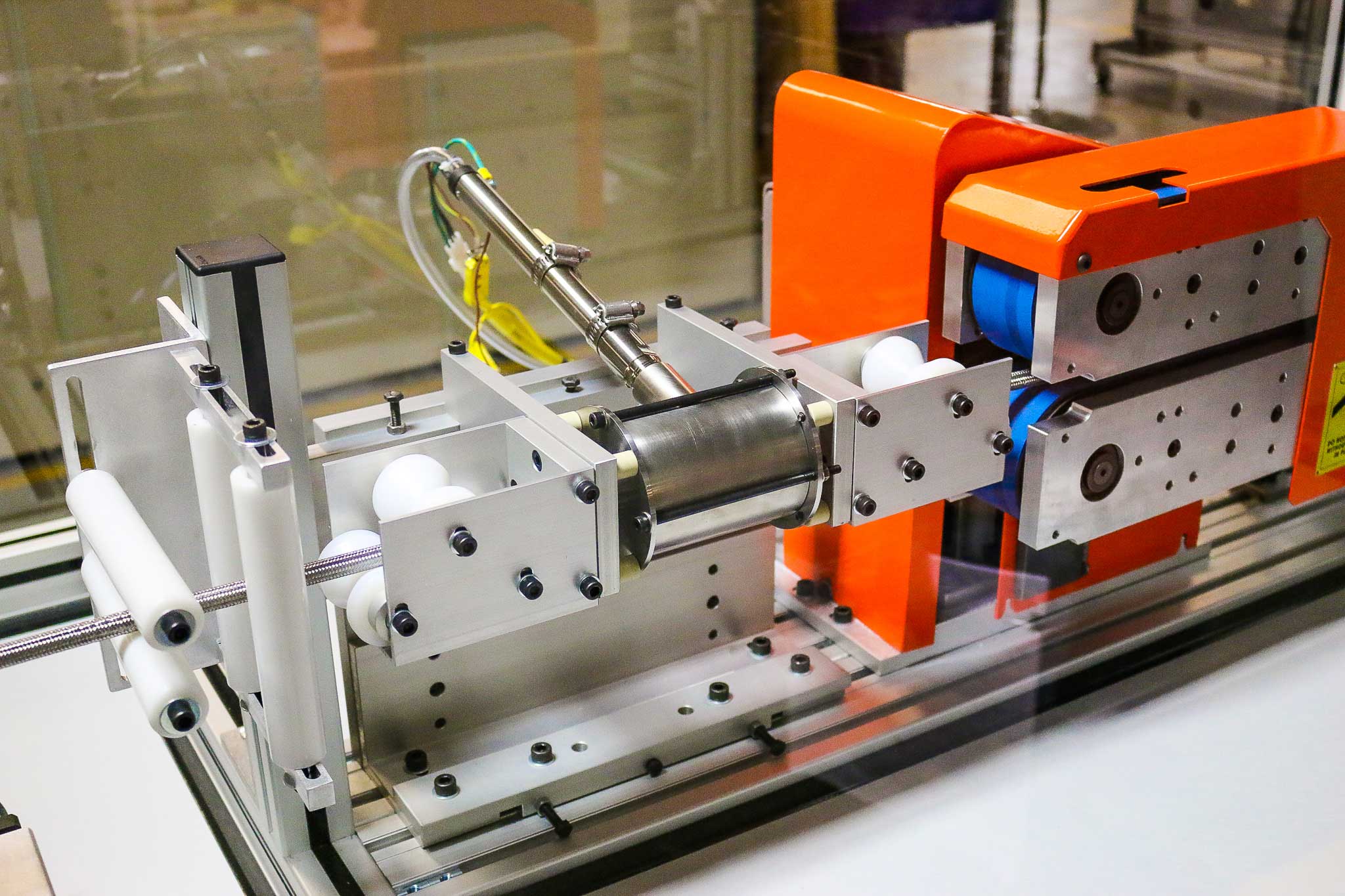

Textile Reinforced Balloon Braider

Advanced Technology for High-Performance Medical Balloons

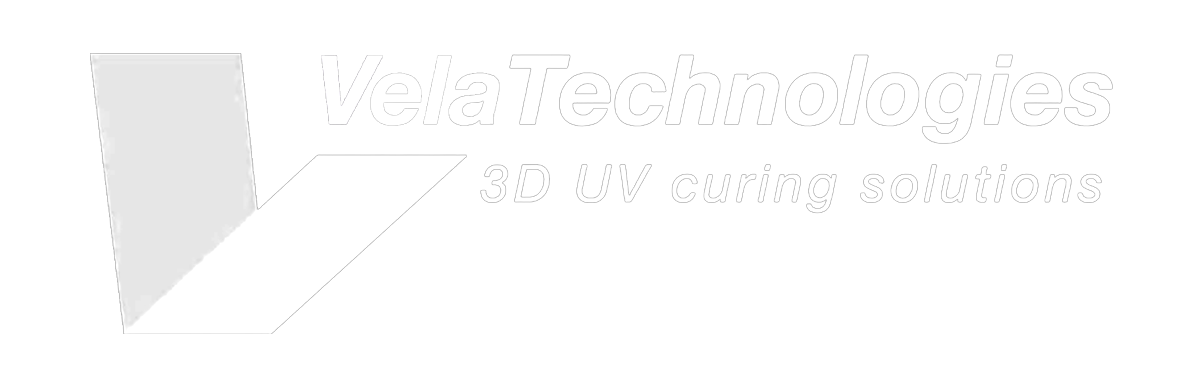

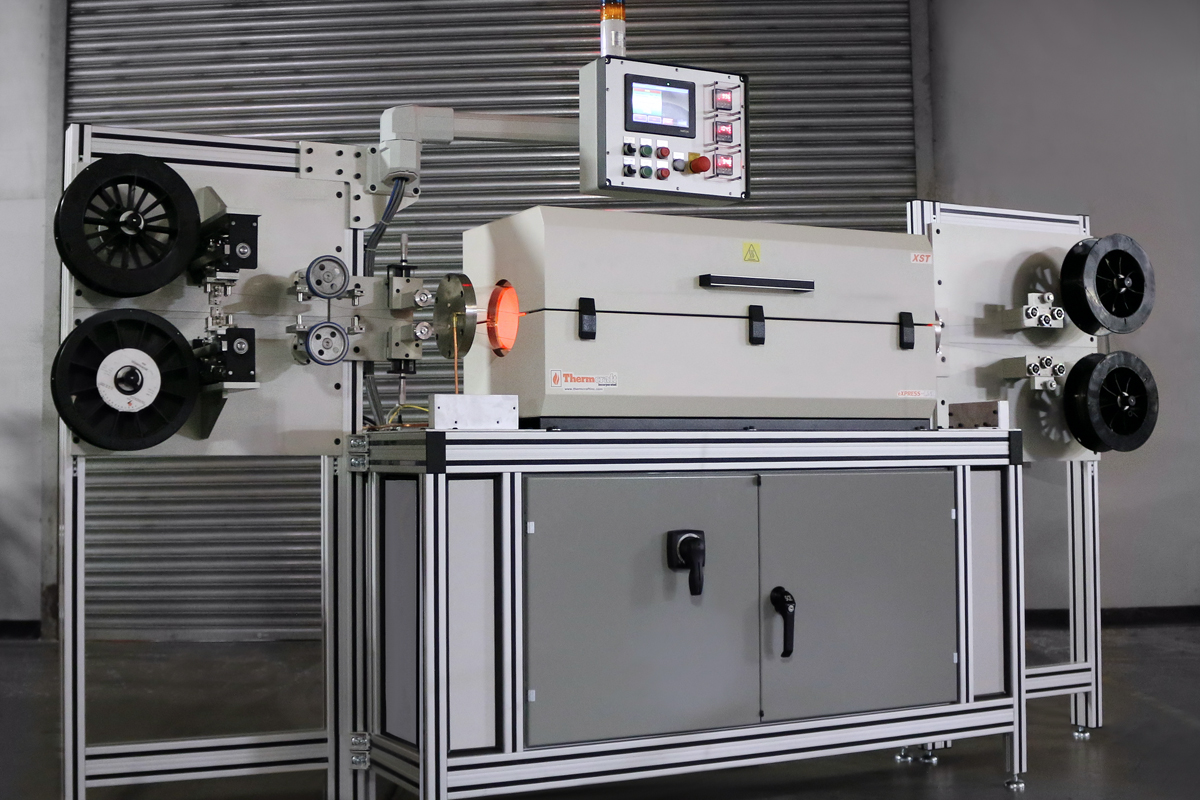

Steeger’s textile reinforced balloon braider revolutionizes medical balloon manufacturing by integrating advanced braided structures into multi-layer designs. This cutting-edge equipment enhances the strength and burst pressure of medical balloons while maintaining a low profile and flexibility, setting a new standard in reinforced medical balloon production.

The Power of Steeger Braiding Technology

Traditional medical balloons, made from materials such as nylon, PEBA, or PET, are limited by single-layer designs. Steeger’s textile braider addresses this limitation by incorporating a custom braid structure into the balloon fabrication process. This innovation enables manufacturers to achieve higher burst pressures and superior durability without compromising flexibility.

Key Features of the Textile Reinforced Balloon Braider

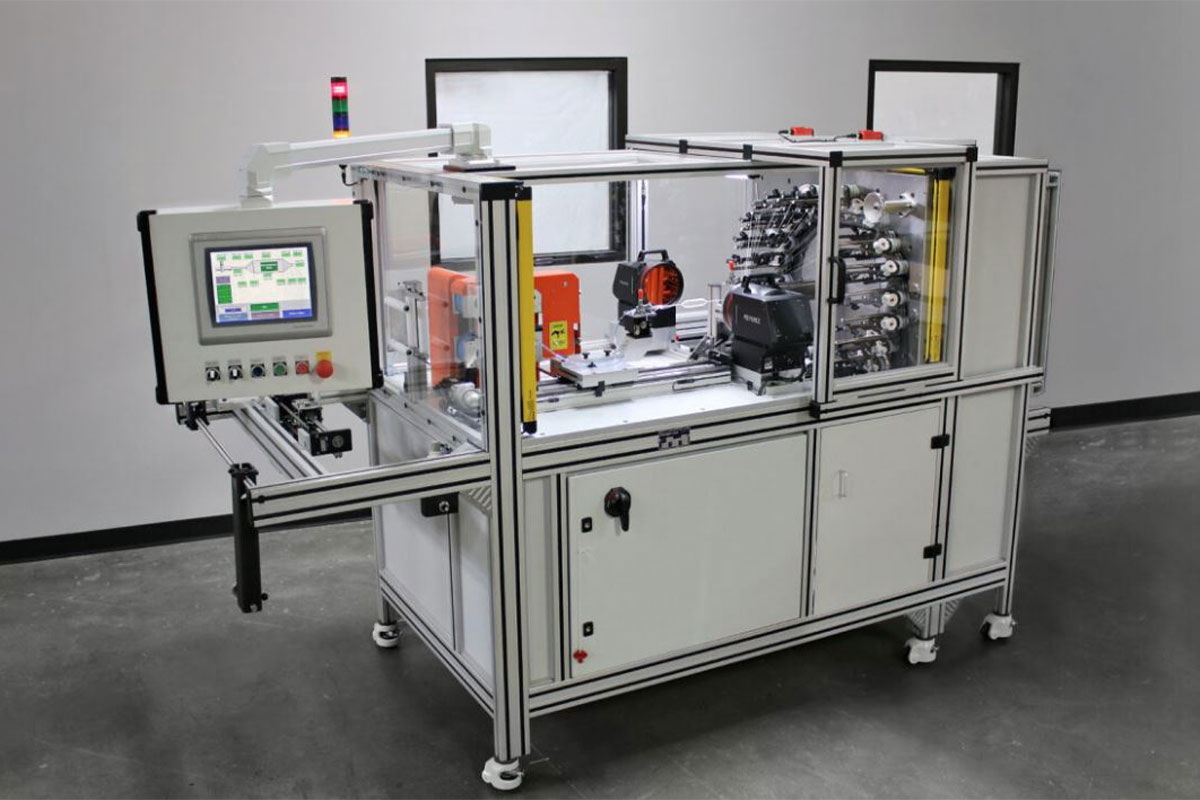

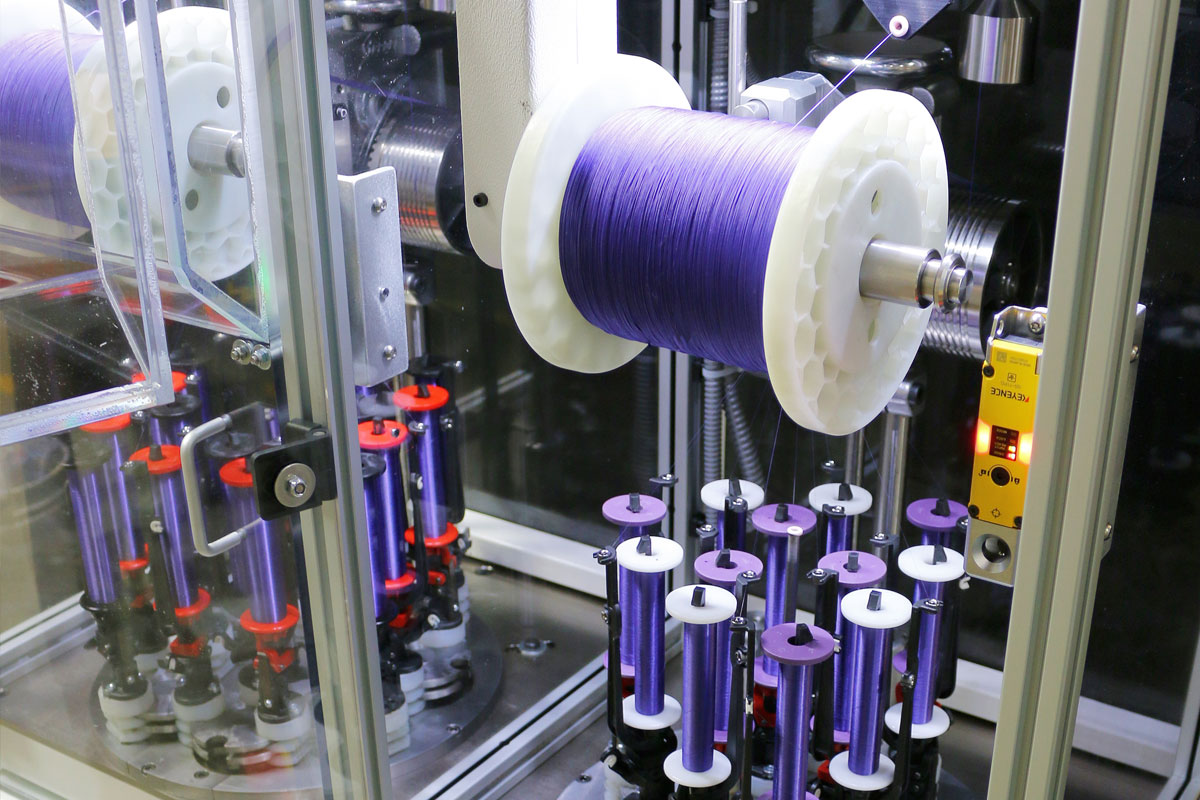

- High-Tensile Braid Materials: Designed to work with continuous filament and monofilament fibers for producing high-strength, low-compliance balloons.

- Customizable Braid Parameters:

- Fiber Denier (Thickness): Adjust for strength and performance.

- Pick Count & Fiber Angle: Fine-tune the braid pattern for optimal burst pressure.

- Tri-axial Integration: Incorporates longitudinal structural elements braided in and out of every crossing for additional durability.

- Scalable Braid Count: The braider accommodates a wide range of braid patterns and counts, with tri-axials comprising up to 50% of the total carriers, ensuring versatility for various balloon designs.

Superior Performance Through Precision

The textile reinforced balloon braider enables precise control over the manufacturing process:

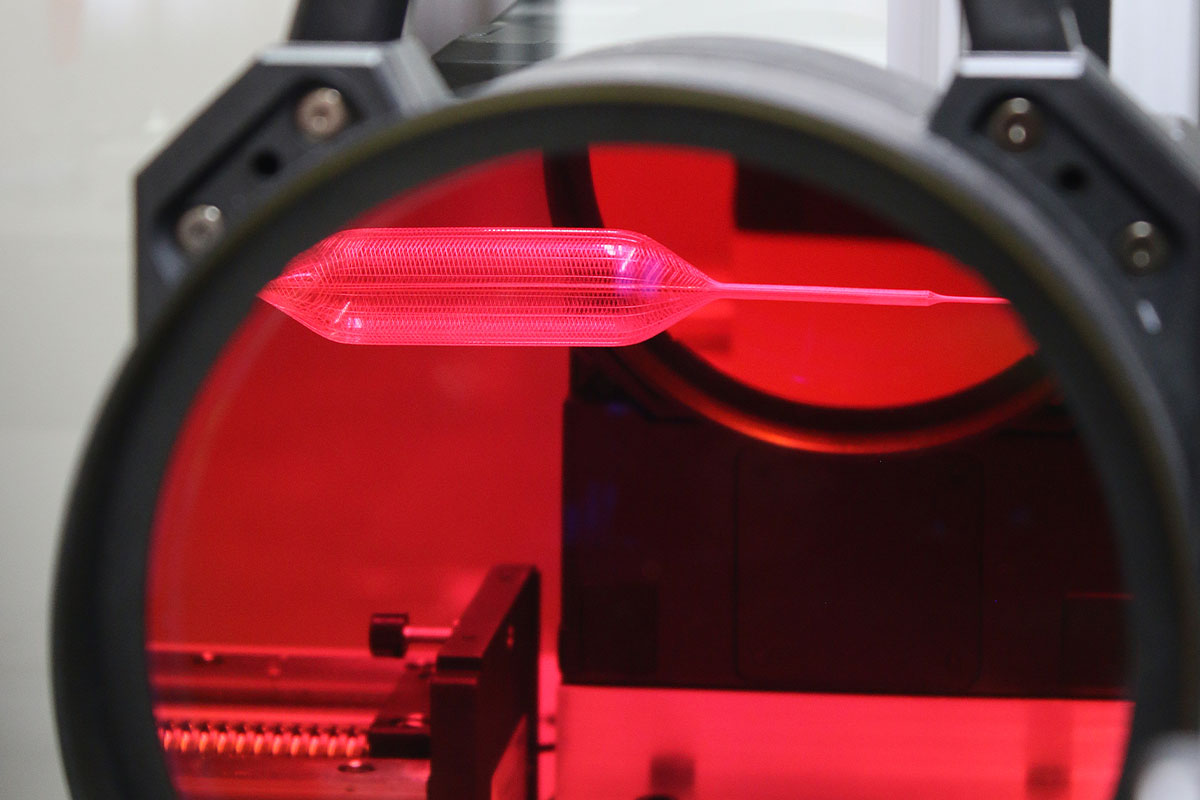

- Optimized Strength: Increase fiber denier and braid count to achieve unmatched burst pressures.

- Customizable Patterns: Adjust the braid angle and count to meet the exact specifications for each application.

- Enhanced Durability: Incorporate tri-axials seamlessly into the braid structure, reinforcing the balloon without adding bulk.

Why Choose Steeger’s Braiding Technology?

Steeger’s textile reinforced balloon braider empowers manufacturers to push the boundaries of medical balloon performance. Its advanced features allow for precise customization, ensuring consistent, high-quality results that meet rigorous industry standards.

Transform your balloon production with Steeger’s textile reinforced balloon braider. Contact us today to explore how this technology can elevate your manufacturing capabilities!

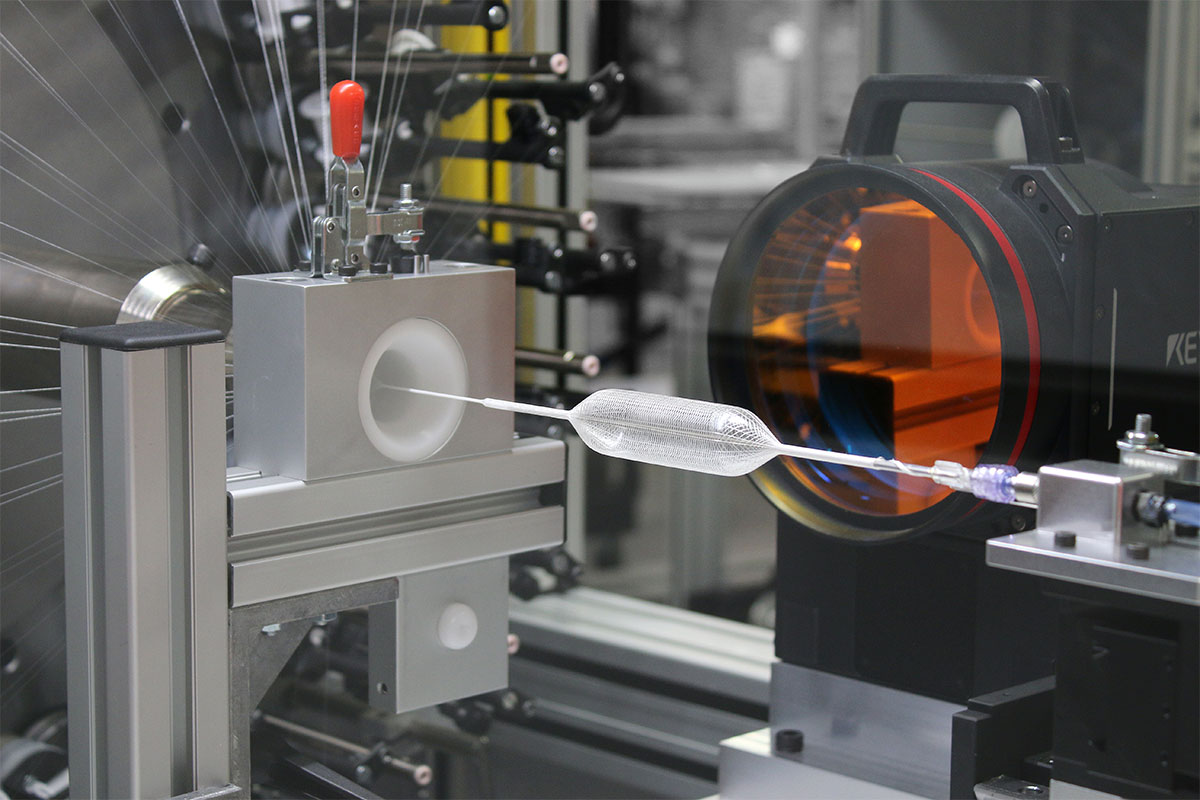

Product Features:

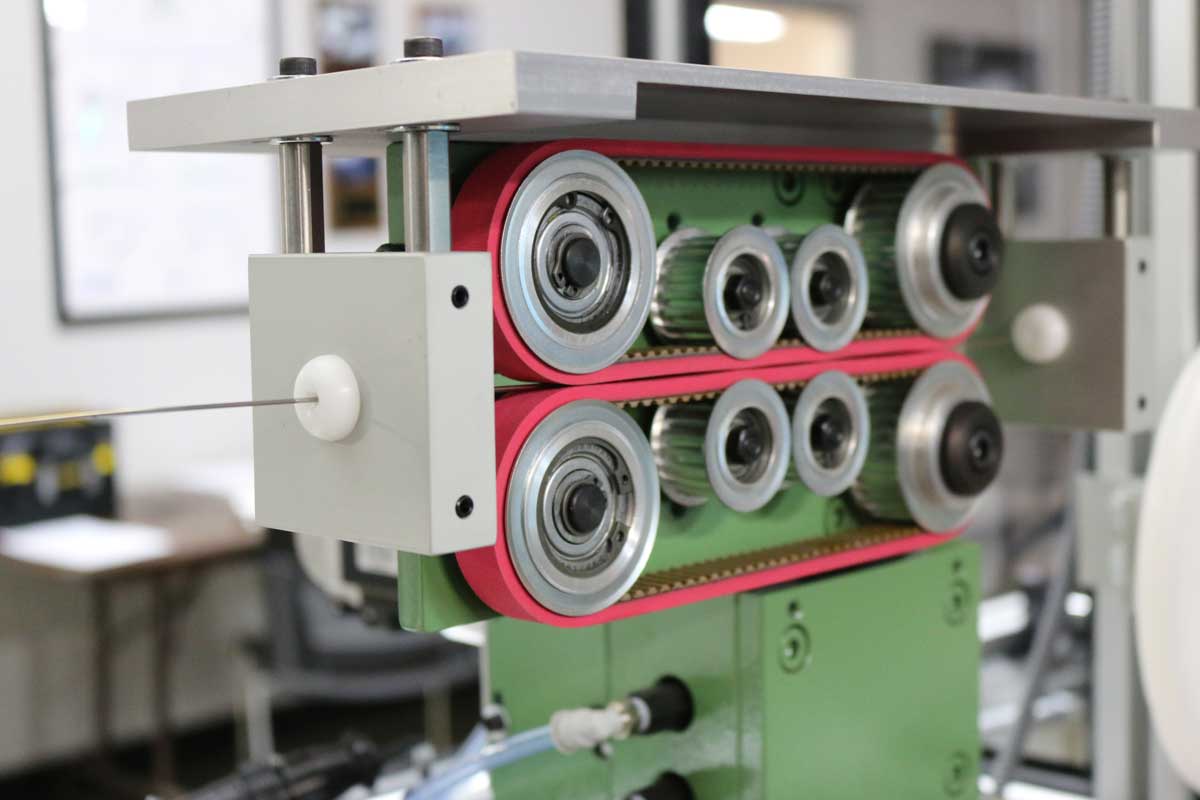

- Efficient pick count transitions along the length and OD changes of the balloon structure.

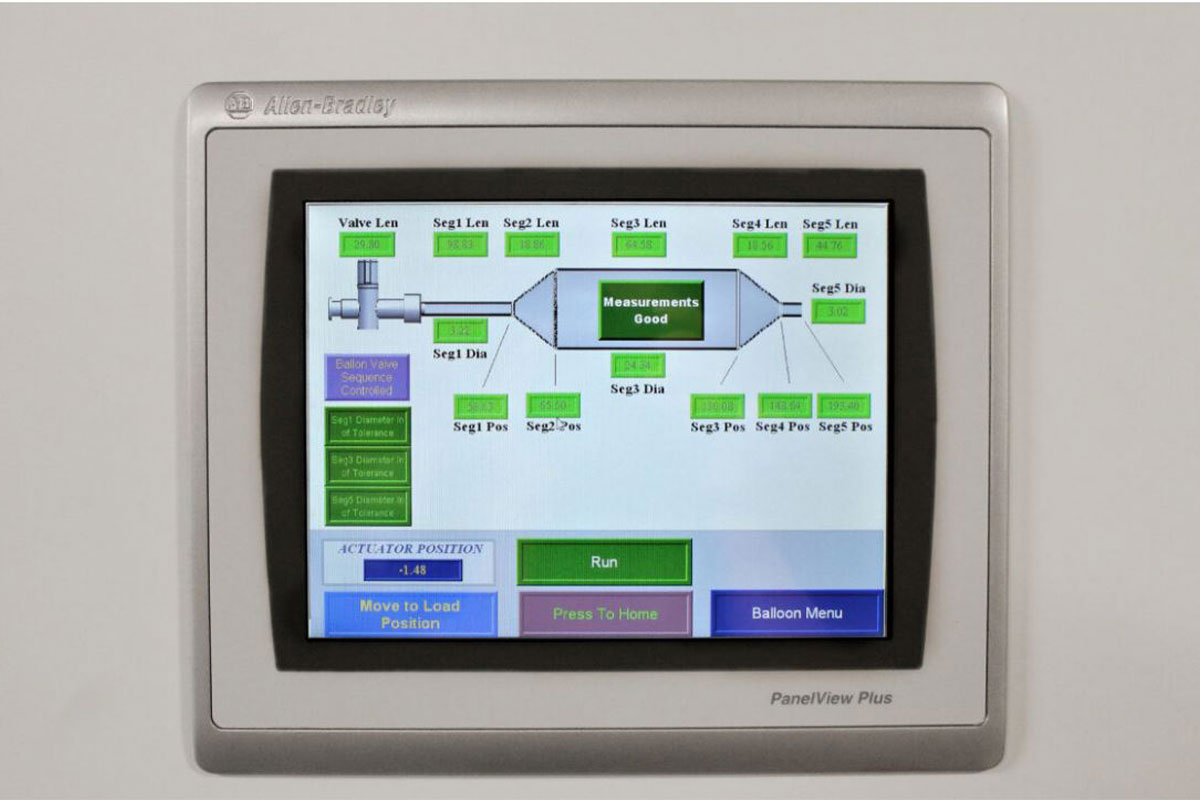

- Balloon Parameter and Measurement Visibility

- Triaxial tubes, wire break detectors, carrier mounts, and KL80d carriers included.

- Telecentric Measurement

- Ultra Precise Process Control