As part of Machine Solutions, Steeger USA offers the most comprehensive suite of lamination and post- lamination machines. Our lamination machines offer strict process control and repeatability to virtually any heat shrink, reflow or mandrel processing application. Oriented either vertically or horizontally, these highly reliable lamination machines are designed for both R&D and full manufacturing environments, and consistently deliver precisely controlled heated air.

Catheter Laminating Equipment

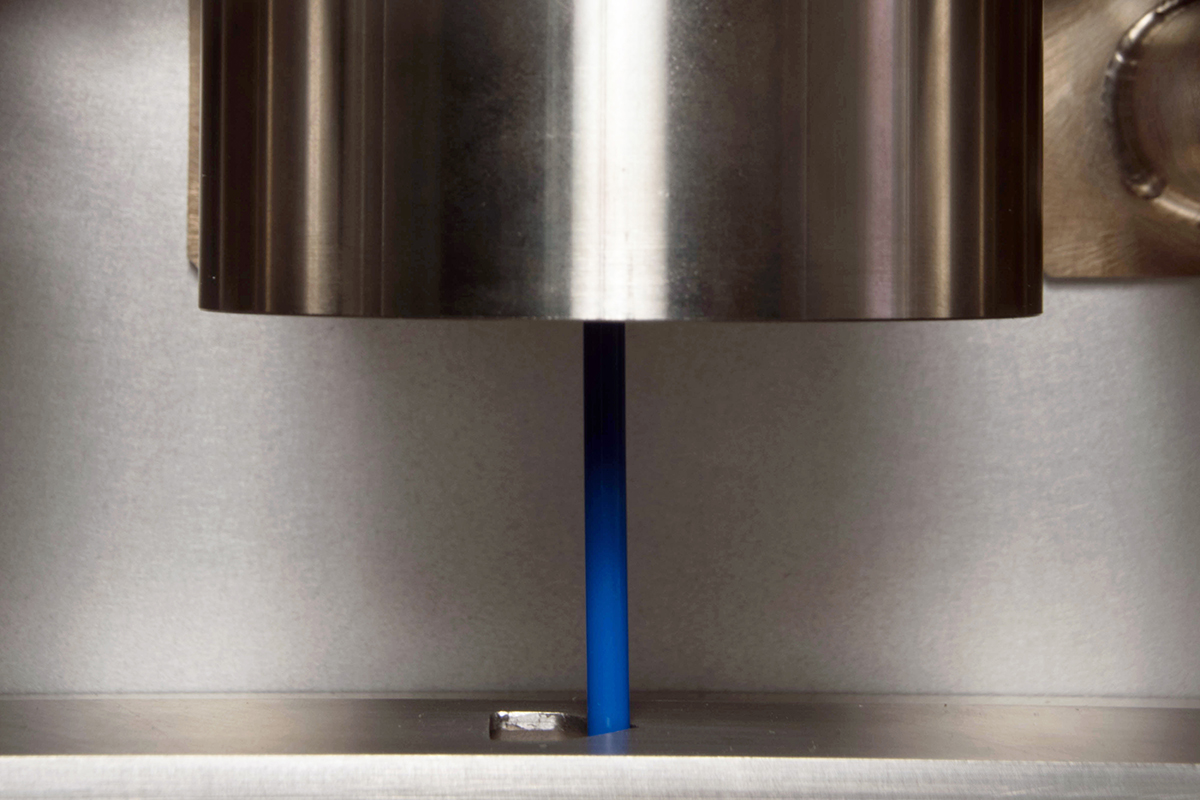

Vertical Laminators

Achieve repeatability and uniformity with our Vertical Laminators (810A, 910A and VL400). Offering an array of thermal nozzle options (including 360 degrees), these lamination machines deliver highly stable, heated air while traversing at a set speed and distance.

With various programming, product loading and product centering options available, our lamination machines can be tailor made to meet your specific requirements.

Learn More

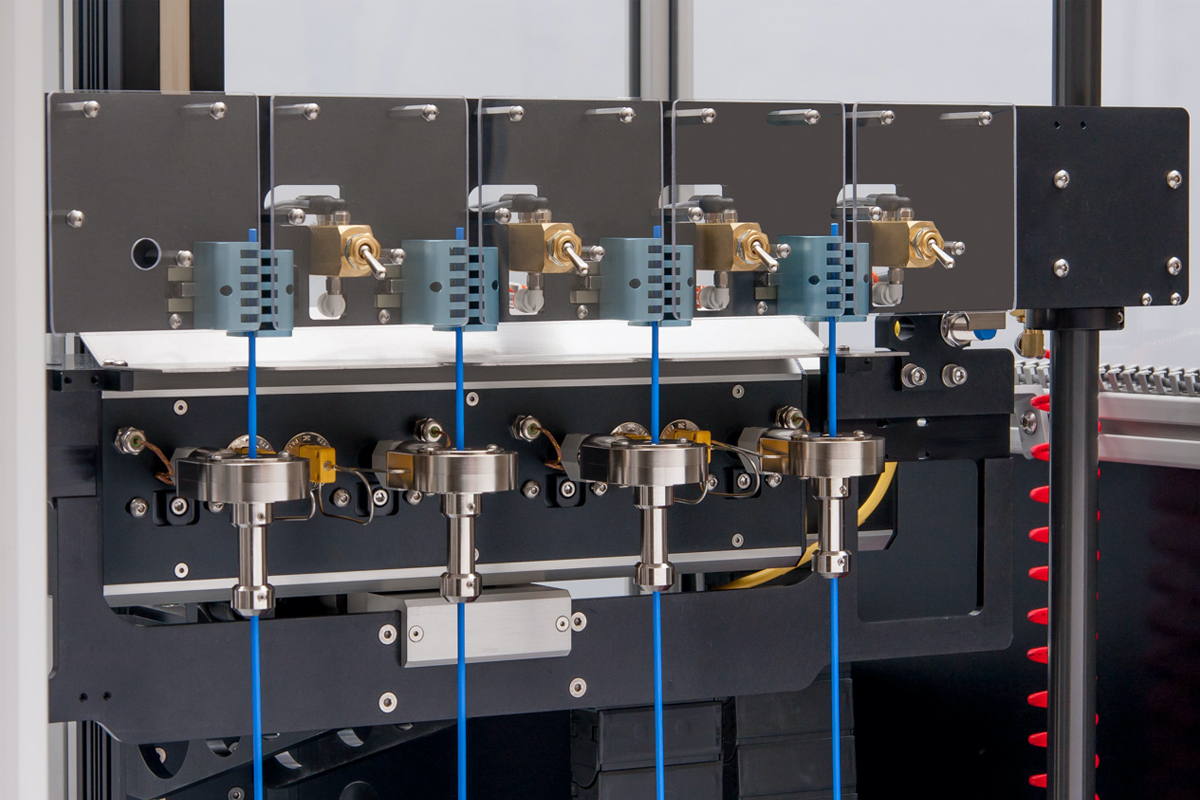

Horizontal Laminators

These semi-automated units channel precisely controlled hot air to shrink, laminate, or reflow thermoplastic materials into a single composite. Featuring either a touch screen HMI with recipe management or a simple keypad interface , these horizontal lamination machines traverse a multi-port thermal nozzle along a specified length. They allow the user to input precise length, speed, and temperature values. A wide range of configurations and options are available to meet the most demanding applications. Capabilities include single or multiple part processing, long shaft lengths and wide speed range. Thermal Traversers (710A), and 410A channel precisely controlled hot air to shrink, laminate, or reflow thermoplastic materials into a single composite.

These lamination machines traverses a multi-port thermal nozzle along a specified length and speed. The 710A touch screen HMI parameter interface provides recipe management and maintenance/parameter access password lock-out. A wide range of configurations and options are available.

Learn More

Mandrel Removing & Stretching

Automate and simplify the laborious task of mandrel removal with our mandrel extraction machines. These machines extract the mandrel from the product shaft I.D. by either drawing the mandrel out at a controlled speed, or stretching the process mandrel to break the resistance created during such processes as laminations, braiding and coil winding. These machines offer three-speed and length program zones, recipe management, configurable product grip spacing are capable of accommodating various lengths and are extremely easy to use. Call us to lighten your work load and to learn how these systems efficiently remove malleable core mandrels such as copper, PTFE and acetals.

Learn More

Heat Shrink Removal

Heat Shrink Removal Tools are one of the most important tools in medical device manufacturing to prevent skive damage. These handy tools are used to peel and remove heat shrink from mandrels and tubing assemblies. Our heat shrink removal solutions are used to minimize operator processing time and increase overall performance of products. Featuring specialized composite blades, these tools are far superior to that of stainless razor blades which quickly oxidize after a few uses.

Learn More