Coil Winder (Model SCW-01)

COMING SOON!

Purpose-Built Coil Winding for Advanced Catheter Designs

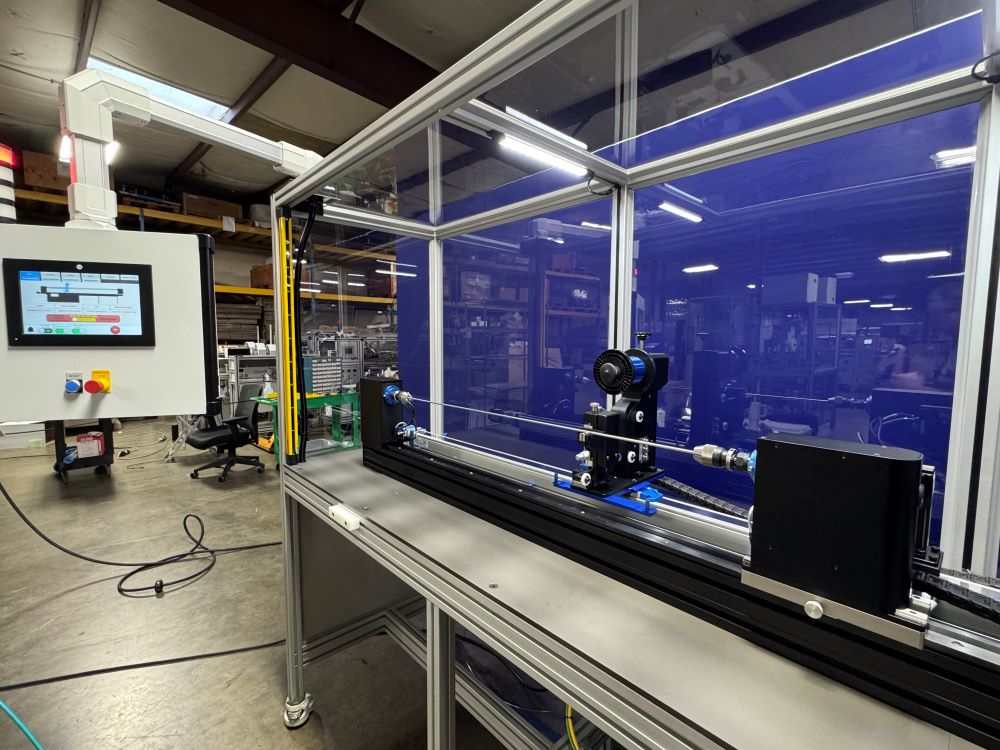

The Steeger SCW-01 Coil Winder is a dedicated system for producing precise, discreet coils for catheter and minimally invasive medical devices. Built by the leader in medical braiding and coiling equipment, the SCW-01 extends Steeger’s reputation for precision and reliability into a new generation of coil winding technology.

Instead of relying on adapted braider add-ons or legacy coiling platforms, manufacturers gain a purpose-built coiler that delivers stable tension, accurate pitch control, and repeatable geometry for demanding catheter shaft designs.

Why Choose the SCW-01 Coil Winder?

The STW-01 is designed specifically for medical device manufacturers who need:

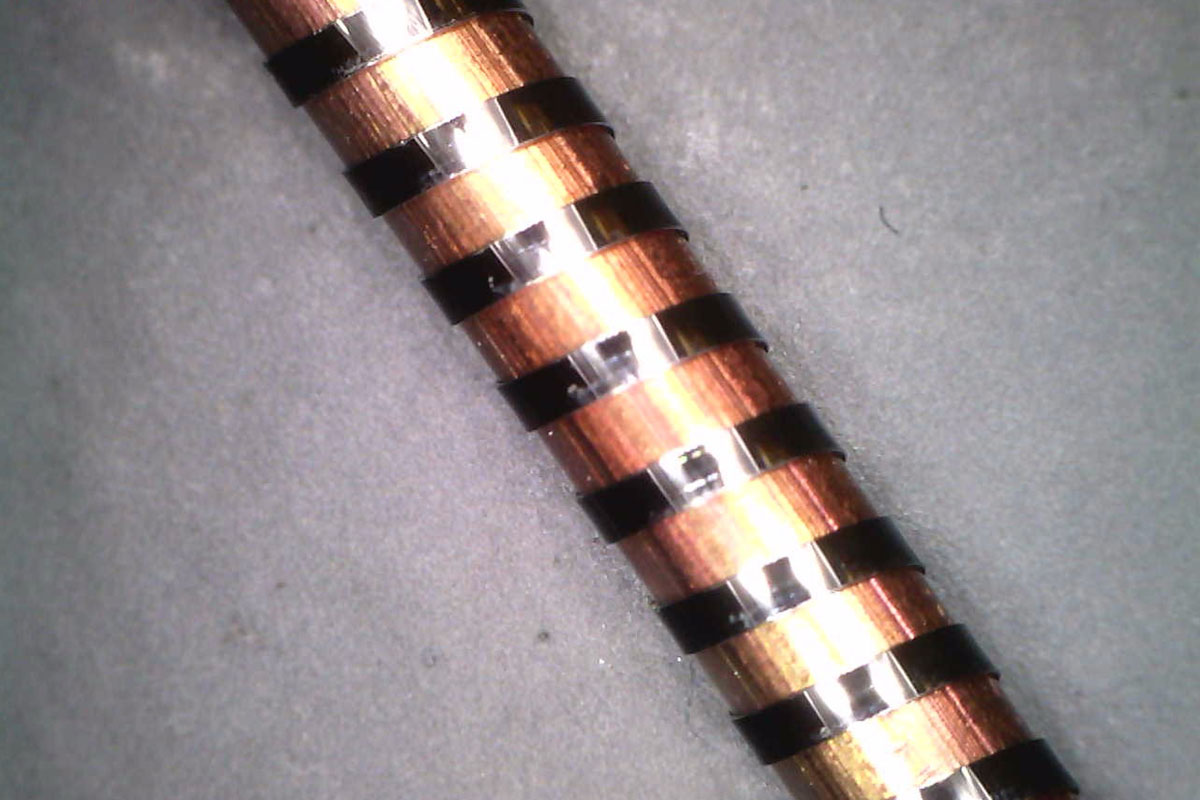

- Consistent coil geometry for reinforced catheter shafts

- Stable tension control across multiple coil segments

- A dedicated coiler that frees braiders for their primary applications

- An alternative to incumbent coil winding solutions with improved service and support

By pairing optimized payoff heads with multiple frame lengths and medical-grade spool compatibility, the STW-01 provides a flexible platform that supports both development work and full-scale production.

Key Features

Purpose-Built Discreet Coiler

Engineered specifically for catheter and minimally invasive device applications where coil reinforcement is critical to performance and handling.

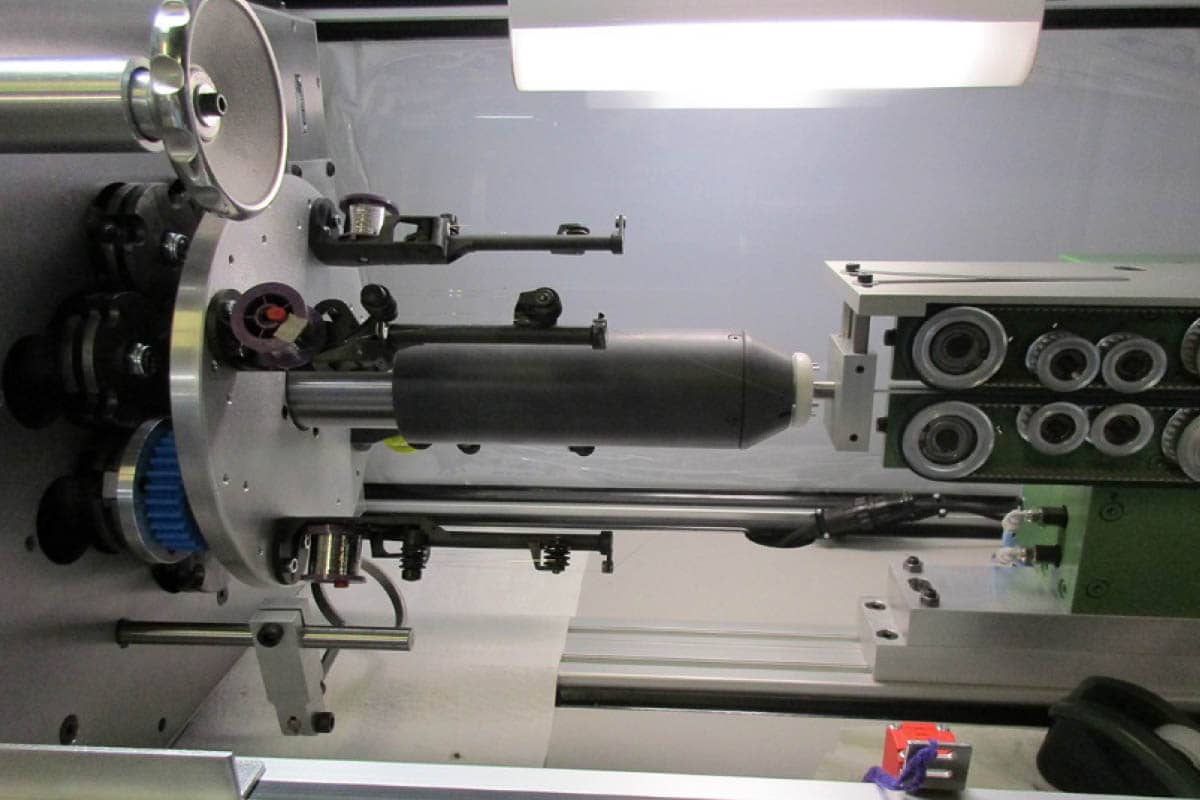

Three Payoff Head Options

Three distinct payoff head configurations allow users to match tension profiles to different wire sizes, materials, and coil designs.

Multiple Frame Lengths

Standard frame offerings support 36″, 48″, 72″, and 96″ mandrels, aligning with common catheter shaft lengths and manufacturing footprints.

Precise Pitch Control

Designed for accurate, repeatable pitch control, including multi-segment and variable-pitch coil structures.

Spool Compatibility

Supports widely used KL80D bobbins and Din100 spools to simplify integration into existing catheter manufacturing environments.

Steeger Engineering and Support

Backed by Steeger USA and the Machine Solutions family, with access to experienced engineering resources and responsive service teams.

Typical Applications

The SCW-01 Coil Winder is ideal for a wide range of medical device and catheter applications, including:

- Cardiovascular catheter shafts

- Structural heart delivery systems

- Neurovascular micro-catheters

- Electrophysiology and mapping catheters

- Guidewires and micro-assemblies

- Multi-segment coils for variable stiffness and kink resistance

Whether for R&D, process development, or production, the STW-01 provides the control and repeatability required for modern device designs

How the SCW-01 Improves Your Process

Improved Efficiency

A dedicated coiling platform shortens changeovers, reduces reliance on braider-based coiling, and helps maintain higher overall line availability.

Enhanced Consistency

Repeatable tension control and pitch accuracy help reduce scrap, minimize rework, and support more predictable process validation.

Flexible Configuration

Multiple payoff head options and frame lengths give engineers and manufacturing teams the freedom to support diverse coil designs without over-customizing equipment.

Validation-Friendly Operation

Stable, repeatable process parameters simplify validation and support documentation requirements for regulated medical device manufacturing.

Integration Options

The SCW-01 Coil Winder can be integrated into:

- Standalone coil winding cells

- Catheter shaft reinforcement lines alongside Steeger braiders and laminators

- Automated or semi-automated manufacturing cells within the Machine Solutions ecosystem

For customers already running Steeger braiders, the STW-01 provides a familiar process philosophy while separating coiling from braiding to maximize throughput and flexibility.