Bobbin Winding Machines

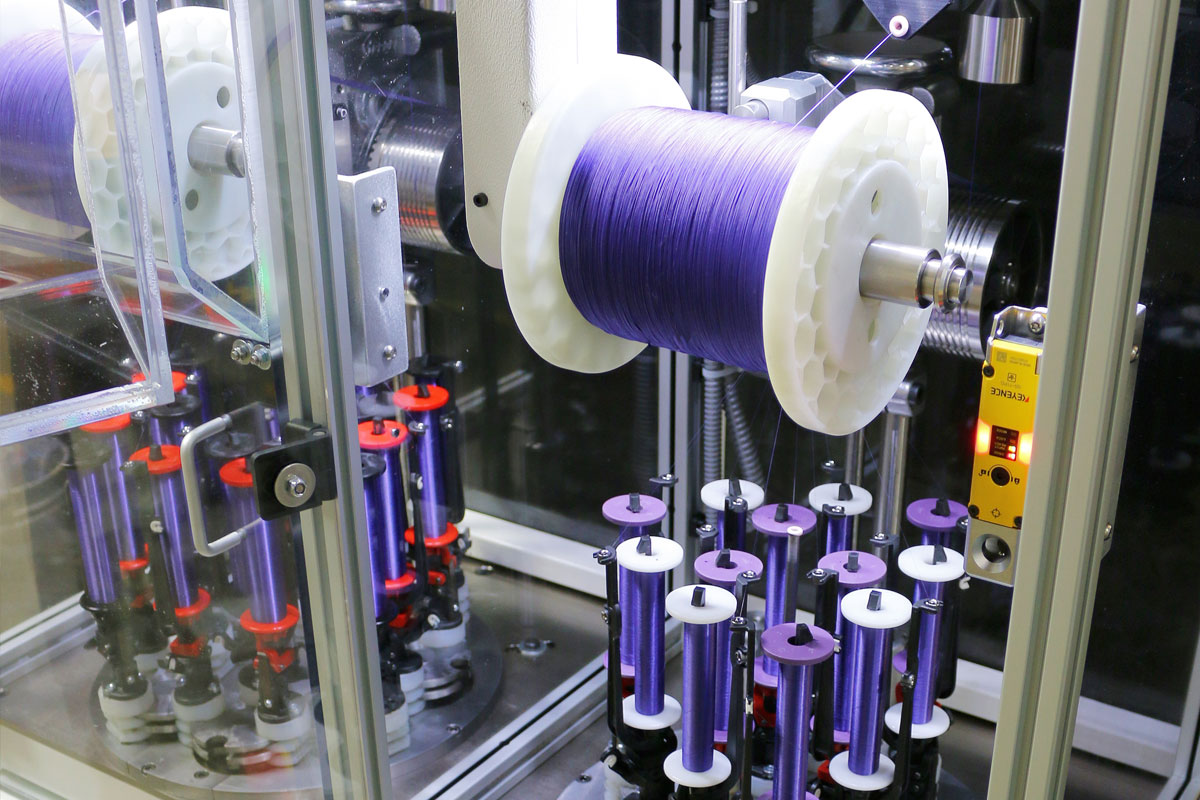

Optimize Your Bobbin Winding Process for Superior Braiding

“Quality Braiding Starts at the Spool”

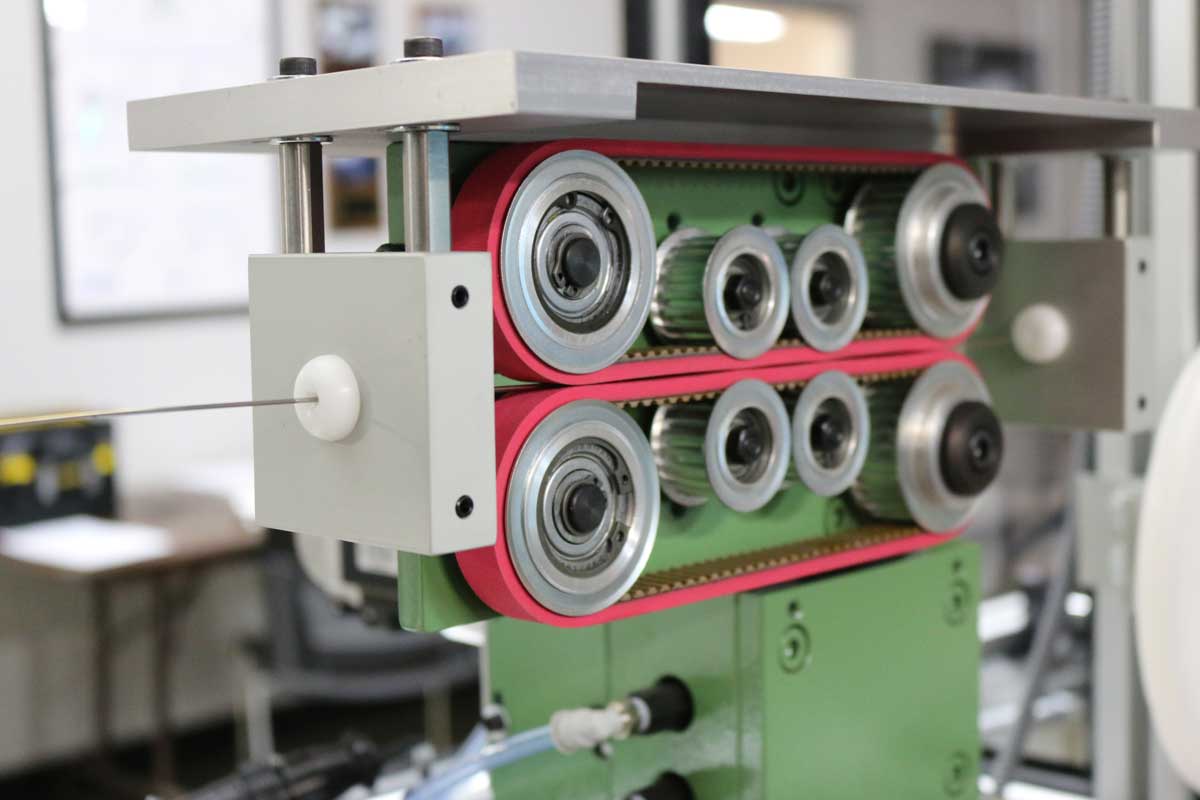

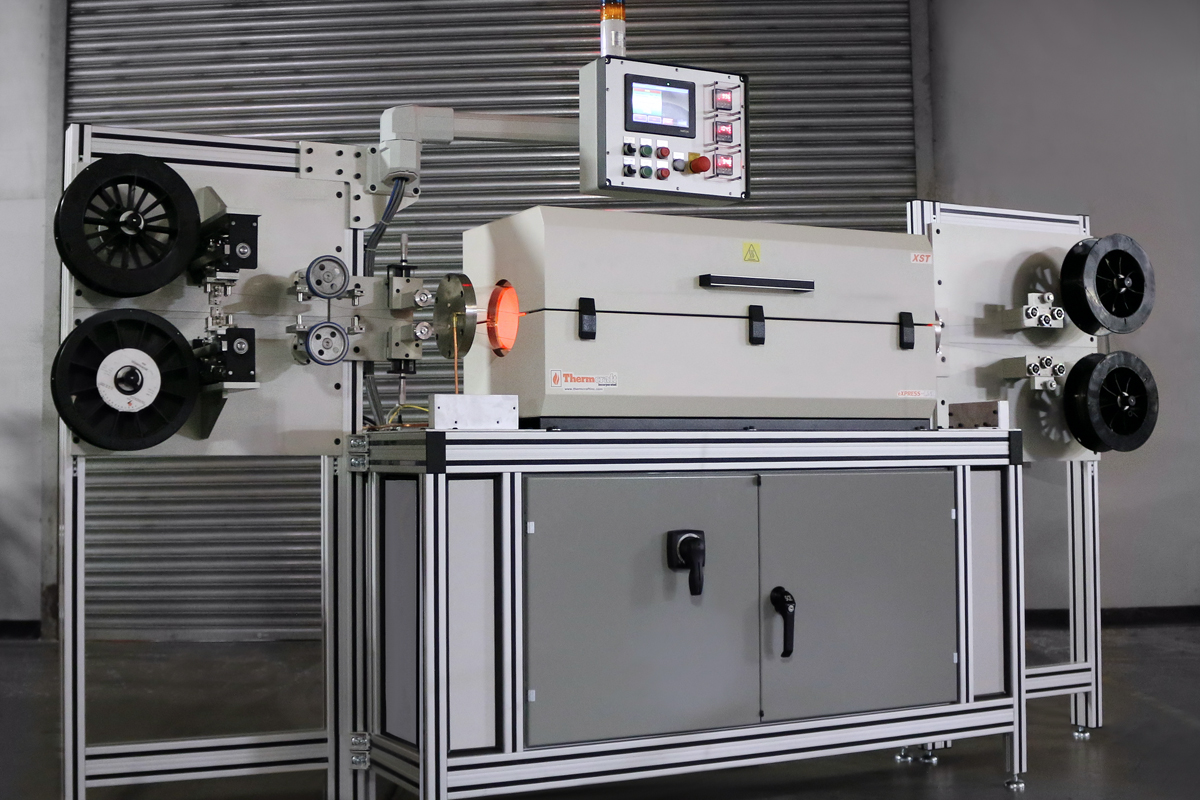

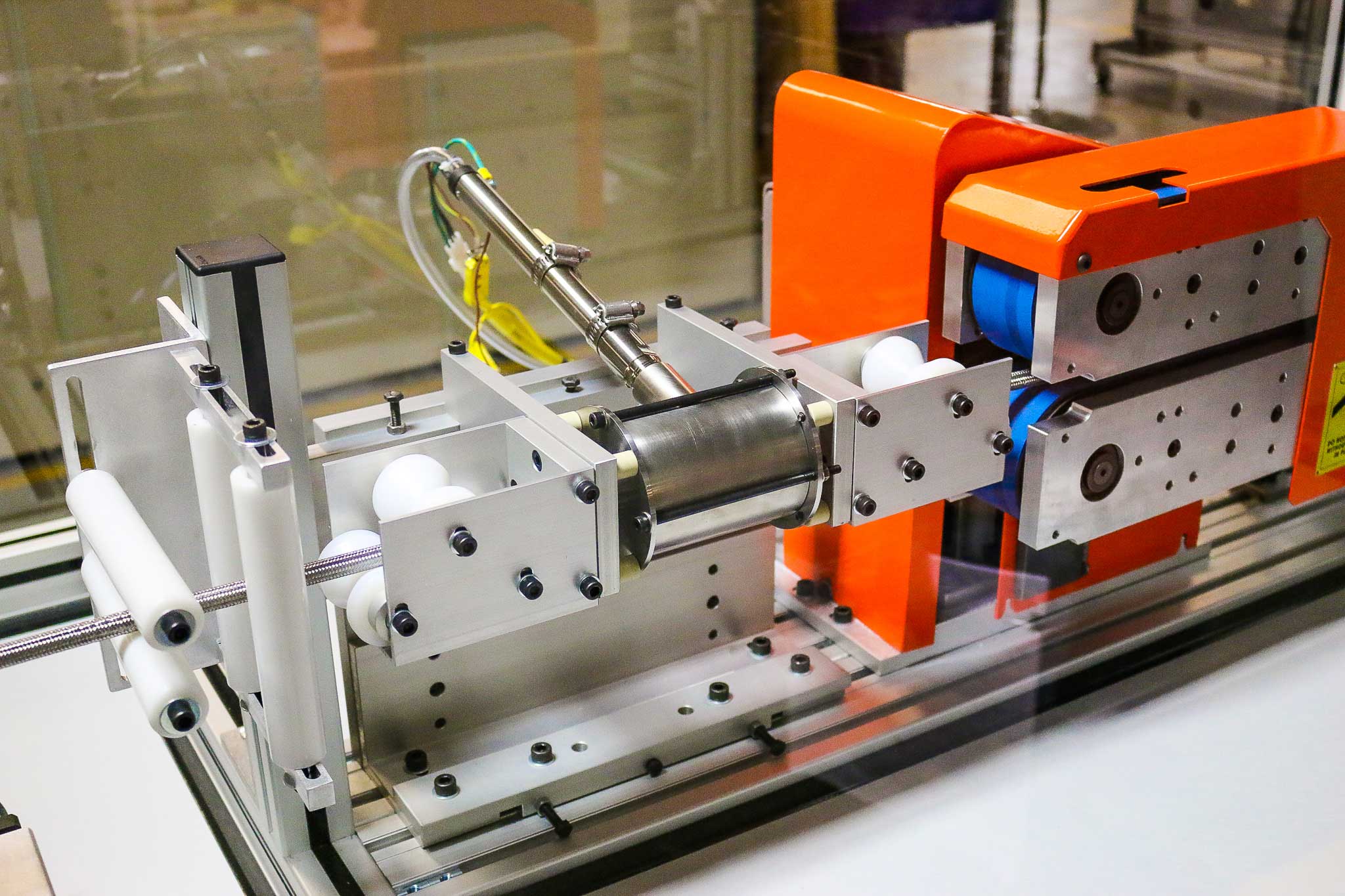

Achieving flawless braid-reinforced medical tubing begins with a precise and efficient bobbin winding process. Steeger USA’s advanced bobbin winding solutions are specifically engineered to prevent tangles, breaks, kinks, and twists during the braiding process, ensuring optimal performance and consistency.

Why Choose Steeger USA for Bobbin Winding?

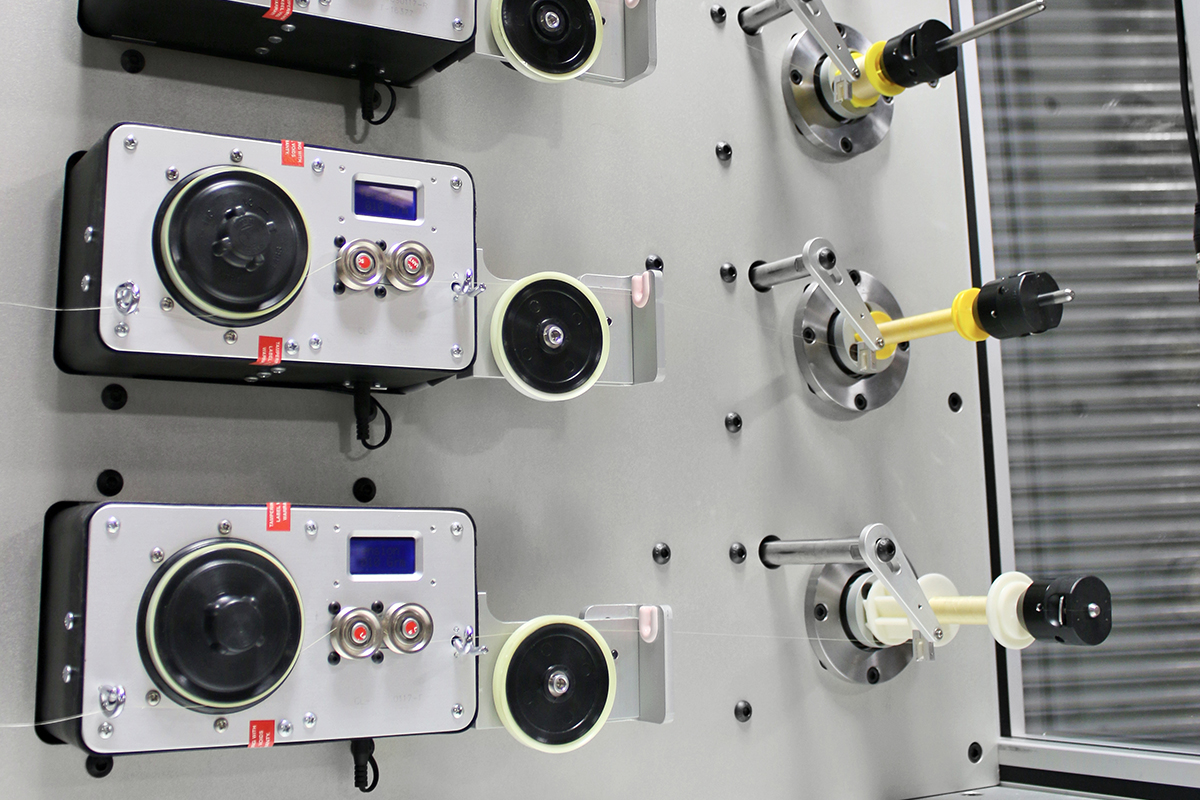

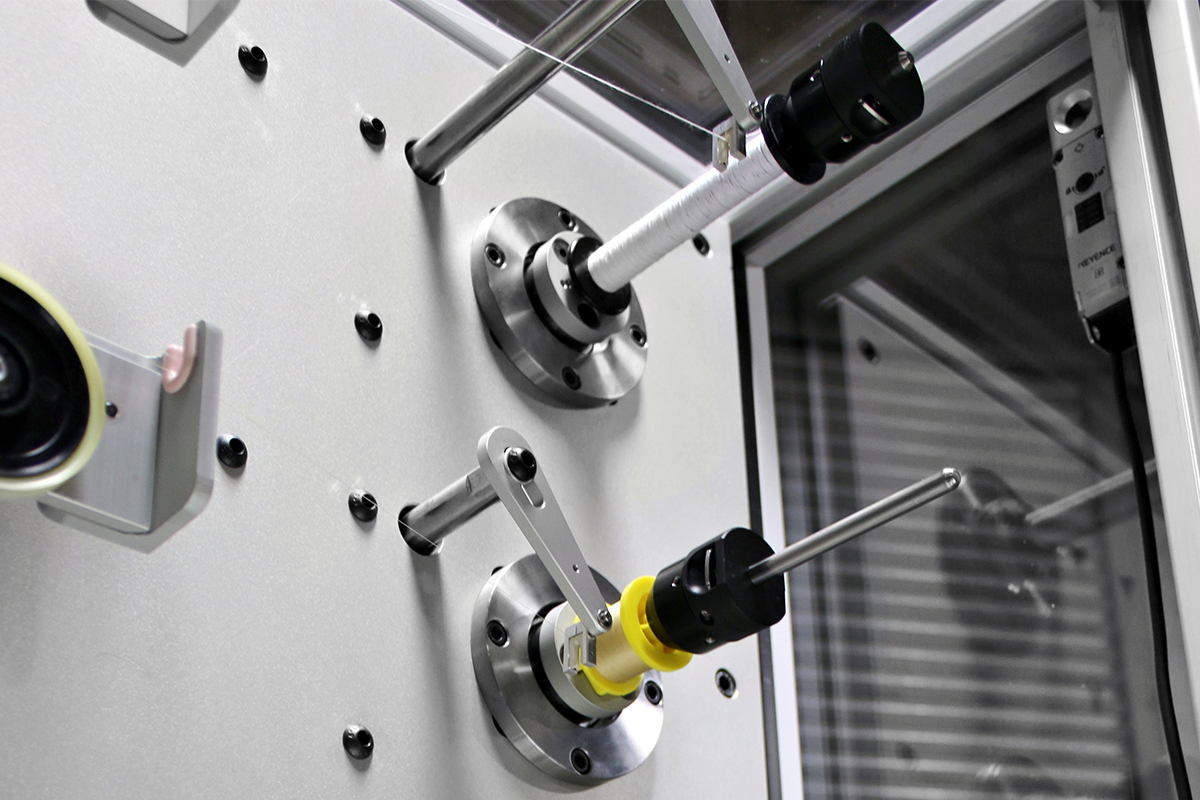

Our bobbin winding machines deliver unparalleled accuracy, ensuring material is evenly loaded onto the spool with precise tension control and strict adherence to process parameters. These CE-compliant machines accommodate a wide range of customer-specific requirements, including:

- Bobbin Loading Capacity: Customizable for different quantities.

- Ends Per Bobbin: Tailored to specific braiding needs.

- Tension Load Ranges: Adjustable to ensure ideal tensioning for various materials.

- Material Payoff Reel Sizes: Supports diverse material formats for seamless integration.

Materials Supported by Steeger USA’s Bobbin Winding Machines

Our solutions are versatile, designed to handle a wide range of materials used in medical tubing applications:

Continuous Fibers and Monofilaments:

- Polyester

- PEEK

- LCP

- Vectran

- Dyneema

- Nylon

Fine Wires:

- Stainless Steel

- Copper

- Nitinol

- Tungsten

- Iridium

- Cobalt Chromium

- Platinum

The Steeger USA Advantage

By starting with a high-quality bobbin winding process, you set the foundation for precision braiding, enabling the production of superior braid-reinforced medical tubing. Steeger USA’s advanced technology ensures reliable, repeatable results for even the most demanding applications.

Features and Capabilities:

- Recipe Driven Controls – Adjustable Speed, Acceleration, Deceleration Tension, Pitch & Start/End Positions.

- Break Detection

- Length Counters

- Tension Feedback

- Protective Guarding

- Can Wind on Virtually Any Bobbin Type

- Accommodates up to DIN200 Payoff Reel Size

| Specifications: | |||

|

Bench Top Single End, Single Spindle |

Dual Spindle, Multiple End Type |

Four Spindle, Multiple End Type |

|

| Machine Model |

SWM-001 |

SWM-002 |

SWM-004 |

| Maximum Speed |

400 Ft/Min |

400 Ft/Min |

400 Ft/Min |

|

Maximum Traverse (Pay Off) |

160mm | 160mm |

160mm |

|

Maximum Traverse (Wind Up) |

130mm |

130mm |

130mm |

|

Maximum Flange (Pay Off) |

200mm |

200mm |

200mm |

|

Maximum Flange (Wind Up) |

66mm |

66mm |

66mm |

|

Tension Range |

10-500g |

10-500g |

Variable |

|

Tension Feedback |

Yes |

Yes |

Yes |

|

Savable Spool Parameters |

Yes | Yes |

Yes |

|

Savable Recipes |

Yes |

Yes |

Yes |