Composite Braiding Systems

Advanced Solutions with the K80 Series Braiders

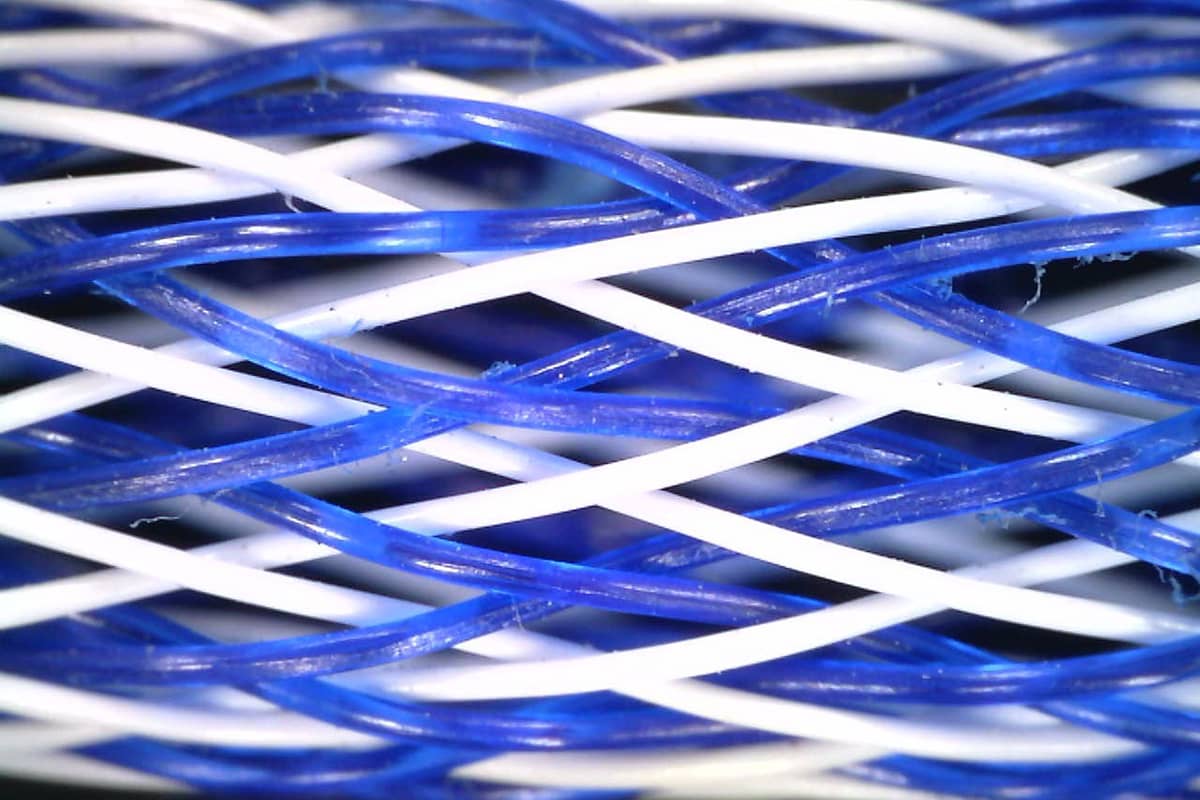

Steeger USA specializes in delivering composite braiding systems, powered by our cutting-edge K80 series horizontal and vertical braiders. These systems are designed for precision, reliability, and versatility, making them ideal for producing high-strength composite materials used in demanding industries like aerospace, automotive, and renewable energy.

Why Choose Composite Braiding Systems with the K80 Series?

Our composite braiding systems, built around the K80 series horizontal and vertical braiders, offer unparalleled performance to meet your advanced manufacturing needs. Key advantages include:

- Unmatched Precision: Achieve consistent and uniform braiding with the advanced tension control of the K80 series.

- Flexibility in Design: The K80 series supports diverse braid configurations, including round, flat, and complex patterns.

- Robust and Reliable: Engineered for demanding production environments with durable components and reliable operation.

- Material Versatility: Seamlessly process carbon fiber, glass fiber, aramid, and other high-performance materials.

Key Features of the K80 Series

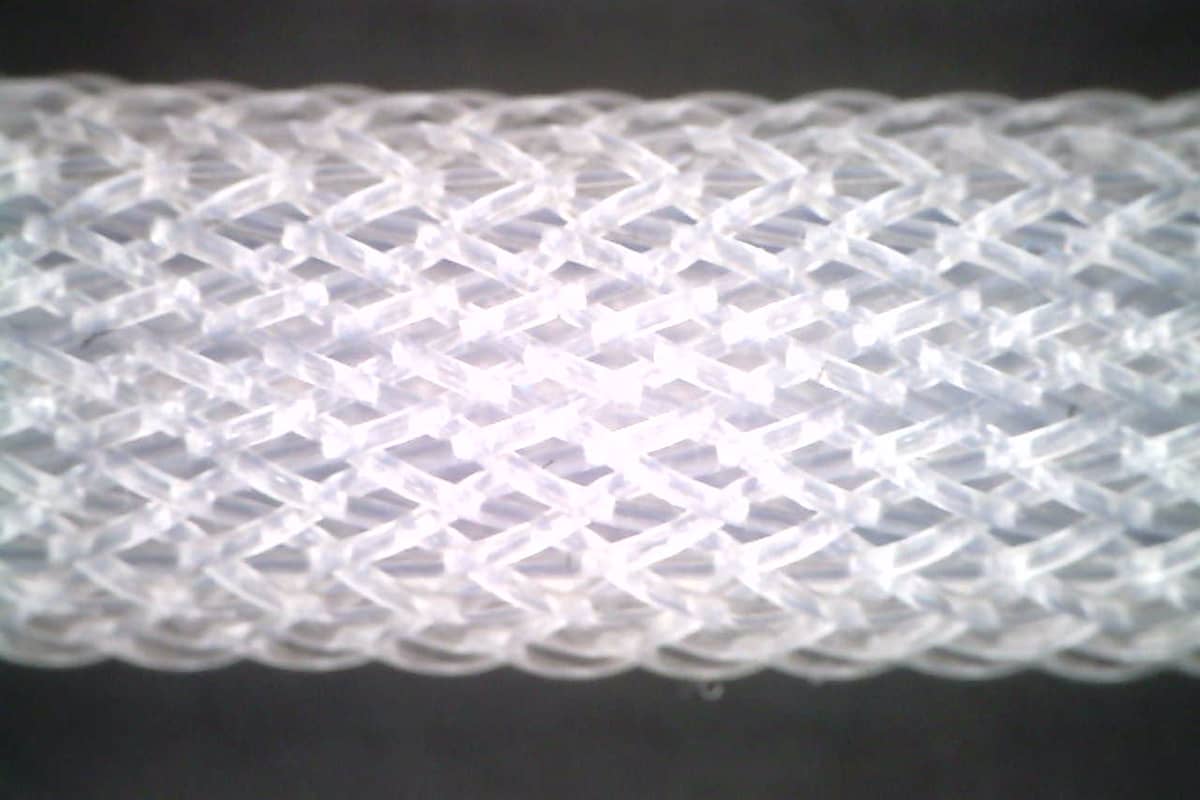

- Precision Engineering: The K80 series horizontal and vertical braiders ensure consistent tension and braid quality for composite structures.

- Customizable Configurations: Create round, flat, or intricate braids with fully adjustable parameters to meet your unique production requirements.

- User-Friendly Operation: Equipped with an intuitive HMI (Human-Machine Interface) for simplified setup, monitoring, and adjustments.

- Material Compatibility: Designed to handle a variety of composite materials, including lightweight and high-strength fibers.

- High Efficiency: Optimize throughput while maintaining precision and minimizing material waste.

Potential Applications of Composite Braiding Systems

Steeger USA’s composite braiding systems, featuring the K80 series braiders, are ideal for manufacturing high-performance composite materials used in:

- Aerospace Components: Lightweight, durable composite structures for critical aircraft systems.

- Automotive Manufacturing: Reinforced components such as shafts, frames, and energy absorption parts.

- Renewable Energy: Blades and structural components for wind turbines and other energy solutions.

- Sports and Performance Equipment: Lightweight and strong materials for bicycles, racquets, and protective gear.

- Industrial Applications: Durable braided composites for pipes, cables, and structural reinforcements.

Braiders with individual drive

Special braiding machines in horizontal design suitable for composite industry using special yarns and roving e.g. glass roving, ceramic yarns, glass and carbon roving, aramids and various other high tech yarns.

Individually driven braiders for manufacturing of:

- Maritime purposes: Multipurpose ropes and cards.

- Leisure sporting articles: Sport boat ropes, all kind spiral ropes, mountain climbing and static safety ropes, elastic ropes made out of composite yarns (e.g. tennis-rackets)

- Aviation: Parachute lines and elastic catapulting ropes.

- Automotive industry: Towing ropes and hydraulic hoses.

- Electro-technical purposes: Glass fibre or chemical linings.

- Braids and laces for the apparel, home furnishing and ornamental industry.

- – also machines with reversing carries –

These are heavy duty braiders used in the medical wire and composite industry. These braiders are available in vertical, horizontal or inverted design.

Technical services and spare parts available from Spartanburg, South Carolina.