Medical Catheter Coiling Machine

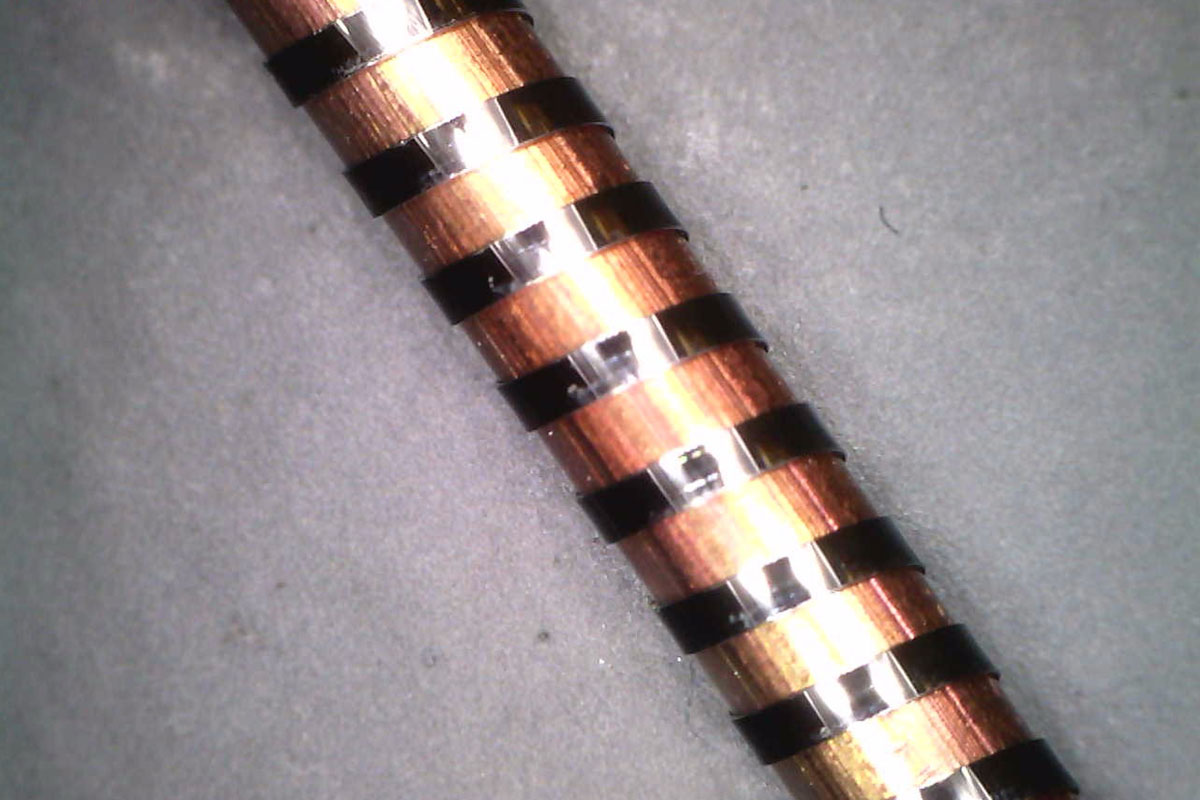

SteegerUSA catheter coiling machines are designed to coil any material between 0.0005” and 0.01” in diameter and flat materials from 0.0005”x 0.002” up to 0.003” x 0.008”. Catheter coiling machines can coil with a pitch from 1” down to +10% times the material diameter or width (flat wire).

Steeger USA has multiple configuration of catheter coiling machines to meet your needs:

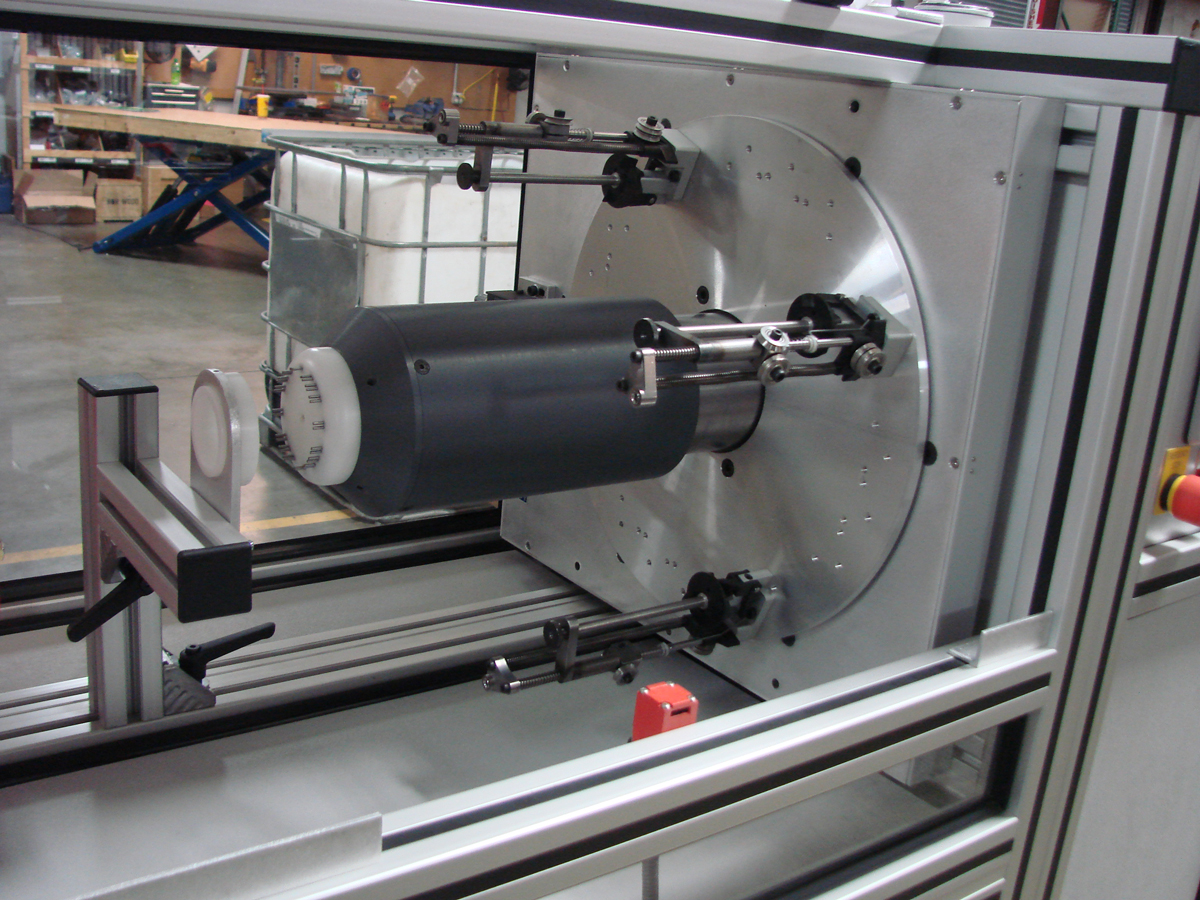

1. The Coiler Retrofit Kit- This Retrofit kit is designed to adding catheter coiling capabilities our 16-carrier braiding machines. This add-on retrofit can coil up to 12 carriers of material (12-Ends), onto a continuous core or discrete mandrels that range from 0.0005” to 0.2” in diameter. The Catheter Coiler Machine Retrofit Kit can be mounted on a 16-carrier vertical or horizontal braiding machine and will coil catheters at a maximum speed of 200 RPM. The is designed to work with all our IMC style Braiders.

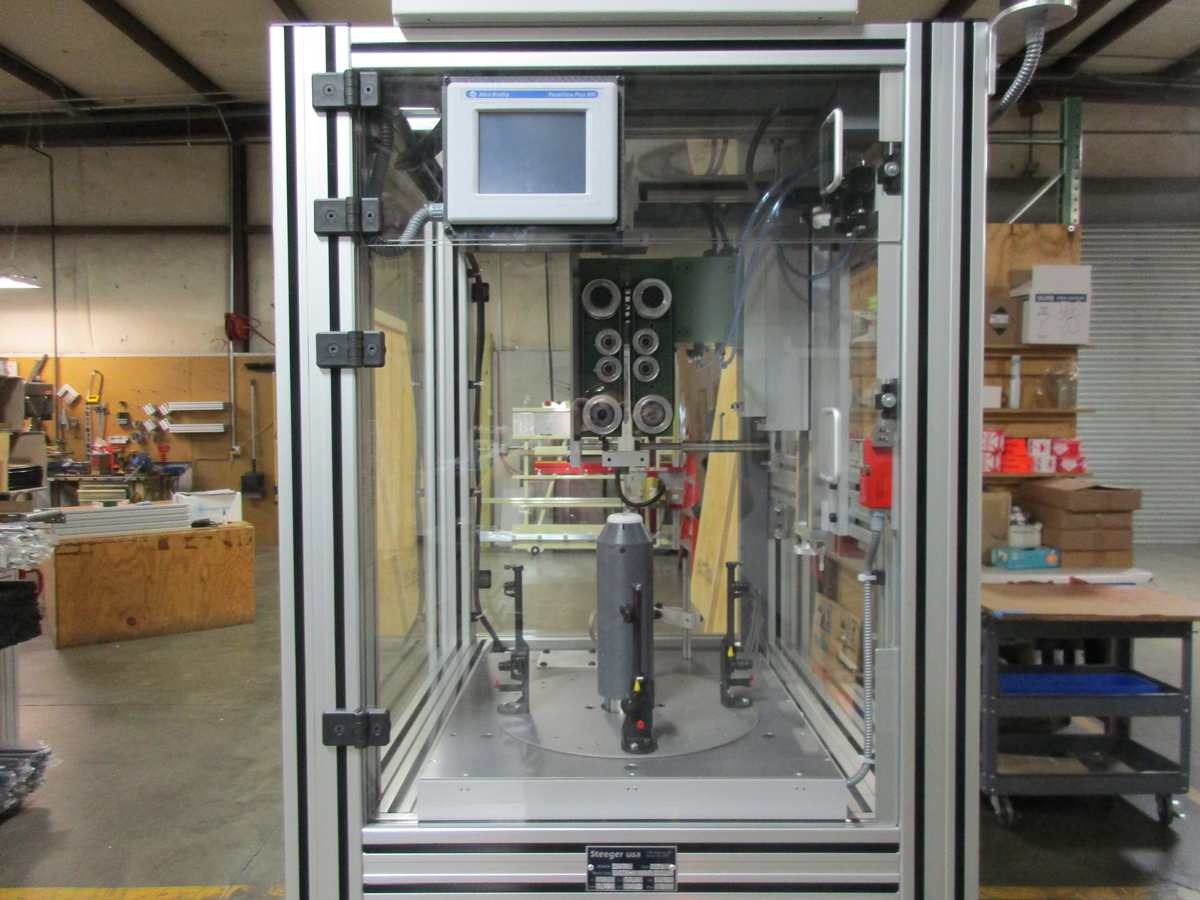

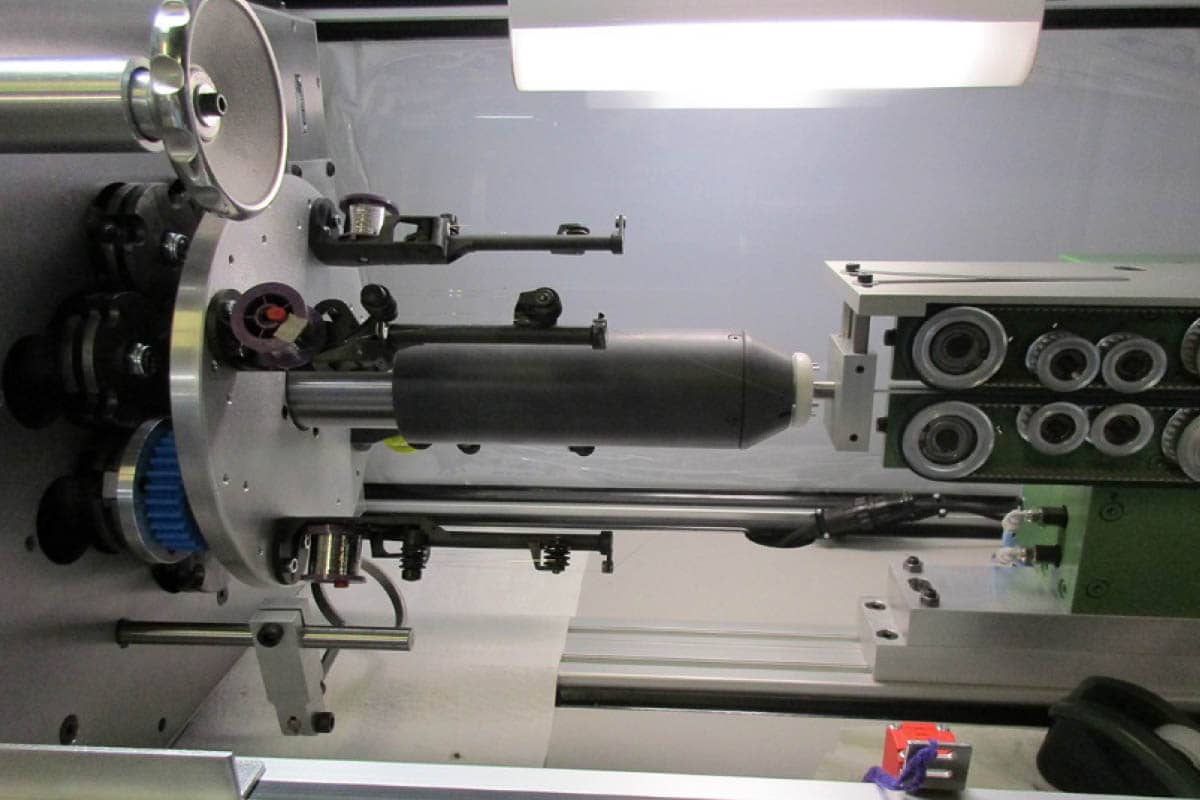

2. The Standard Catheter Coiling Machine- This designated catheter coiling machine can coil up to 16 carriers of material (16 Ends), onto a continuous core or discrete mandrels that range from 0.0005” to 0.3” in diameter. These coiling units can be built in a vertical or horizontal style. The maximum speed for this machine is 400 RPM.

3. The Heavy Catheter Coiling Machine- This designated catheter coiling machine can coil up to 24 carriers of material (24-Ends), onto a continuous core or discrete materials that range from 0.0005” to 2” in diameter. These catheter coiling machines can be built in a vertical or horizontal style. The maximum speed for this machine is 400 RPM.

4. The Heavy Single End Machine- This designated machine is great for coiling applications that use a flat ribbon wire. This machine is designed for single end use and for large quantity runs. The coiler can be upfitted with up to a DIN160 spool.

5. Dual Head Machines- Steeger USA has experience combining coiling and braiding machines to make Braider/Coiler, Coiler/Braider, Coiler/Coiler, and Braider/ Braider machines for multi-function applications. These systems are designed to run simultaneously, independently and variably as the operator requires. The machine has two heads that are in-line and servo driven. This allows for control of one, or both heads, at the same time. The machine can variable braid/coil, this means that the pitch and PPI can be programmed to change over the course of the product. This machine is also capable of running either the Coiler or Braider independently.

Our stranding equipment is designed in 3,4 & 7 configurations ideal for medical wore, electrical and other wire stranding applications.