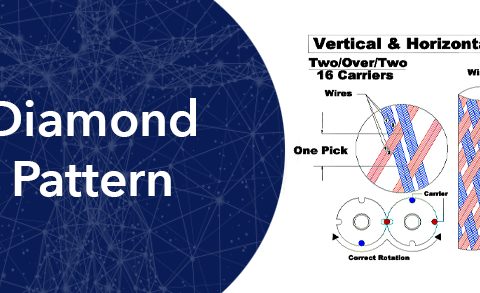

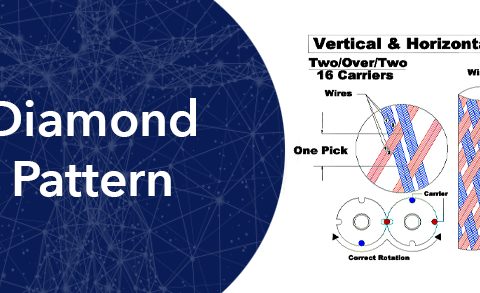

Diamond Pattern for Torqueability & Kink Resistance

Original post:

There are a number of different kinds of braid patterns designed for different application purposes and complexities. If you’re looking for torqueability, kink resistance or full coverage within your braiding production, you would use the Diamond full load and round wire material. To learn more about the specification about the diamond pattern and other available […]

Read More

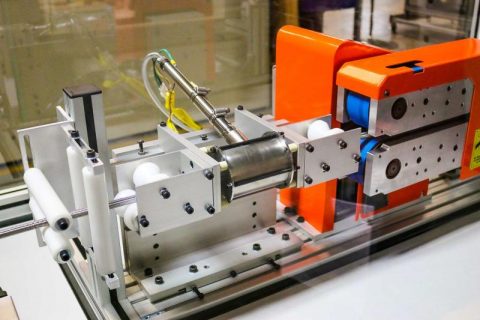

Steeger USA;s In-Line Heating Elements

Original post:

SteegerUSA has experience integrating a variety of in-line heating elements within our braiding system on both pre and post braiding applications. These heaters can be used in applications that require material bonding and mandrel indentation. Our braiders pair well with the MSI Micro-swirl 360 heater nozzles and in some cases clam shell heaters for really […]

Read More

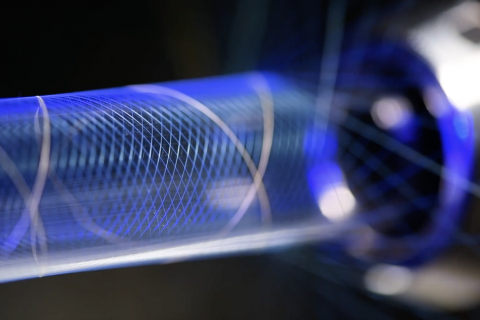

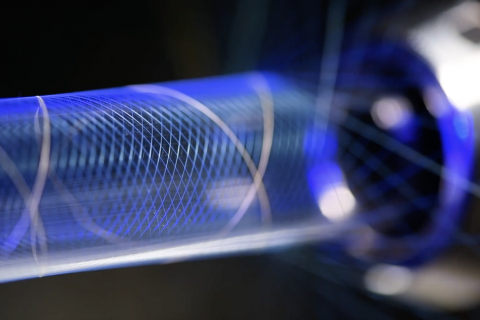

Bioabsorbable Braiding

Original post:

Steeger braiders can run at higher speeds with less time-consuming wire breaks than our competitors. Our machines provide a platform for the customization our customers need in connection with their high tech and demanding applications. Biogeneral uses a 96 carrier machine to braid fibers as small as 0.0006” diameter. They have 30+ years of experience […]

Read More

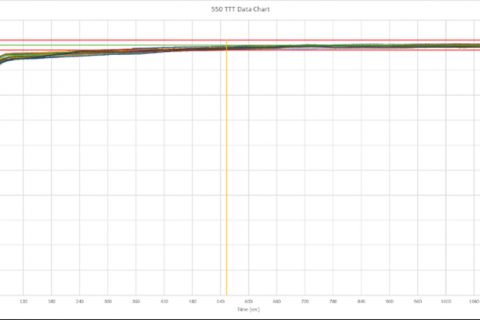

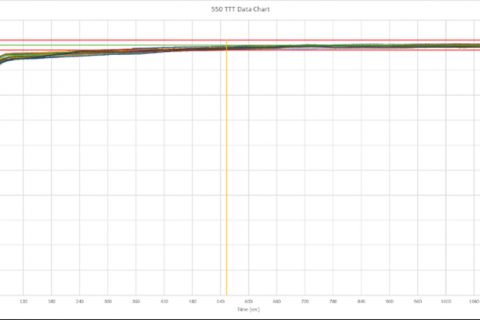

Vertical Lamination Temperature Stability & Repeatability

Current state: Rudimentary and legacy market heating methods with larger windows of variability have been accepted to accomplish basic lamination needs for catheter manufacturing. As the industry grows, material and designs become more complex, along with increased requirements for process and equipment validation, higher precision controls are required. In response to the industry demand for [...]

Current state: Rudimentary and legacy market heating methods with larger windows of variability have been accepted to accomplish basic lamination needs for catheter manufacturing. As the industry grows, material and designs become more complex, along with increased requirements for process and equipment validation, higher precision controls are required. In response to the industry demand for [...]

Read More

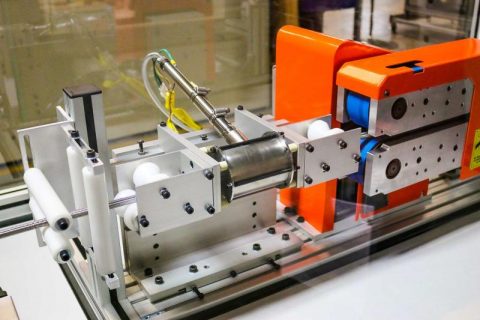

Standard Coiling Machine

Original post:

The Standard Coiling Machine can coil up to 16 carriers of material (16 Ends), onto a continuous core or discrete mandrels that range from 0.0005” to 0.3” in diameter. These coiling units can be built in a vertical or horizontal style. To learn more visit https://lnkd.in/gjz7Ejn

Read More

Current state: Rudimentary and legacy market heating methods with larger windows of variability have been accepted to accomplish basic lamination needs for catheter manufacturing. As the industry grows, material and designs become more complex, along with increased requirements for process and equipment validation, higher precision controls are required. In response to the industry demand for [...]

Current state: Rudimentary and legacy market heating methods with larger windows of variability have been accepted to accomplish basic lamination needs for catheter manufacturing. As the industry grows, material and designs become more complex, along with increased requirements for process and equipment validation, higher precision controls are required. In response to the industry demand for [...]