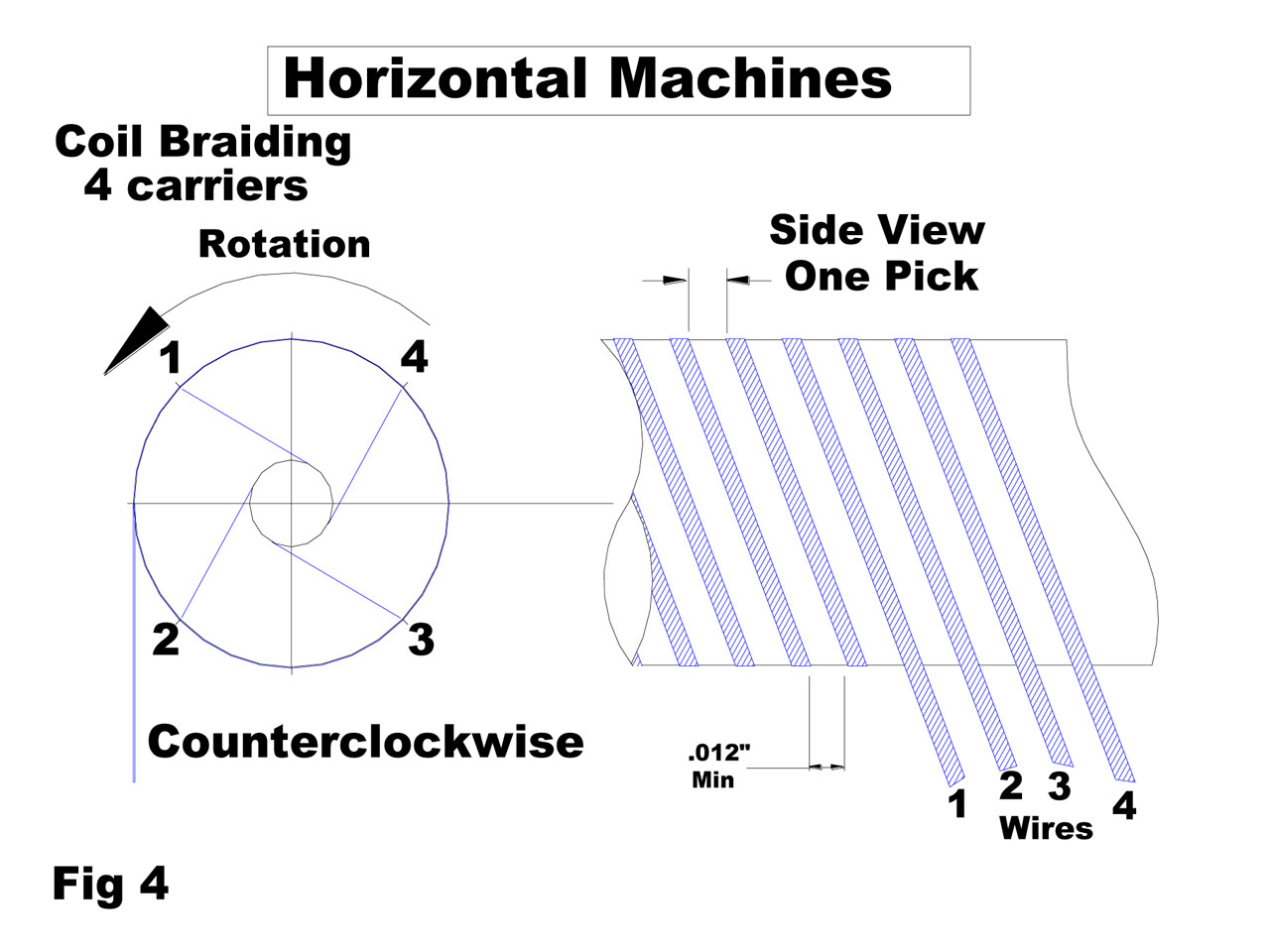

Coil Catheter Braid Pattern

Wires in this braided catheter pattern wound in sequence the same direction to create a coil. Multiple wires can simultaneously be wound together. Lay direction can be clockwise or counter clockwise. Steeger’s coiling machine cannot “Shoulder to Shoulder” the coil.

In these kinds of braided catheter patterns coiling offers kink resistance and will also increase burst strength but does not have pushability.