Bobbin Winders

Simple & Precision Bobbin Winders for Medical Manufacturing

Steeger USA’s bobbin winders prepares medical-grade thread or suture material for use in medical devices by winding it onto a specific bobbin format, ensuring consistent tension and proper delivery during operation. Steeger machines ensure precise and efficient winding and support the seamless operation of Steeger braiding machines, where required. Properly wound bobbins reduce downtime, minimize material waste, and improve product consistency. Whether you need simplicity or advanced precision, Steeger USA offers two reliable options to suit your production needs.

Why Choose Steeger Bobbin Winders?

- Improved Operational Efficiency: Reduces machine downtime and operator interventions.

- Consistent Results: Minimizes build failures and scrap material.

- Customizable Configurations: Tailored solutions to meet your material and process requirements.

Bobbin Winder Options

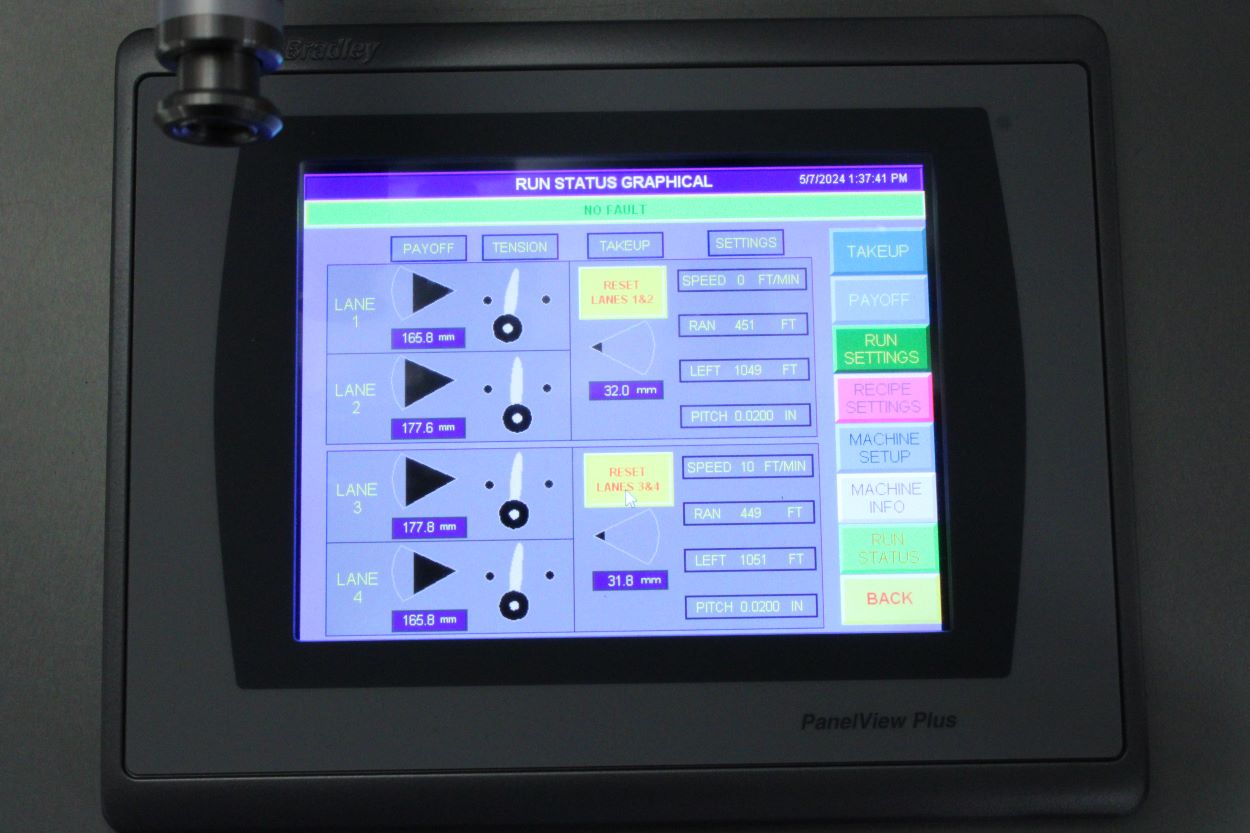

Simple Bobbin Winding Machine (SE)

The Simple Bobbin Winding Machine is ideal for basic in-house winding needs. It offers straightforward functionality with reliable performance for fiber applications.

Key Features:

- Single-lane (SWM-01), two-lane (SWM-02), and four-lane (SWM-04) configurations available (non-independent lane operation).

- Linear stroke: 100mm (Upgradeable to 145mm).

- Compatible with bobbin types: KL80d, KL4000, KL2002, NEB (with traverse upgrade).

- Bulk supply spool capacity: 8” diameter, 10” length.

- Suitable for most fiber applications; limited wire application support for 0.002”–0.006” OD range.

Technical Details:

- Allen Bradley PLC with recipe-driven HMI controls.

- Stepper motor-controlled linear actuator and take-up spindle.

- 4.3” HMI touch panel with mechanical fine adjustment for wire guides.

- External electronic tension control (10g to 500g range options).

- Break detection system.

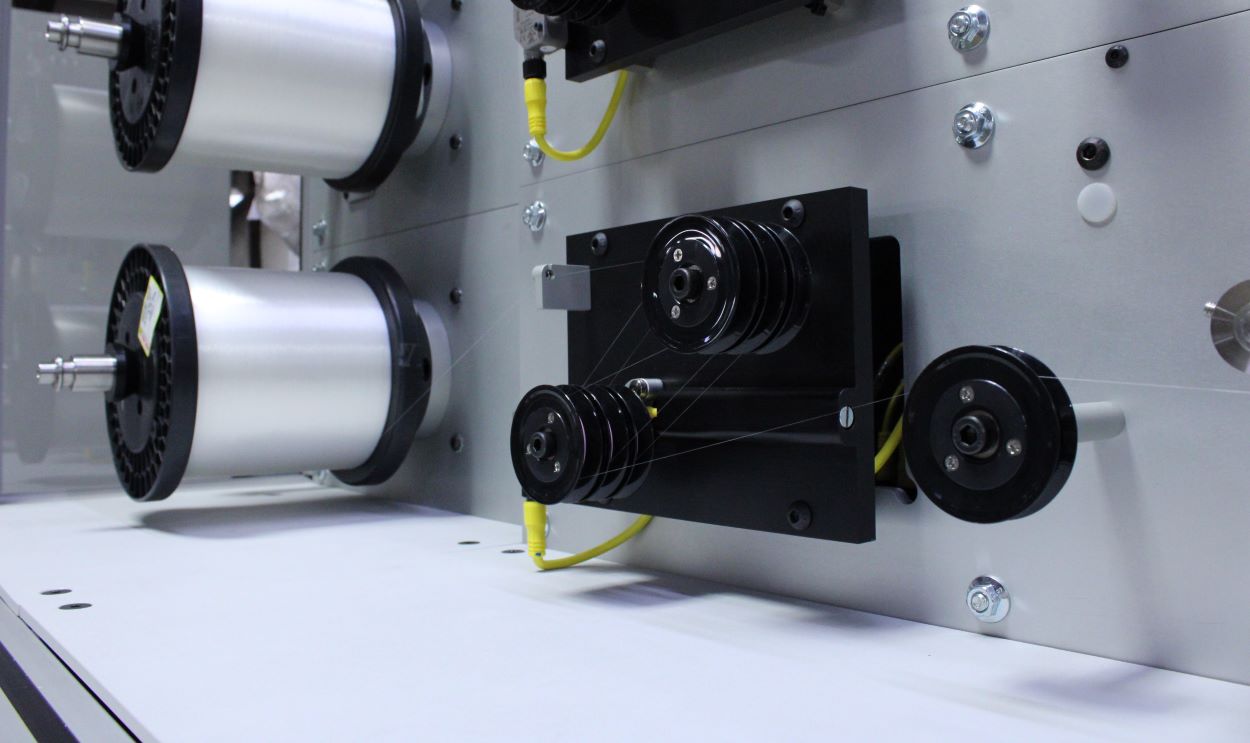

Precision Bobbin Winding Machine (IMC)

The Precision Bobbin Winding Machine delivers unmatched versatility for a broad range of materials, including fiber and wire. Designed for high-performance operations, it integrates advanced hardware and software for precision manufacturing.

Key Features:

- Single-lane (SWM-001), dual-lane (SWM-002), and quad-lane (SWM-004) configurations available (paired lane operation).

- Linear stroke: 145mm (Upgradeable).

- Compatible with bobbin types: KL80d, KL4000, KL2002, NEB.

- Bulk supply spool capacity: 8” diameter, 8” length.

- Fiber size range: 10d to 1100d.

- Wire size range: 0.0005”–0.010”.

Technical Details:

- Allen Bradley Safety PLC with 7” HMI touch panel.

- Servo motor-controlled payoff, traverse, and take-up spindles.

- Laser measurement for spool diameter tracking.

- Adjustable spring tension system with compression feedback.

- Tension ranges: 10g to 350g.

- High/low compression detection setpoints.