32 to 16 Modular System

Maximizing Efficiency for Your Braiding Machine

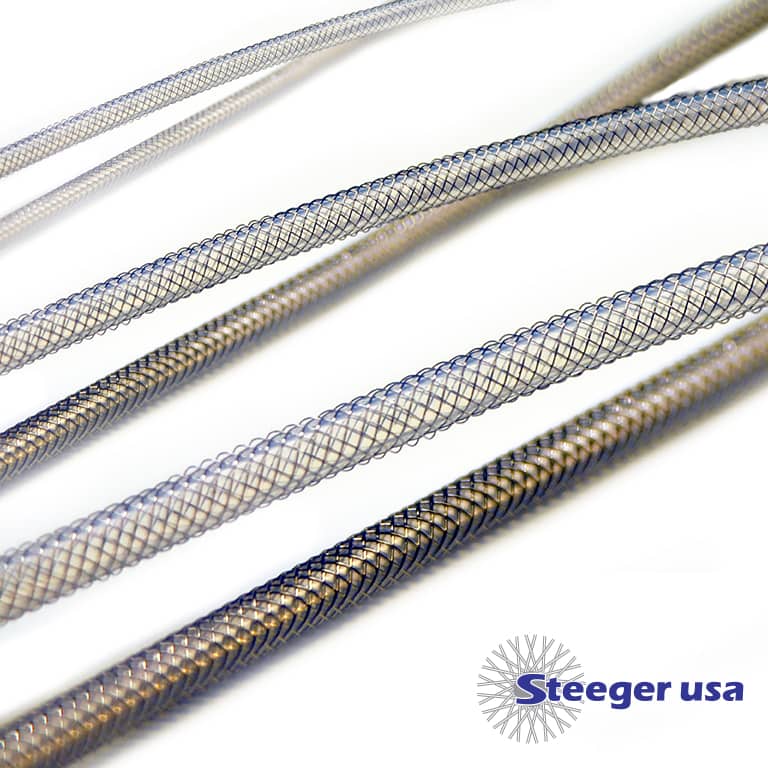

Steeger USA offers a 32-to-16 Carrier Upgrade for customers seeking to optimize their braiding machines for smaller-scale production runs and enhanced precision. This upgrade is a cost-effective solution for manufacturers who no longer require the capacity of a 32-carrier machine but want to maintain the versatility and quality of their equipment.

The Story Behind the 32-to-16 Carrier Upgrade

Steeger USA’s engineering team developed this upgrade in response to a growing demand for smaller, more efficient braiding configurations. Many of our customers realized that their production processes didn’t always require the output of a 32-carrier machine. Instead of replacing their existing equipment, they needed a smart solution that preserved the functionality of their current system while adapting to changing production needs.

The 32-to-16 Carrier Upgrade allows manufacturers to maintain operational efficiency without the significant investment in new equipment. By converting to a 16-carrier setup, customers gain the ability to tackle smaller production runs with improved precision and reduced waste.

Why Make the 32-to-16 Carrier Upgrade?

This upgrade offers several advantages for manufacturers seeking flexibility and efficiency in their braiding operations:

- Cost-Effective Solution:

- Avoid the expense of purchasing a new braiding machine.

- Extend the life of your existing equipment with a tailored upgrade.

- Enhanced Precision:

- The reduced carrier count allows for more precise braiding, ideal for smaller-scale applications.

- Versatility:

- Retain the ability to switch between different braiding configurations, supporting a variety of products and materials.

- Reduced Waste:

- Smaller production runs minimize material waste, helping reduce operational costs.

How the Upgrade Works

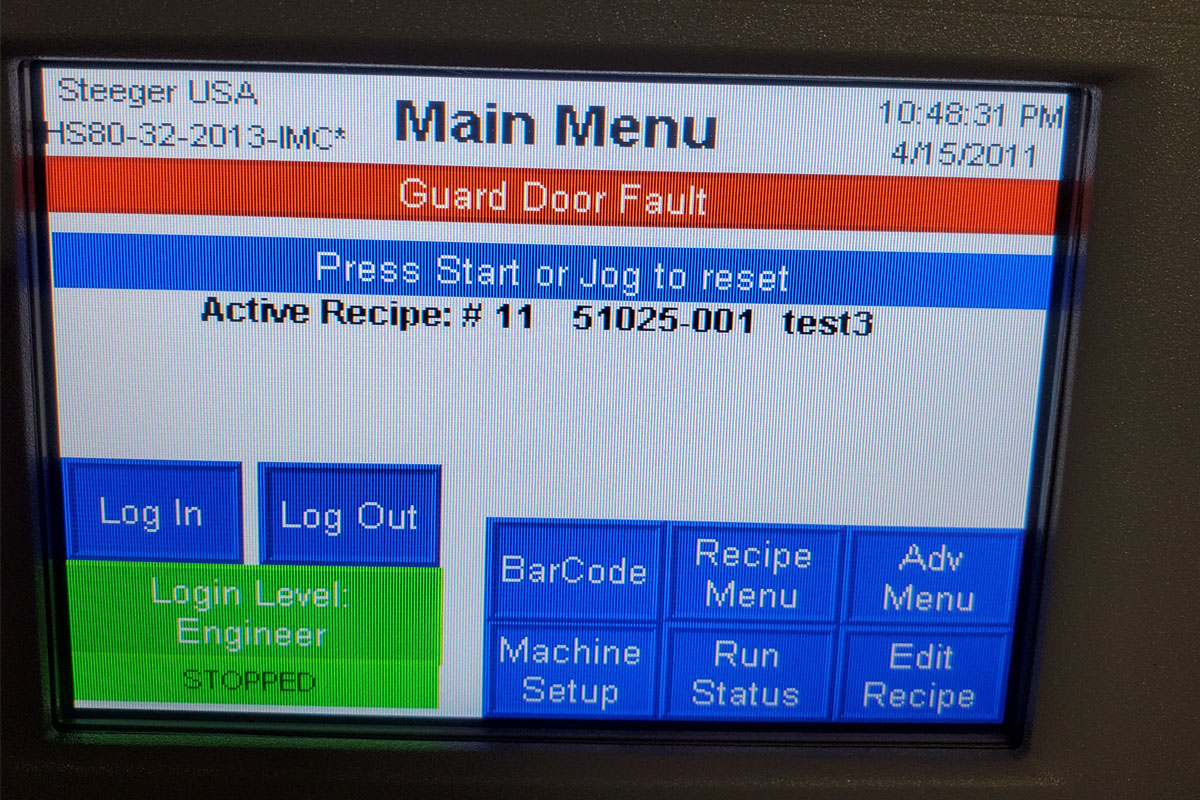

- Assessment and Planning:

- Steeger USA evaluates your current 32-carrier machine and production requirements.

- Our engineering team designs a custom conversion plan to fit your needs.

- Conversion Process:

- Carriers and machine components are reconfigured to support a 16-carrier setup.

- Adjustments are made to maintain the precision and functionality of the equipment.

- Testing and Validation:

- After the upgrade, the machine is thoroughly tested to ensure optimal performance and reliability.

- Ongoing Support:

- Our team provides training and guidance to help you maximize the benefits of your upgraded machine.