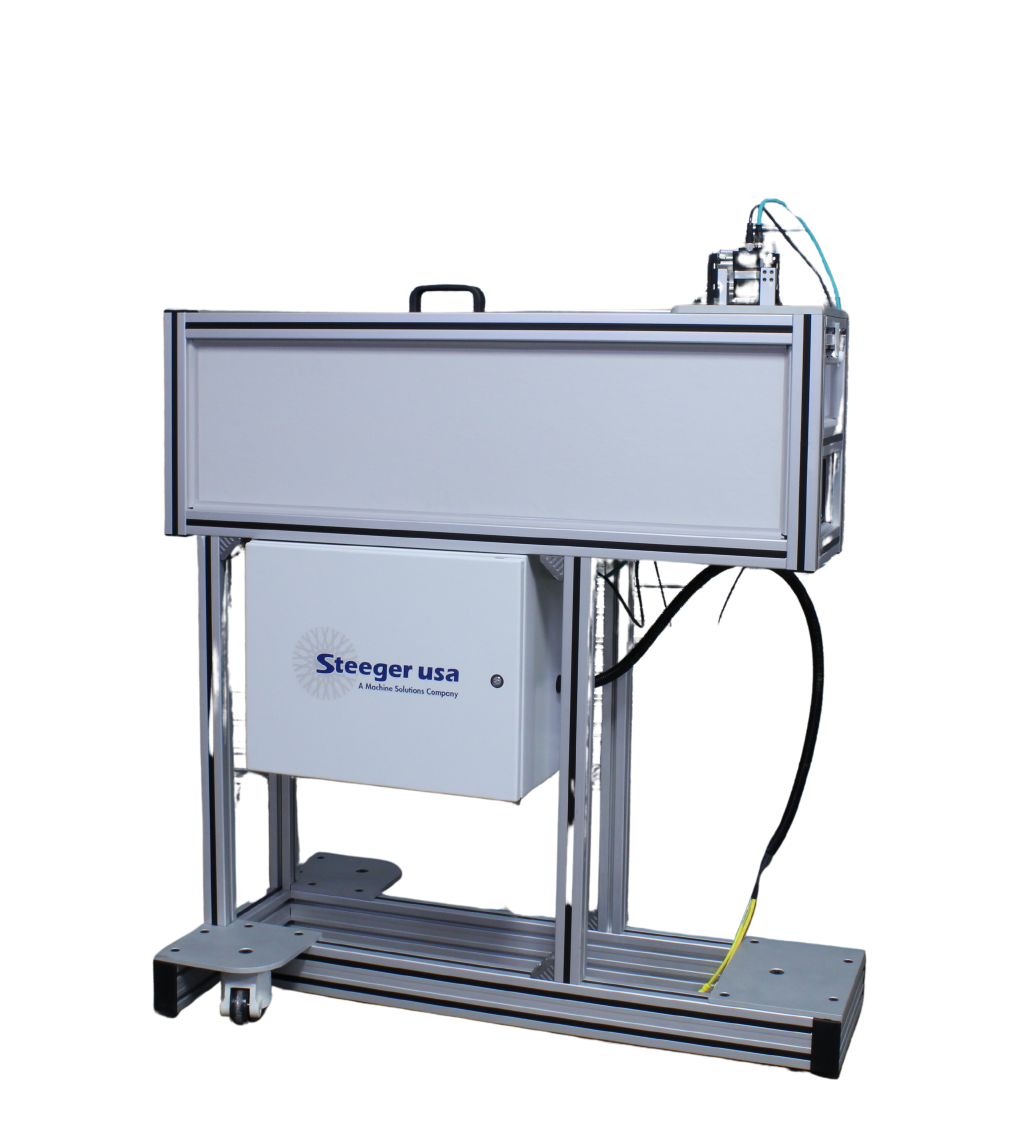

Automated Mandrel Feeding System

Boost Efficiency & Achieve Consistent, High-Quality Results

Steeger USA’s Automated Mandrel Feeding System revolutionizes mandrel handling by minimizing operator interaction and maximizing efficiency. Designed for seamless integration with horizontal braiding machines, this semi-automatic solution eliminates up to 95% of manual intervention in the braiding process. From loading unbraided mandrels to precise cutting and collection, this system is engineered to optimize production workflows while maintaining superior quality.

Why Choose the Steeger Automated Mandrel Feeding System?

- Increased Efficiency: Reduces operator intervention to loading and unloading tasks.

- Enhanced Accuracy: Position sensors and automated cutting ensure precision.

- Customizable Design: Tailored lifting mechanisms and trays support various mandrel sizes and materials.

- Integrated Workflow: Automated feeding, cutting, and collection ensure a streamlined process.

Key Features

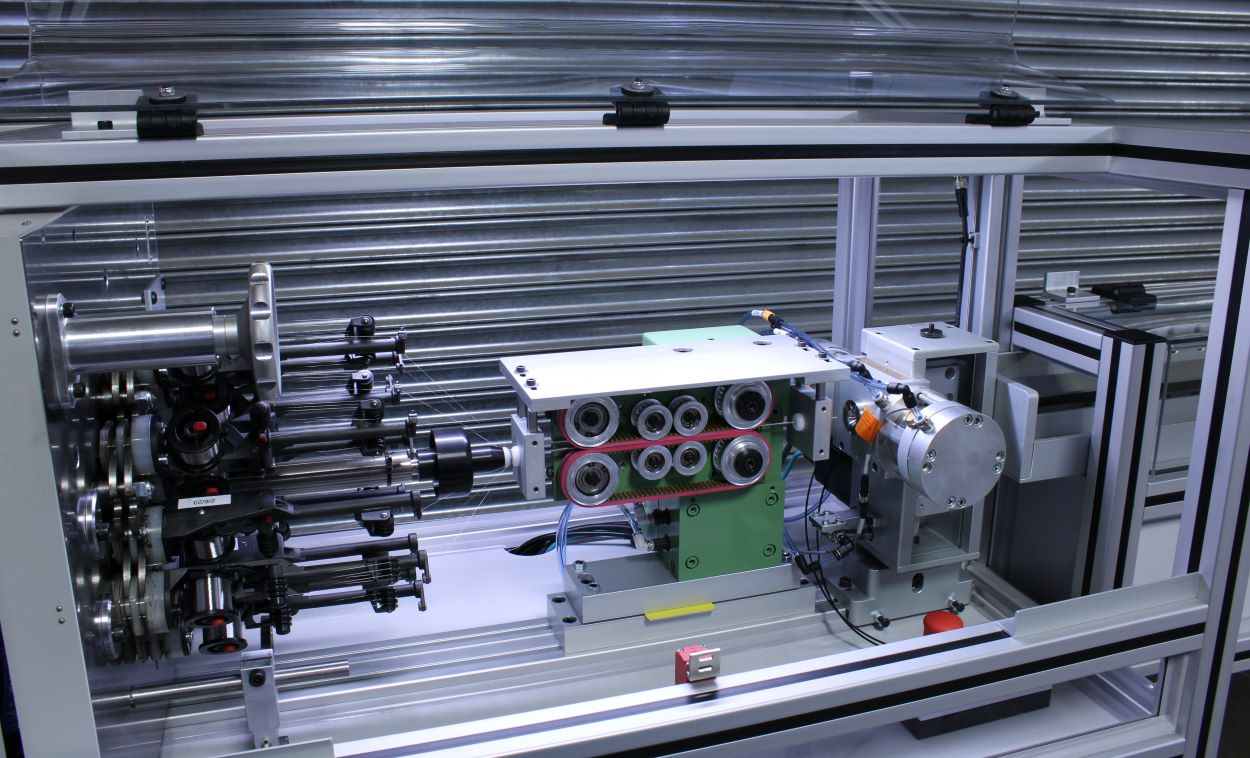

- Automatic Infeed Assembly

- Singulates and feeds mandrels into the braiding machine.

- Adjustable lifting mechanisms for flexible or rigid parts.

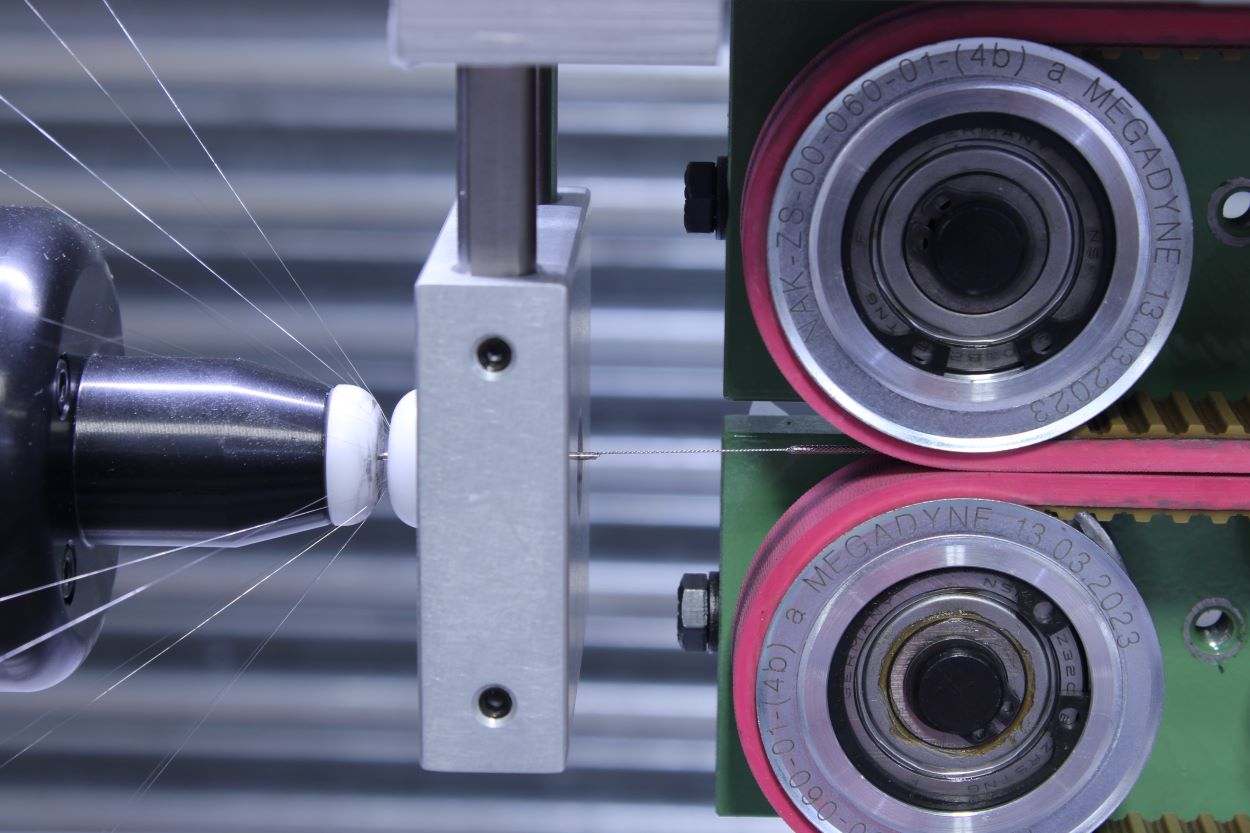

- Air-actuated guides and a pinch-feed roller ensure precise positioning.

- Mounted on casters for easy alignment and movement.

- Limitations:

- Supports mandrels up to 1m in length (upgradeable to 2m).

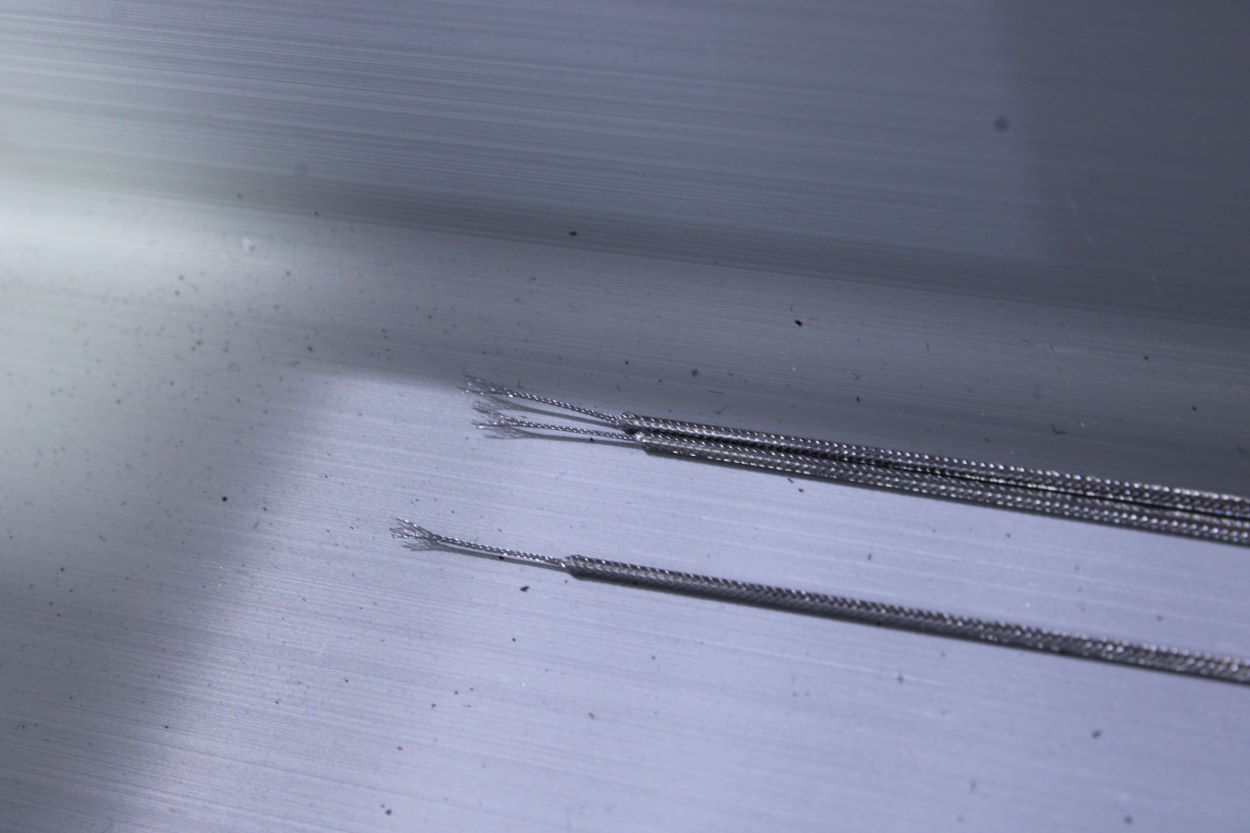

- Diameter range: 0.5mm to 8mm.

- Pneumatic Cutting Assembly

- Precisely separates mandrels with high-force pneumatic cylinders.

- Integrated belt puller maintains tension and ejects the cut mandrels.

- Capable of cutting through braid and mandrel for specific applications.

- Limitations:

- Mandrel diameter range: 0.5mm to 8mm.

- Isolation Tray and Collection Assembly

- Ensures finished mandrels are separated to prevent product interference.

- Supports mandrels up to 1m in length (upgradeable to 2m).

- Batch quantities tailored to mandrel dimensions (e.g., 1mm mandrels: ~650).

Technical Specifications

System Compatibility

- Compatible with Steeger HS80/32 and below models.

- Supports Allen Bradley IMC4K and IMC7K machines.

Automation Details

- Fiber optic sensors for precise mandrel tracking.

- Pneumatic components with 1500 lbs. force at 80 PSI.

- Smart stepper motor for belt puller control.

- Modular upgrades for existing or new machines.

Performance

- Handles mandrels from 70cm to 2m in length.

- Supports a wide range of braid patterns, including full, half, and diamond.

- Accommodates triaxial configurations for specific applications.

© 2026 Steeger USA. All rights reserved. Designed and developed by: Tension Design