Braider Control System Upgrade

Upgrade Your Braiding Machine with Steeger USA’s Advanced Braider Control System

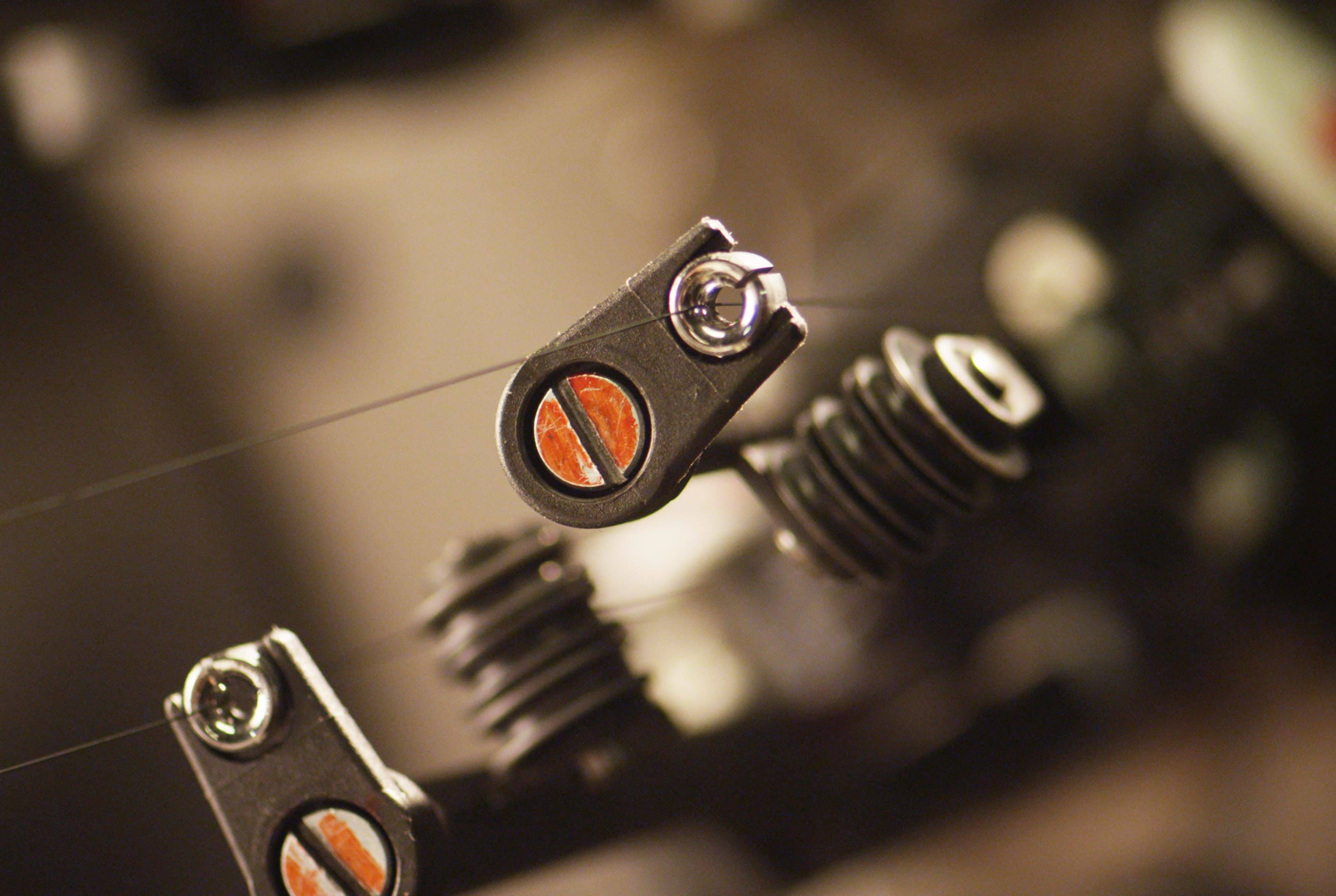

Modernize your braiding operations with Steeger USA’s Braider Control System Upgrade. Designed to enhance efficiency, precision, and reliability, our advanced control systems bring new life to your existing braiding machines. Whether you’re looking to optimize production, reduce downtime, or stay competitive, this upgrade ensures your machines perform at their best.

Why Upgrade Your Braider Control System?

Outdated control systems can limit your production capabilities and lead to inefficiencies. By upgrading to Steeger USA’s advanced control systems, you’ll gain:

- Improved Machine Performance: Achieve precise control and consistent results with upgraded HMI and PLC systems.

- Enhanced Efficiency: Reduce setup times and minimize downtime with user-friendly interfaces and automation features.

- Future-Proof Technology: Ensure compatibility with modern materials and processes.

- Better Data Insights: Monitor and optimize operations with real-time analytics and advanced diagnostics.

Key Features of the Braider Control System Upgrade

- Advanced HMI (Human-Machine Interface):

- Intuitive touchscreen controls for easy programming and monitoring.

- Streamlined navigation for faster setup and adjustments.

- State-of-the-Art PLC (Programmable Logic Controller):

- Enhanced processing power for improved precision.

- Reliable performance to handle complex braiding tasks.

- Seamless Integration:

- Compatible with existing Steeger USA braiders and other machine brands.

- Minimal disruption to your operations during installation.

- Customizable Solutions:

- Tailored upgrades to meet your specific production needs.

Benefits of the Upgrade

- Maximized Productivity: Keep your machines running efficiently with advanced controls.

- Reduced Maintenance Costs: Upgrade outdated components to minimize failures and costly repairs.

- Consistent Quality: Ensure every braid meets the highest standards with precise control settings.

- Eco-Friendly Operation: Reduce energy consumption with optimized control systems.

Installation takes 2 days and is performed on-site at the customers facility. Contact us to schedule your upgrade appointment.

Package Details

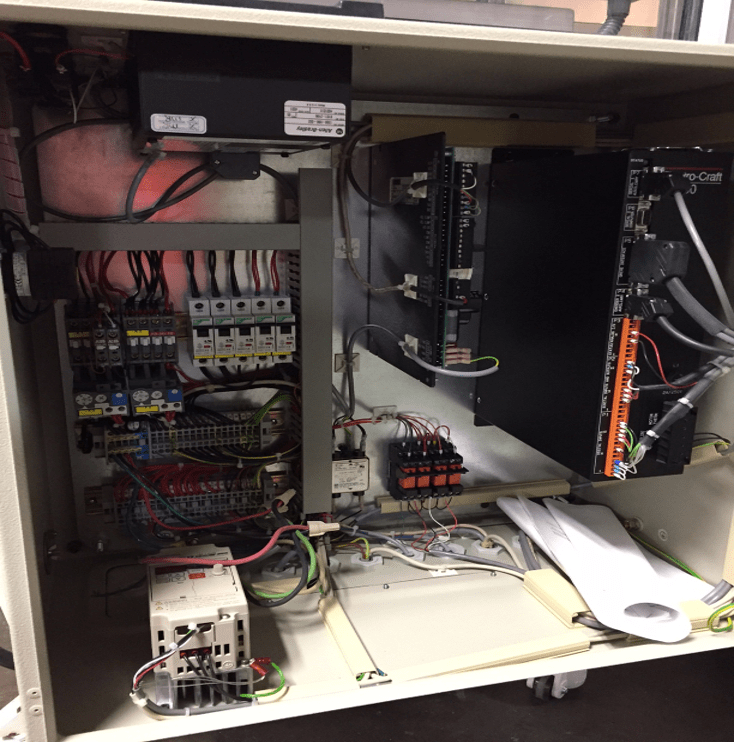

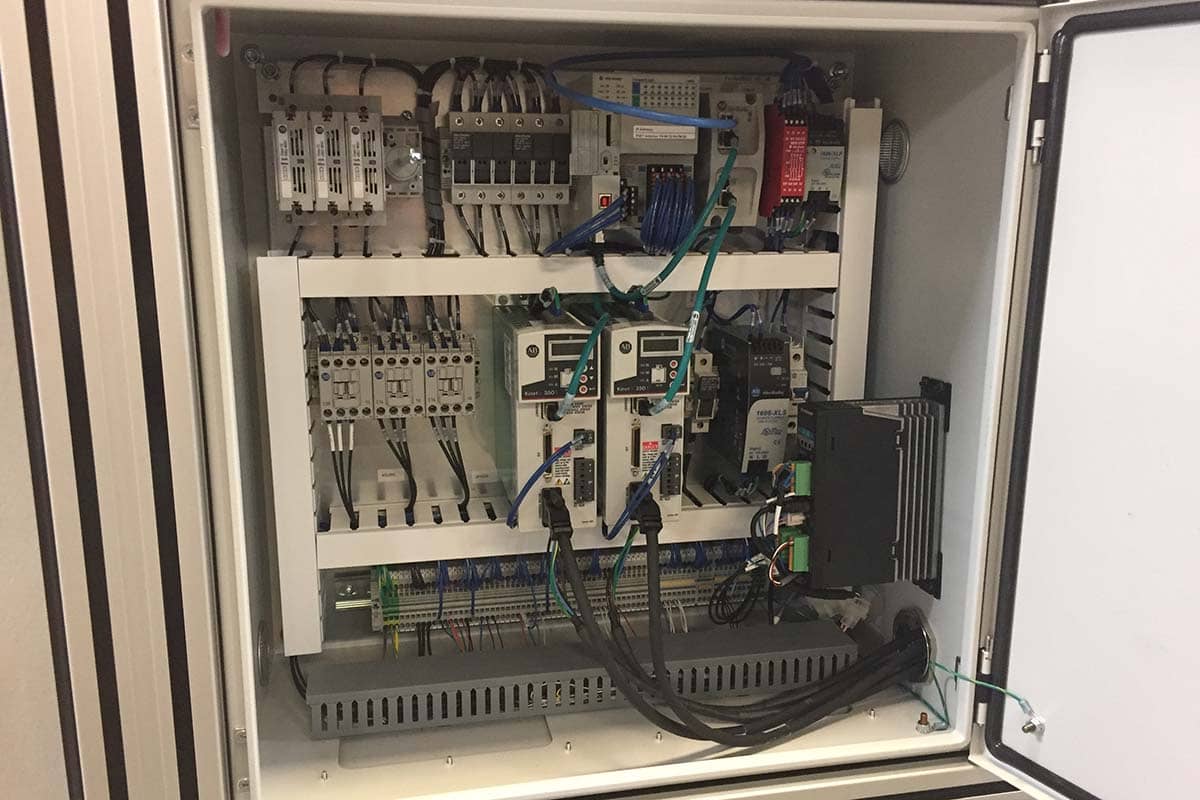

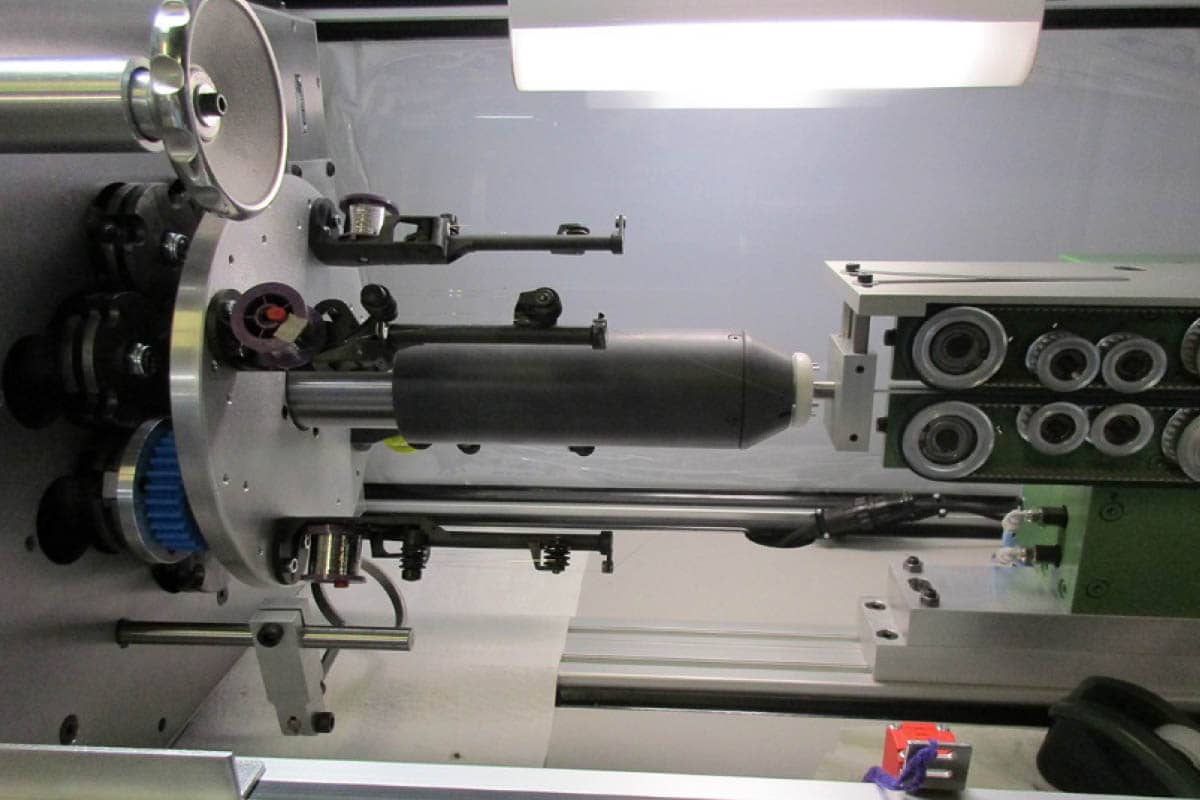

Retrofit IMC package is designed as a replacement for the older IQ550 control system on Steeger USA machines built prior to 2007 (spare parts no longer manufactured for the IQ550). The new system is a “Plug & Play” design that will allow for the old control panel to be pulled out and replaced with new IMC system.

Features:

- Ability to use either Allen Bradley or B&R system components

- Table drive updated from AC motor to servo motor for better control of table speeds and positioning, increased max rpm of 400 or 800 ppm, and larger ppi range of 0 – 600

- HMI is 6” color touch screen

- Software capabilities include:

- Control of operator levels

- Stores up to 25 product recipes

- Capable of 25 variable braiding segments

- Capable of transitional segments

- Hardware expandable for Ethernet capabilities and additional I/O, for example adding data collection.

- Allows for ease of software customization on specific applications