KPI Alert Tracking

Optimize Performance with Real-Time Monitoring

Steeger USA’s KPI Alert Tracking system is designed to help manufacturers monitor and optimize the performance of their braiding machines in real time. By tracking critical key performance indicators (KPIs), this innovative solution ensures operational efficiency, minimizes downtime, and supports consistent product quality.

How It Works

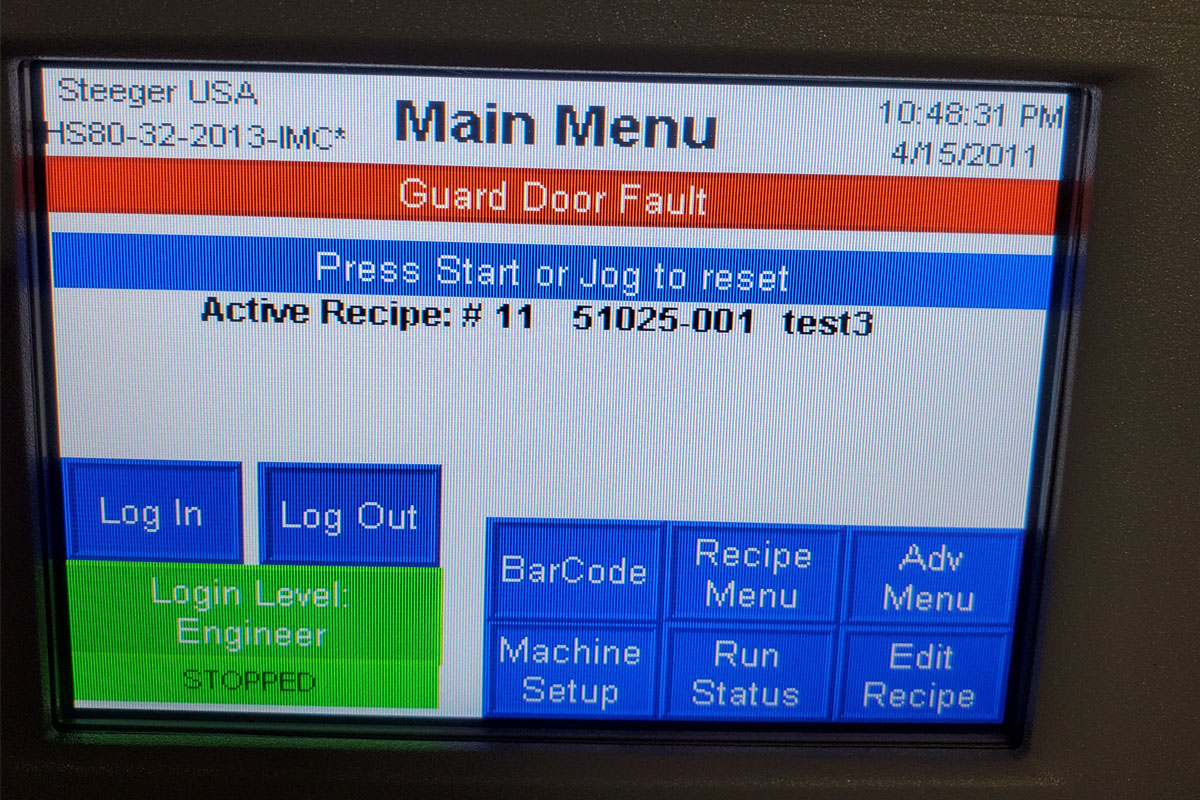

KPI alert tracking provides a real-time monitoring system that collects and analyzes performance data from your braiding machines. When a KPI falls outside of acceptable thresholds, the system sends an immediate alert to the operator, allowing quick corrective action to prevent production issues.

Why Use KPI Alert Tracking?

Adding KPI tracking to your braiding operations provides significant advantages, including:

- Improved Operational Efficiency:

- Monitor machine performance in real time to identify and address inefficiencies.

- Enhanced Quality Control:

- Ensure your braiding machines consistently meet production standards.

- Minimized Downtime:

- Receive immediate alerts to resolve issues before they cause costly interruptions.

- Data-Driven Decision Making:

- Access detailed performance data to improve operational strategies and outcomes.

Key Features of Steeger USA’s KPI Alert Tracking

- Real-Time Monitoring:

- Track KPIs such as production speed, tension control, and material usage with up-to-the-minute data.

- Customizable Alerts:

- Set specific thresholds for each KPI, ensuring you receive alerts tailored to your production needs.

- HMI Integration:

- View performance metrics and alerts directly on the braiding machine’s Human-Machine Interface (HMI) for easy access and control.

- Comprehensive Reporting:

- Generate detailed reports to analyze trends, identify bottlenecks, and improve overall efficiency.

© 2025 Steeger USA. All rights reserved. Designed and developed by: Tension Design