Carrier Exchange Program

Maintain Consistent PPI and Reduce Wire Breaks with Steeger USA’s Carrier Exchange Program

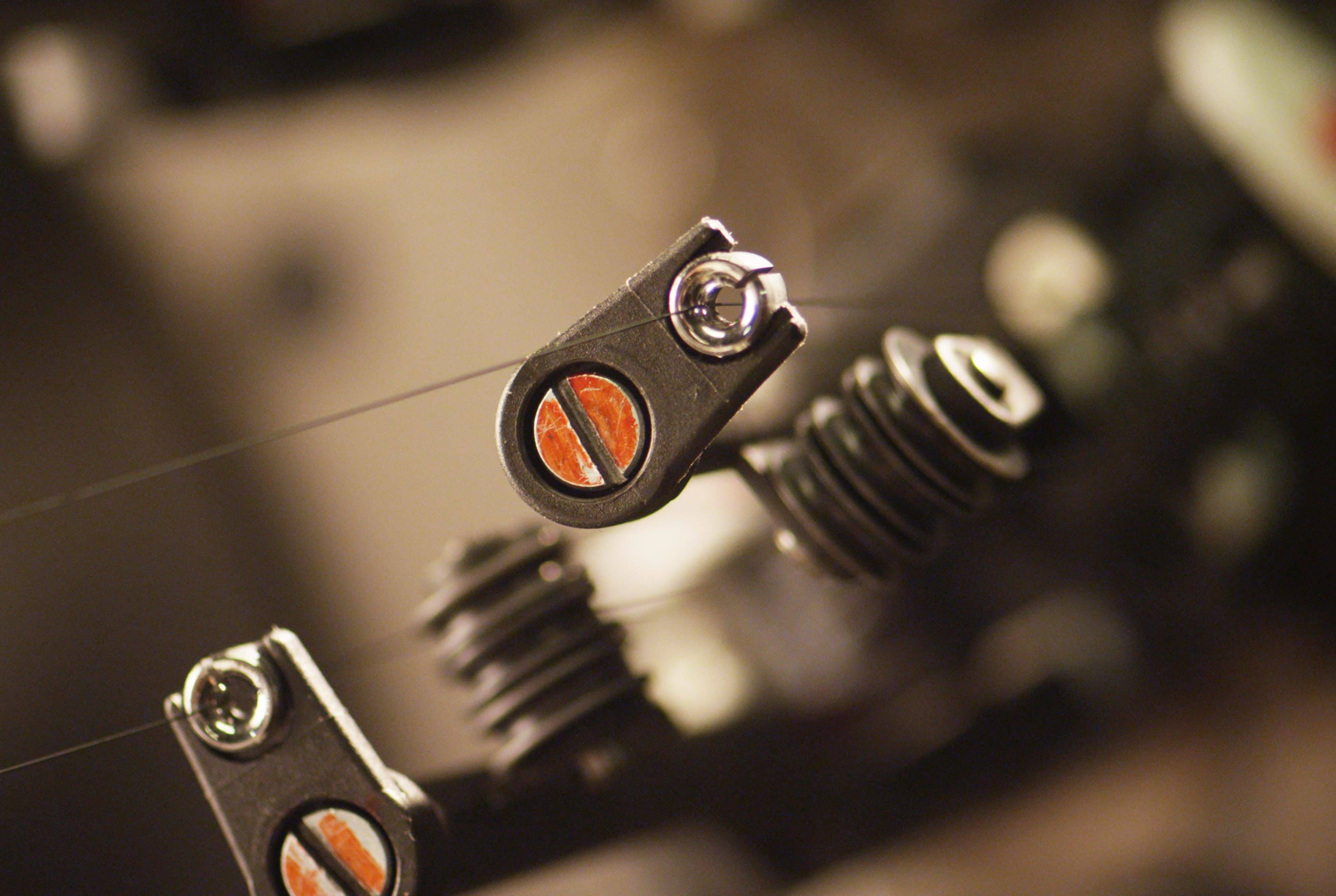

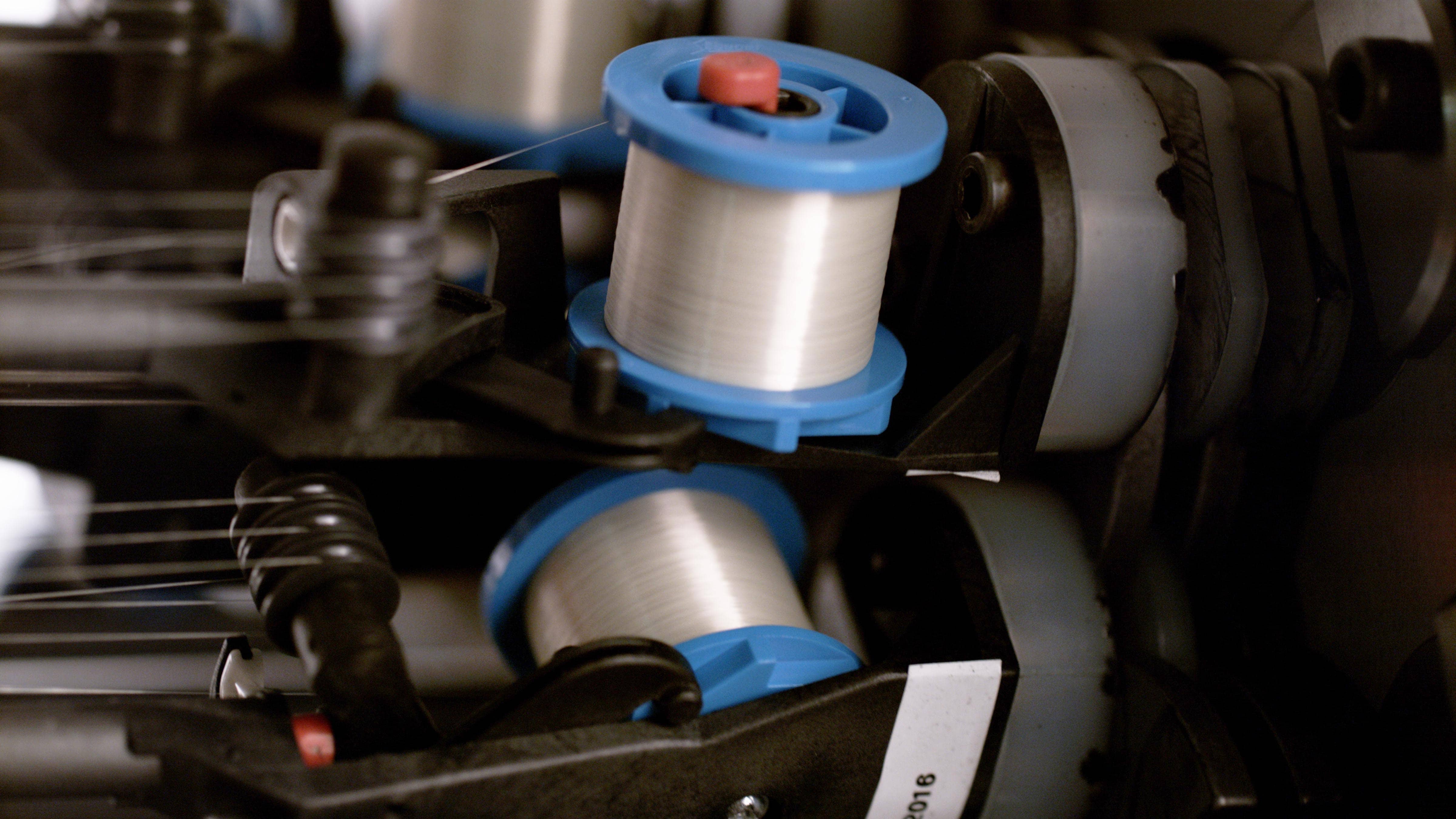

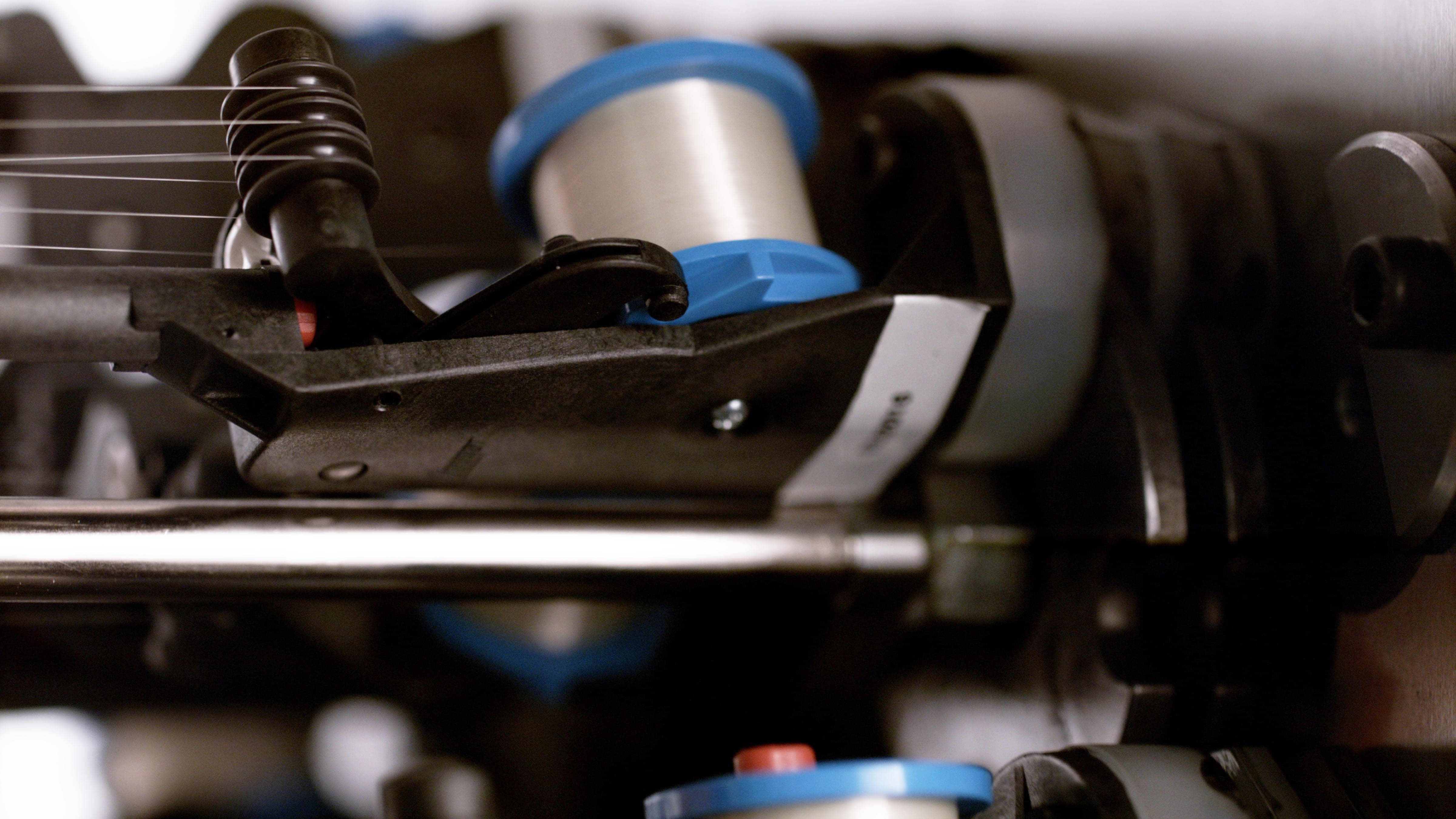

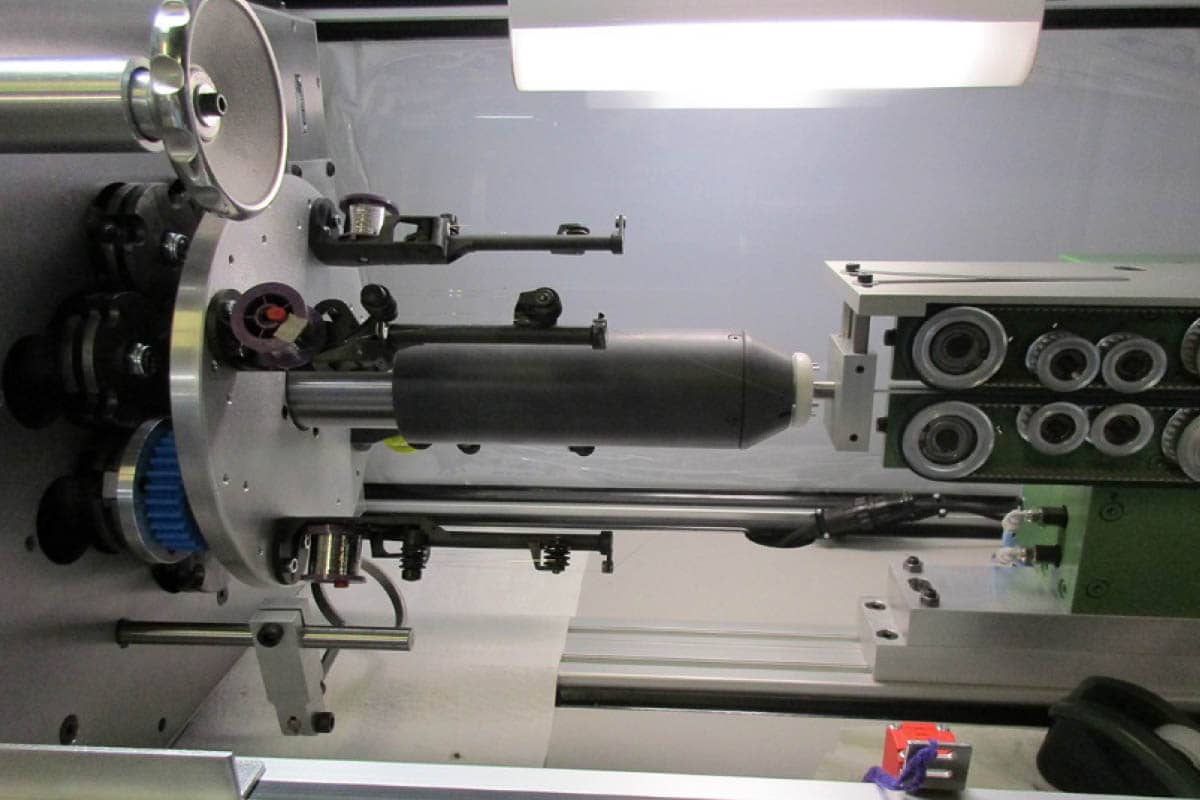

Steeger USA introduces the Carrier Exchange Program, designed to tackle one of the most overlooked aspects of braiding machine maintenance: carrier upkeep. Through extensive field research and testing, we’ve found that regular carrier maintenance on proper cycles significantly improves product quality, maintains consistent picks per inch (PPI), and reduces costly wire breaks.

Why Regular Carrier Maintenance Matters

Carriers are a critical component of braiding machines, directly impacting precision and productivity. Neglected maintenance can result in:

- Inconsistent PPI, leading to uneven braiding.

- Increased wire breaks, causing downtime and material waste.

- Reduced overall machine efficiency.

Our Carrier Exchange Program

Our Carrier Exchange Program simplifies maintenance by outsourcing this essential task to our experts—the very team that builds your machines. This allows your in-house personnel to focus on other priorities while ensuring that your carriers are maintained to the highest standards.

Program Highlights:

- Two Maintenance Options: Choose between Standard or Expedited programs for faster turnaround times than in-house capabilities.

- All New Parts: Carriers are refurbished using all new parts, excluding the body. Damaged bodies are replaced to ensure flawless operation.

- Predictable Pricing: Standard orders include automatic replacement of several bases, with fixed costs for additional replacements agreed upon upfront.

Benefits of the Carrier Exchange Program

- Maintain Consistent PPI: Properly maintained carriers ensure uniform braiding and high-quality products.

- Reduce Wire Breaks: Protect materials and minimize production interruptions with expert carrier refurbishment.

- Increase Productivity: Faster turnaround times and optimized carrier performance mean your machines spend more time running efficiently.

- Time Savings: Free up your maintenance team for other responsibilities while Steeger USA handles the critical carrier maintenance.

Two programs to meet your need

Standard Program

You Dismount and Ship Carriers to Steeger USA for refurbishment We perform maintenance and ship refurbished carriers back. The amount of time between receiving carriers and return shipping will very depending on the number of carriers being refurbished.

Expedited Program

You choose the number of carriers to refurbish and inform Steeger USA. We ship you refurbished carriers from our inventory. When you receive the refurbished carriers remove and replace your old carriers. Send the removed carriers back to Steeger USA for future refurbishments. This program has the added benefit of further reducing downtime.