Taymer Visual Inspection System Add-on

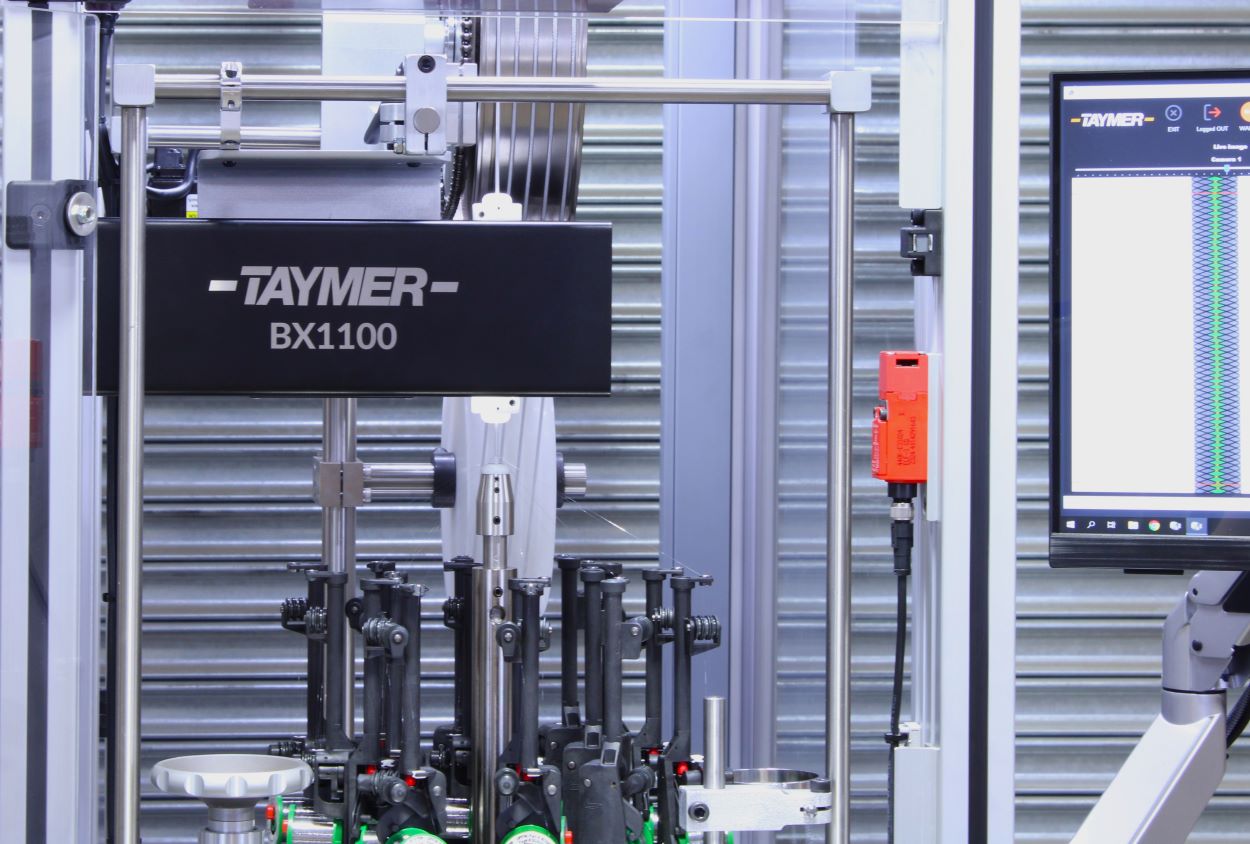

Taymer BX1100 Visual Inspection System Integration with Steeger USA Braiders

In collaboration with Taymer International, Steeger USA offers the Taymer BX1100 Visual Inspection System as a fully integrated solution for advanced quality assurance in horizontal and vertical braiding machines. This cutting-edge system provides real-time monitoring and defect detection, enhancing your production line’s efficiency and precision.

Standard Features of the Taymer BX1100 Visual Inspection System

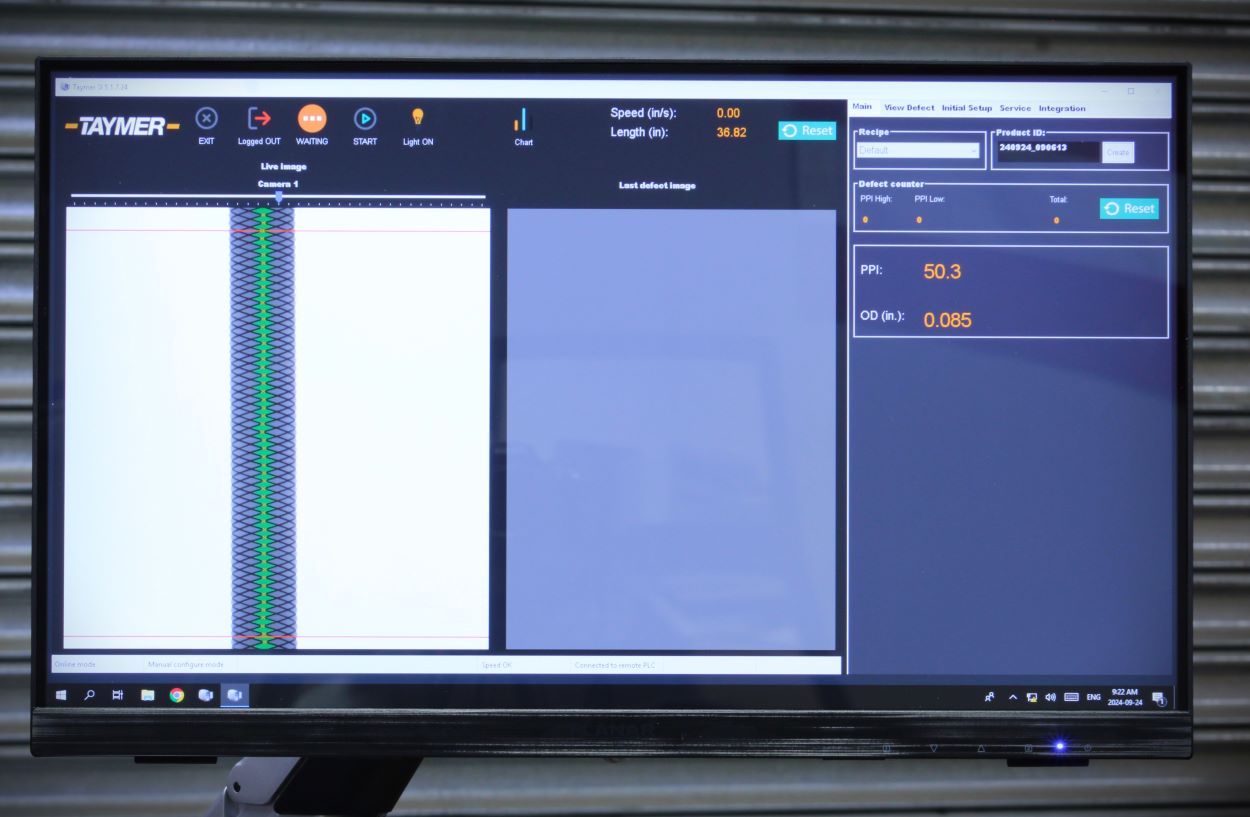

- Comprehensive Monitoring: Inline measurement of PPI and OD for full product length inspection.

- Integrated Hardware: Includes a high-speed digital camera, protective housing, and industrial-grade PC with a 22” touchscreen for real-time control and monitoring.

- Data Logging and Reporting: Automatically generates batch reports and logs detailed machine data for production analysis.

- Seamless Steeger Integration: Compatible with SE and IMC braiders for streamlined operation with start/stop control via PLC input.

Performance Highlights

- PPI Range: 10–100 PPI (±2–4 PPI)

- OD Range: 0.050″–0.5″ (±0.004″)

- Material Compatibility: Reflective, non-reflective, and translucent braid materials.

Optional Upgrades

- High-Precision Inspection: Extend the PPI range to 5–250 (±2) and OD measurement tolerances to ±0.002″ for more detailed monitoring.

- Advanced Defect Detection: Identify flipped wires, broken strands, or asymmetrical braids with enhanced image processing.

- Custom Lighting Solutions: Improve inspection accuracy for challenging materials with specialized lighting options.

Potential Applications of the Taymer BX1100 Visual Inspection System

- Medical Devices: Maintain consistent quality for catheter braiding, guidewires, and other precision devices.

- Aerospace Manufacturing: Ensure high-strength, lightweight braided components meet stringent industry standards.

- Telecommunications: Monitor braided cables and shielded wires for signal integrity and durability.

- Automotive: Optimize the quality of wiring harnesses and reinforced braided cables.

- Industrial Applications: Inspect heavy-duty braided hoses, ropes, and cables for uniformity and reliability.

Partnering with Taymer International

The Taymer BX1100 represents the latest innovation in visual inspection technology. By integrating this advanced system with Steeger USA’s braiding machines, manufacturers gain access to superior quality assurance tools backed by decades of engineering expertise from both Steeger USA and Taymer International. Learn more at www.taymer.com.

© 2025 Steeger USA. All rights reserved. Designed and developed by: Tension Design