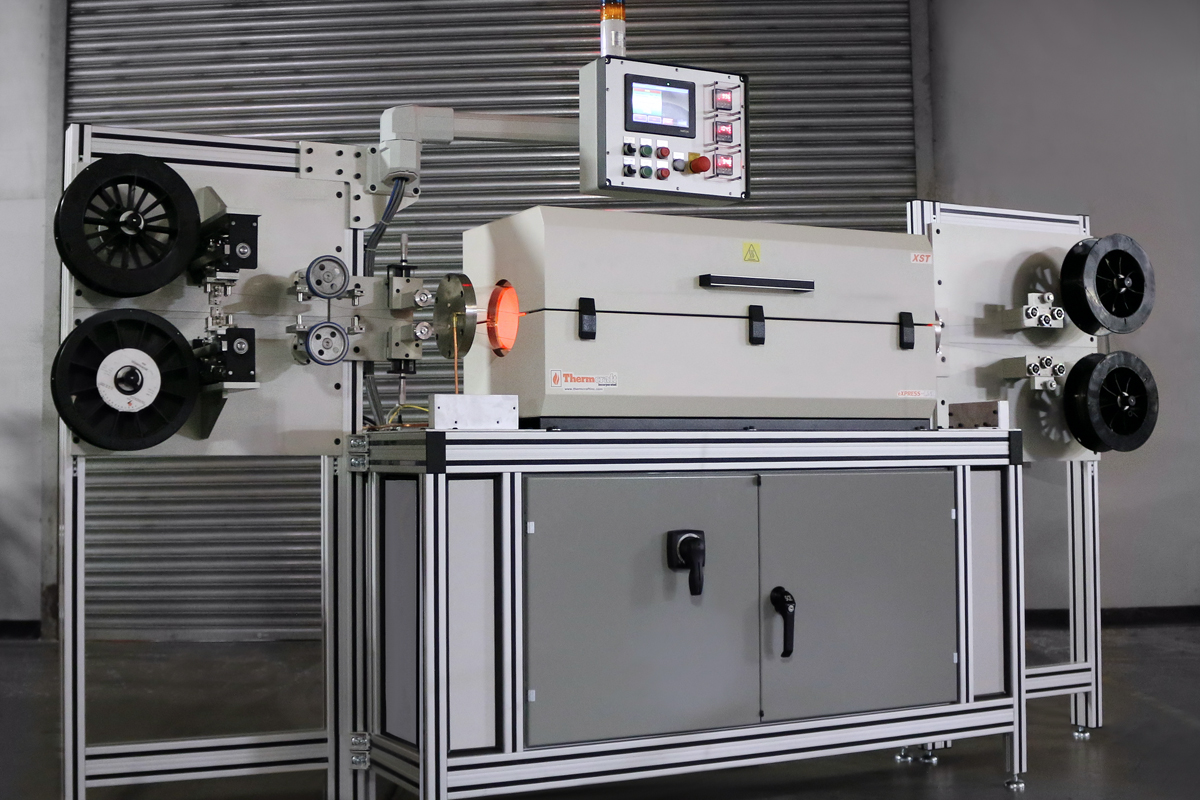

Reel to Reel Annealing Oven

Precision Annealing Oven with Reel-to-Reel Processing

Steeger USA offers a state-of-the-art annealing oven specifically designed for the continuous processing of Nitinol and other high-temperature metals. With advanced reel-to-reel capabilities, this system ensures efficient and precise annealing for demanding applications.

Key Features of the Annealing Oven

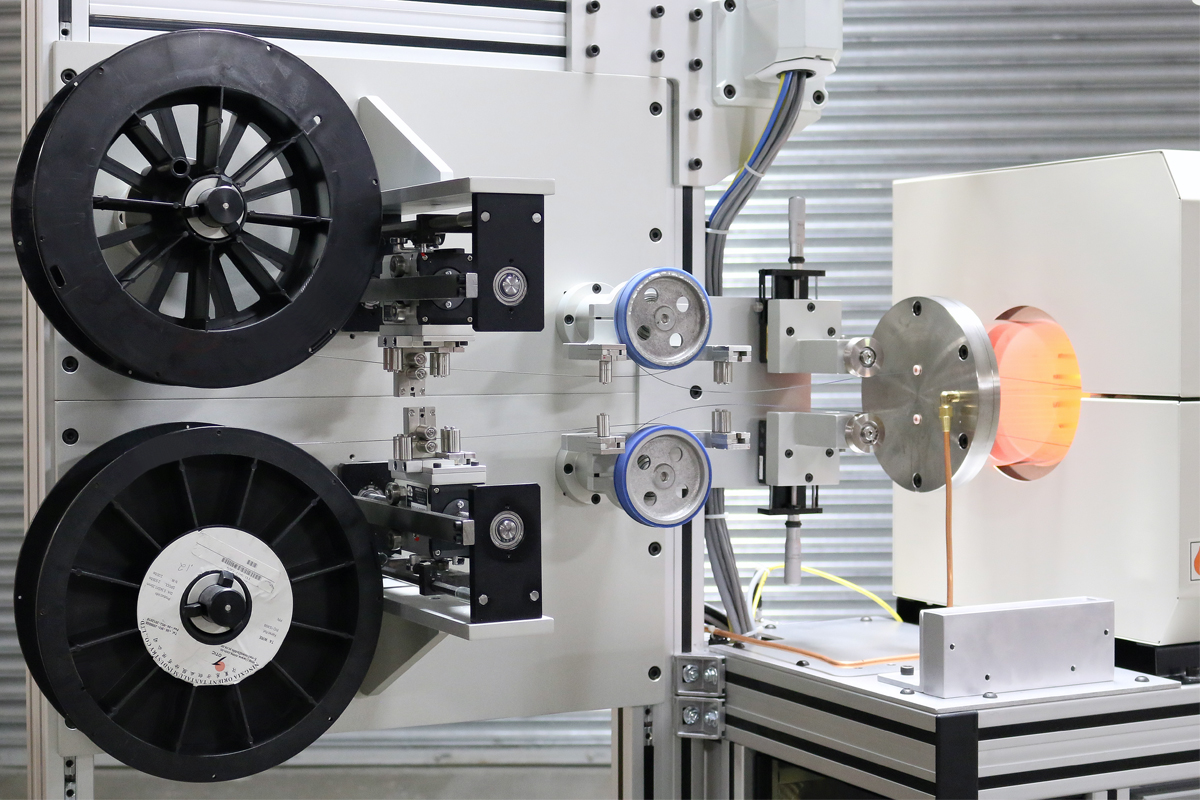

- Reel-to-Reel Annealing Process:

- Completed reels of braided material are loaded onto the machine and processed continuously.

- Materials are pulled smoothly through the annealing chamber, ensuring consistent results from start to finish.

- Ideal for high-volume production, minimizing downtime and maximizing throughput.

- Thermcraft Furnace for Uniform Heating:

Materials are advanced through a high-precision Thermcraft furnace, providing consistent and uniform annealing to maintain the integrity of Nitinol and other high-temperature metals. - Controlled Argon Environment:

The oven operates in a 99% Argon environment, using Festo valves and controllers to prevent oxidation and ensure a clean, high-quality finish. - Advanced Material Handling Technology:

- Yaskawa Servo Motors and Drives: Enable smooth, precise pulling of materials through the oven.

- RedLion HMI/PLC Controls: Offer real-time monitoring and adjustments for consistent annealing parameters.

- Tension Control for Accuracy:

Inline tensiometers regulate tension throughout the reel-to-reel process, creating a continuous feedback loop to avoid material distortion or inconsistencies.

Benefits of Reel-to-Reel Annealing Ovens

- High Efficiency: Seamless reel-to-reel operation minimizes manual intervention and production delays.

- Superior Quality: Uniform heating and precise tension control result in consistently annealed materials.

- Scalable Production: Supports large-scale manufacturing needs while maintaining precision.

The machine features a Thermcraft Express Line Split Tube Furnace capable of heating up to 1200°C. https://thermcraftinc.com/product-category/express-line-laboratory-furnaces/

For Service and Support

Call (864) 472-7000 or Email service@machinesolutionshost.com

© 2026 Steeger USA. All rights reserved. Designed and developed by: Tension Design