Textile and Harness Braiding Machines

Textile and Harness Braiding Machines: Precision Solutions for Diverse Applications

Steeger USA specializes in designing and manufacturing textile and harness braiding machines tailored to meet the demands of modern manufacturing. Our state-of-the-art machines provide the precision, durability, and versatility needed to produce high-quality braided products for textiles, automotive harnesses, and industrial applications.

Key Features of Textile and Harness Braiding Machines

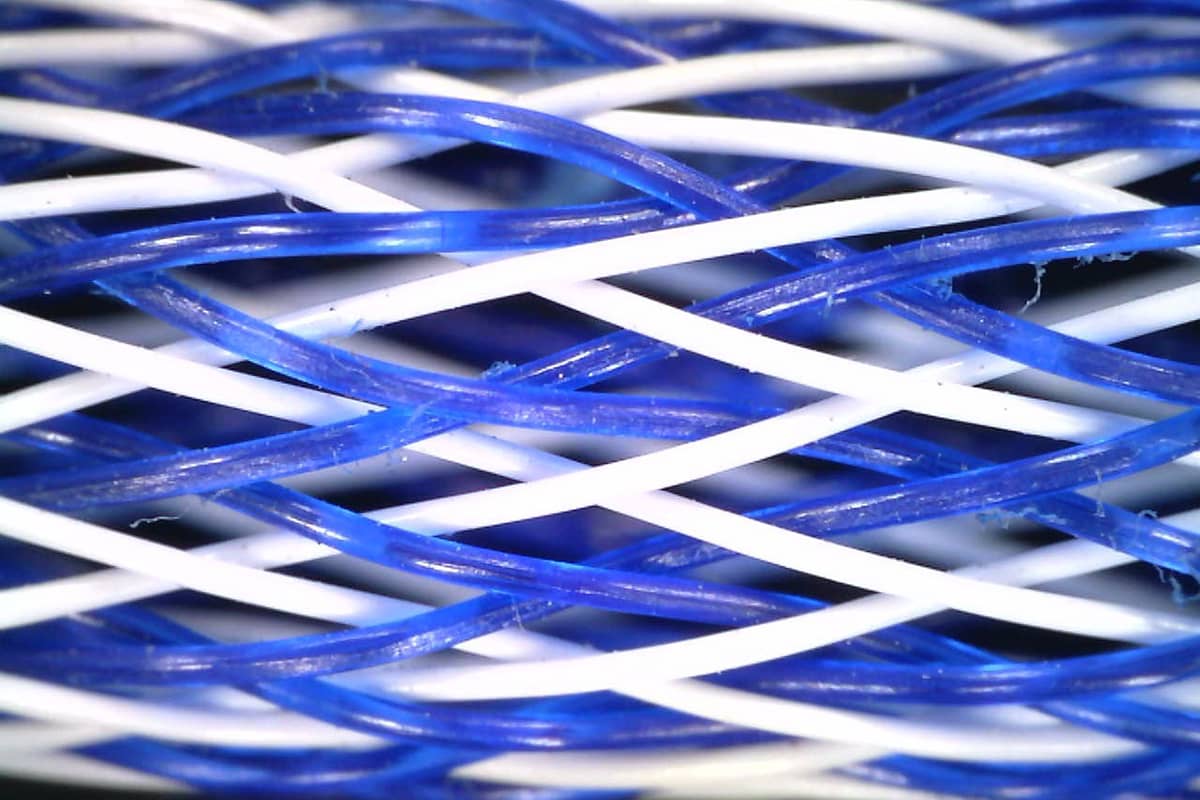

- Precision Braiding Technology: Ensure uniform tension control for consistent braid quality and strength.

- Versatile Configurations: Create round, flat, and complex braid patterns for diverse applications.

- Customizable Settings: Adjustable speed, carrier tension, and braiding angles to meet unique production requirements.

- User-Friendly Operation: Intuitive HMI (Human-Machine Interface) for easy programming, monitoring, and adjustments.

- Durable Construction: Designed to handle high-volume production with minimal downtime.

Potential Applications

Steeger USA’s braiding machines are ideal for producing high-quality braids in:

- Textile Manufacturing: Braided materials for clothing, home furnishings, and technical textiles.

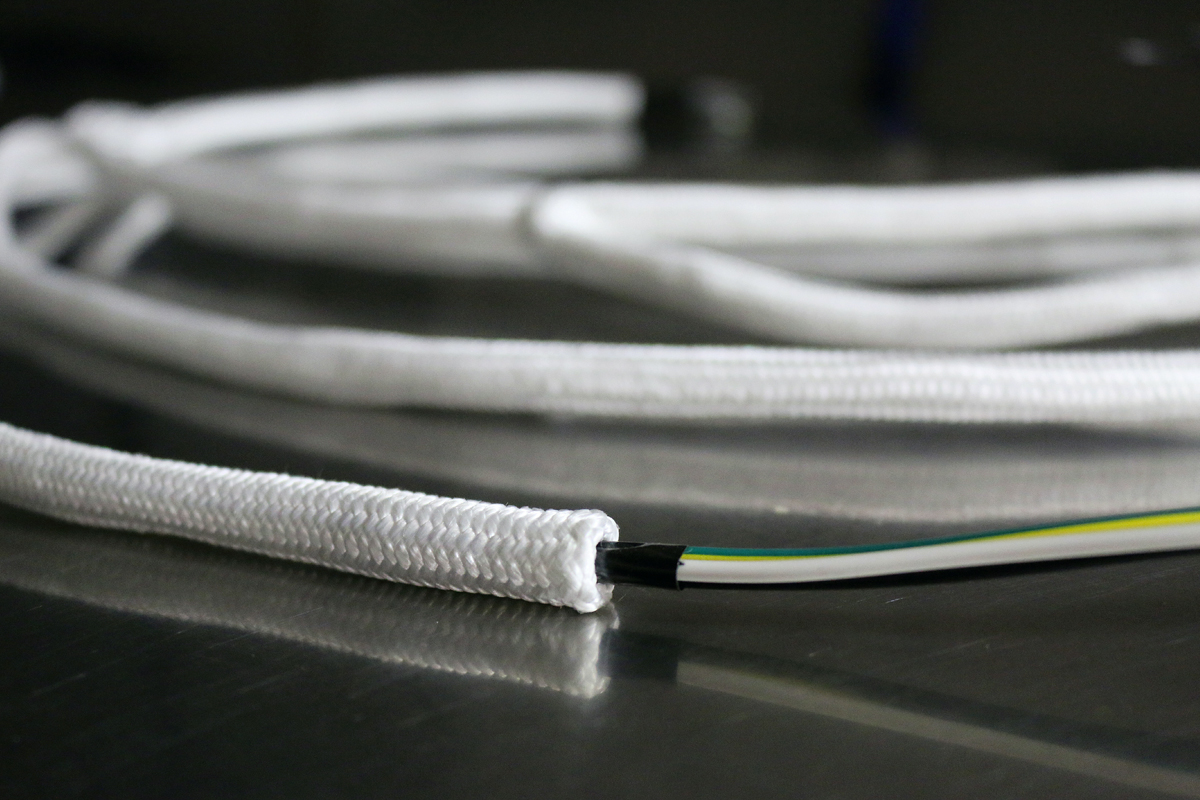

- Automotive Harnesses: Durable and flexible braids for vehicle wiring harnesses and protective sleeves.

- Aerospace Applications: Lightweight and strong braided materials for wiring and structural reinforcements.

- Industrial Uses: Braided ropes, cables, and protective coverings for heavy-duty applications.

- Consumer Products: Braided materials for shoelaces, straps, and other everyday products.

Benefits of Steeger USA’s Textile and Harness Braiding Machines

- Enhanced Efficiency: Maximize production speeds without sacrificing quality.

- Reliable Quality Control: Advanced tension systems ensure consistent braiding results.

- Cost Savings: Reduce material waste and downtime with efficient, durable equipment.

- Tailored Solutions: Adaptable machines to fit your specific production goals and requirements.

Spec. Sheet Download

© 2026 Steeger USA. All rights reserved. Designed and developed by: Tension Design