Braiding Machine In-line Heater Upgrade

Heating Element Integration for Braiding Systems

Steeger USA specializes in integrating advanced heating elements into braiding systems to optimize performance and improve product quality. Depending on your application, our heating solutions offer flexibility and precision, using either radiant heat or regulated hot air to meet your specific manufacturing needs.

Applications of Heating Elements in Braiding Systems

- Radiant Heat for Pre-Braiding Applications

- Radiant heat is applied to the core or mandrel before the braiding process begins.

- Pre-heating the core/mandrel improves material pliability, ensuring smoother and more uniform braiding.

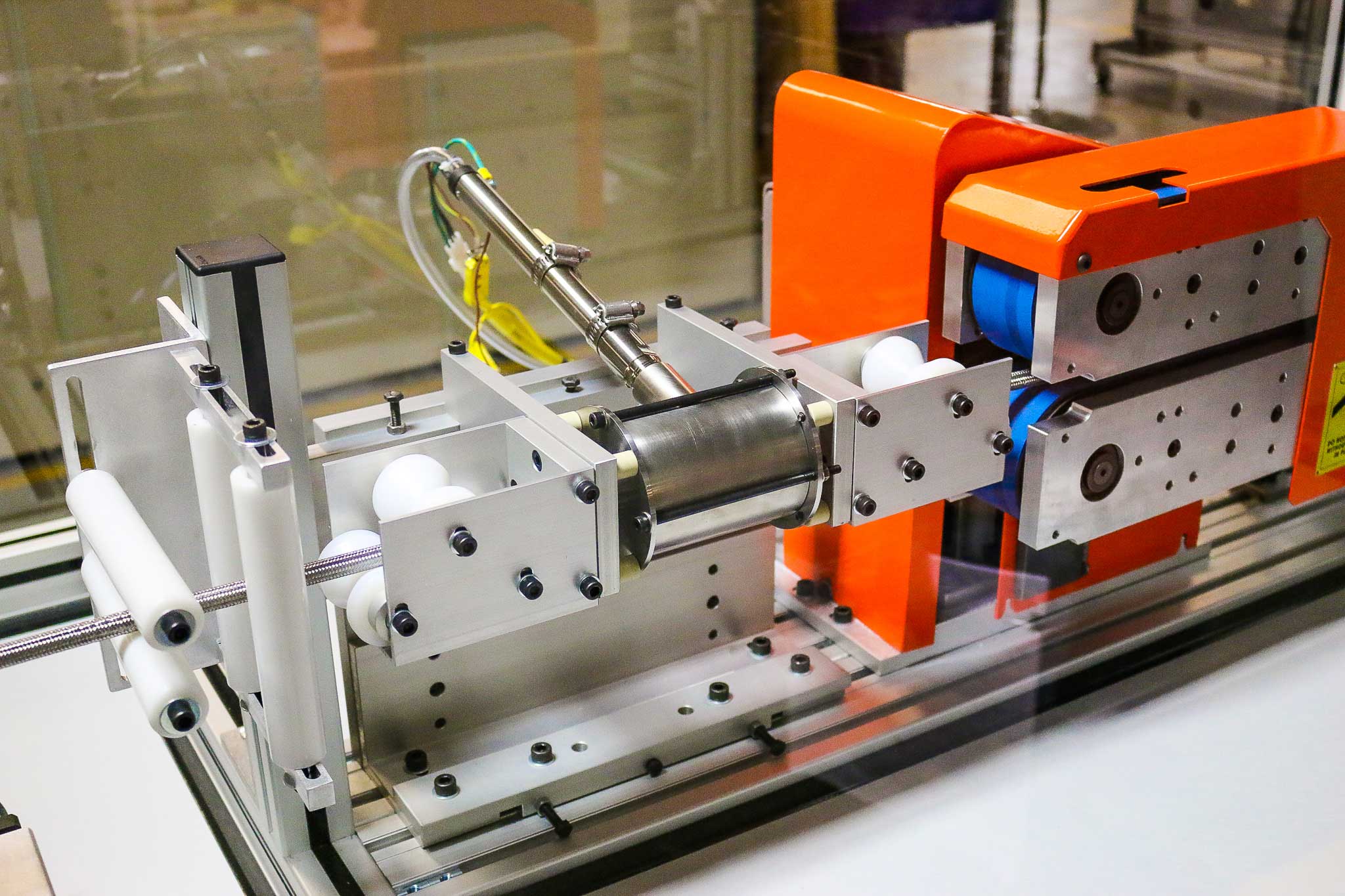

- In-Line Hot Air for Post-Braiding Applications

- Regulated hot air is applied after the braid has been laid onto the core or mandrel.

- This process softens the core/mandrel material, making it more compliant and allowing the braid to imbed into the product for enhanced performance.

Additional Heating Applications for Specialized Needs

- Polymer Fiber Braiding:

- Heat is used to bond braided polymer fibers, improving torque ability and strength.

- This results in a more durable and high-performing final product.

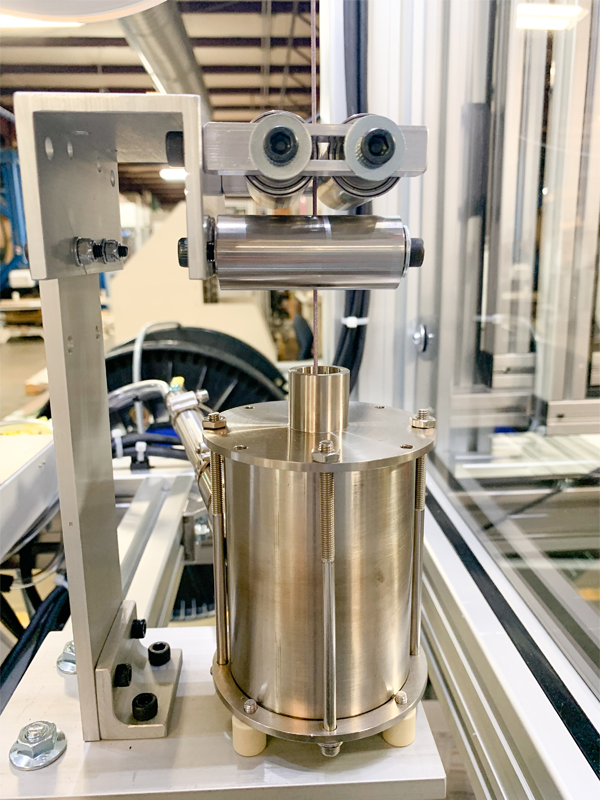

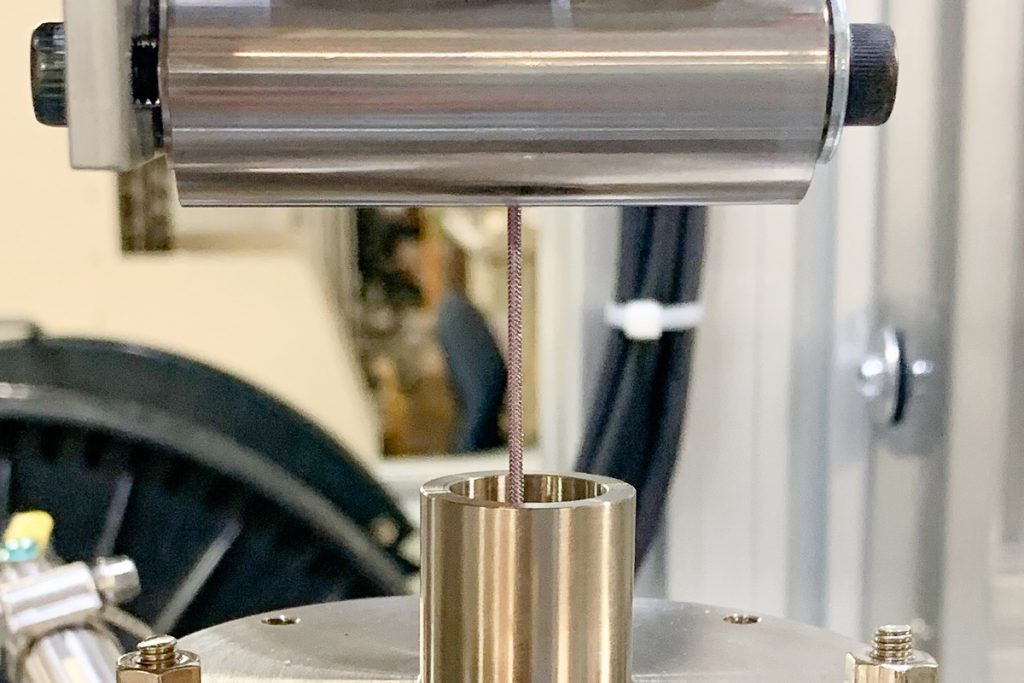

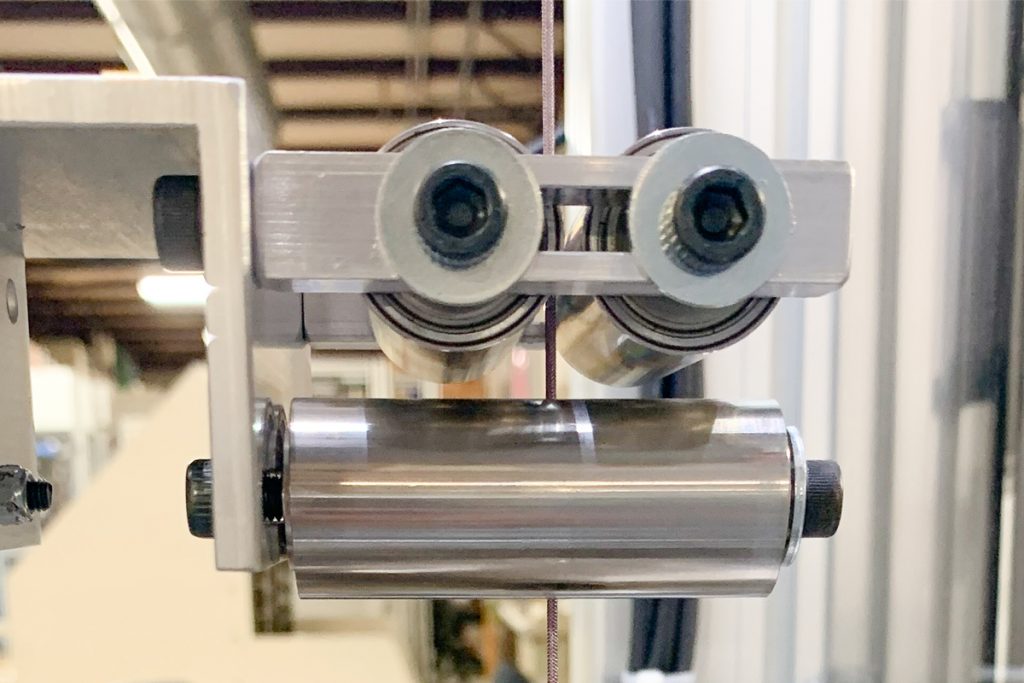

- Heated Center Tube or Cone:

- A heated tube or cone is used to warm the braid material as it forms onto the core material.

- This ensures precise material placement and consistent product quality.

Benefits of Integrated Heating Elements

- Improved Material Compliance: Heating softens materials, allowing better braid integration and embedding.

- Enhanced Product Strength: Bonding fibers during the process increases torque capability and overall durability.

- Custom Solutions: Tailored heating element configurations ensure optimal performance for your specific applications.

© 2025 Steeger USA. All rights reserved. Designed and developed by: Tension Design