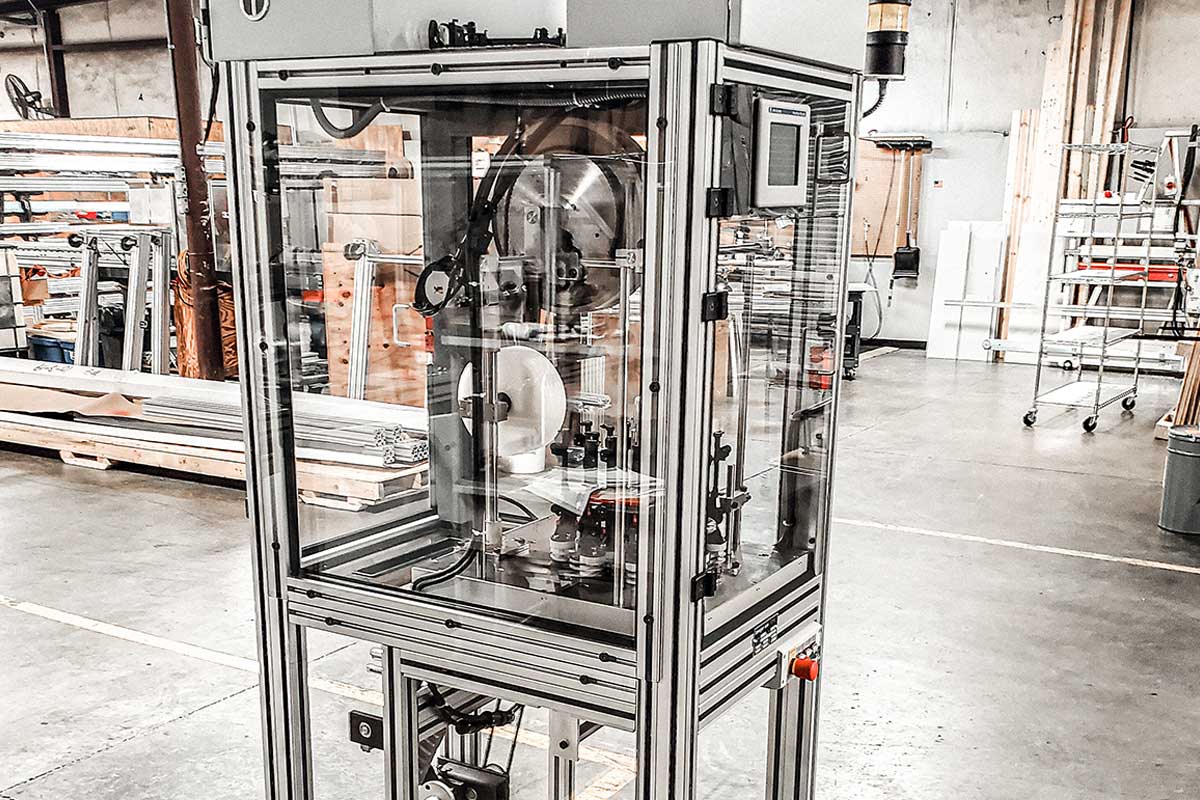

Horizontal Braider Puller Systems

Horizontal Braider Puller for Optimized Production Capabilities

Selecting the right horizontal braider puller is critical to achieving precision and efficiency in your braiding process. Whether you need a dedicated solution for specific product lines or flexibility for diverse applications, we offer two robust puller options for horizontal braiding machines: the Witels Albert Puller and the Versa Puller.

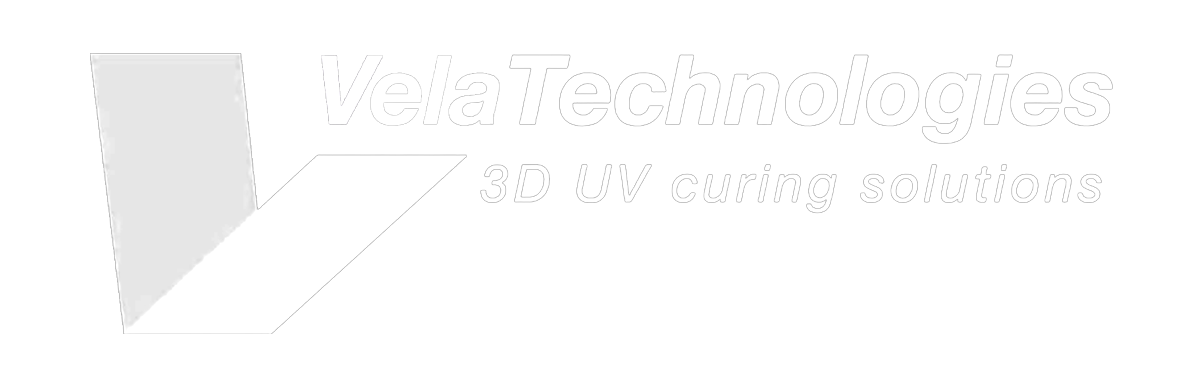

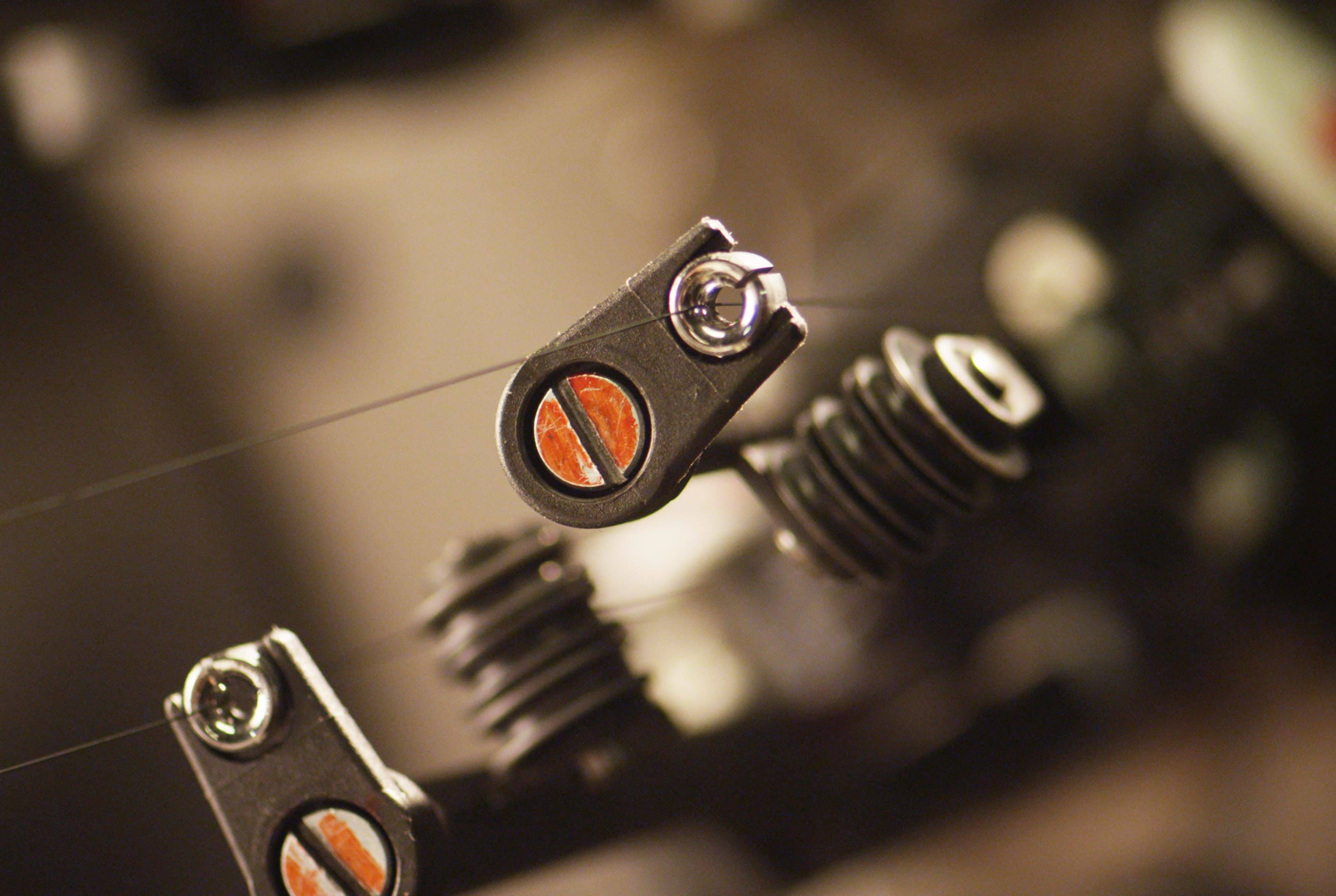

Witels Albert Horizontal Braider Puller

The Witels Albert puller is the standard option for horizontal braiding machines, ideal for dedicated product lines with consistent specifications.

Key Features:

- Jaw Opening: Up to 10mm

- Belt Width: 15.5mm

- Product OD Range: 0-10mm

Considerations:

- Best suited for products with similar ODs or already qualified for this puller.

- When braiding on mandrels larger than 7-8mm, the narrow belts may cause the mandrel to “walk” out of the belts.

- Height Adjustments: The puller height must be adjusted for different mandrel sizes to ensure alignment with the machine head.

The Witels Albert puller is an excellent choice for single-product applications or production lines that require minimal adjustments.

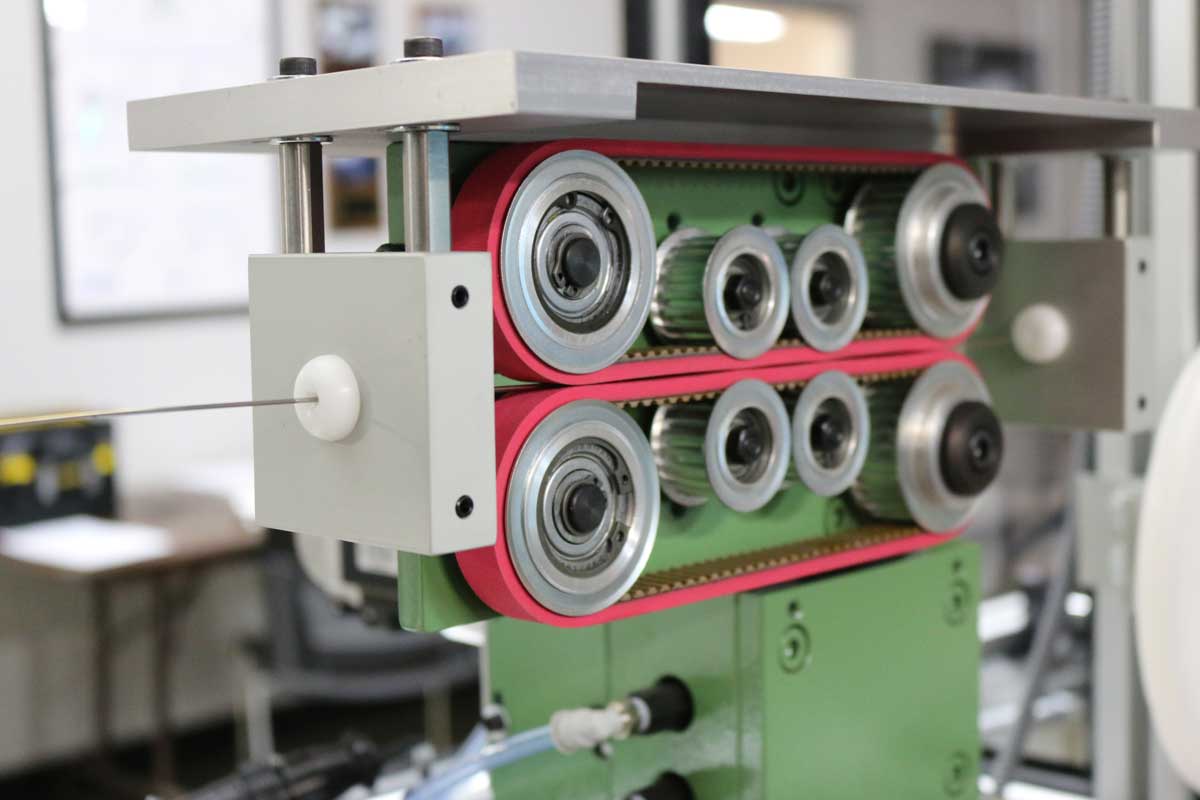

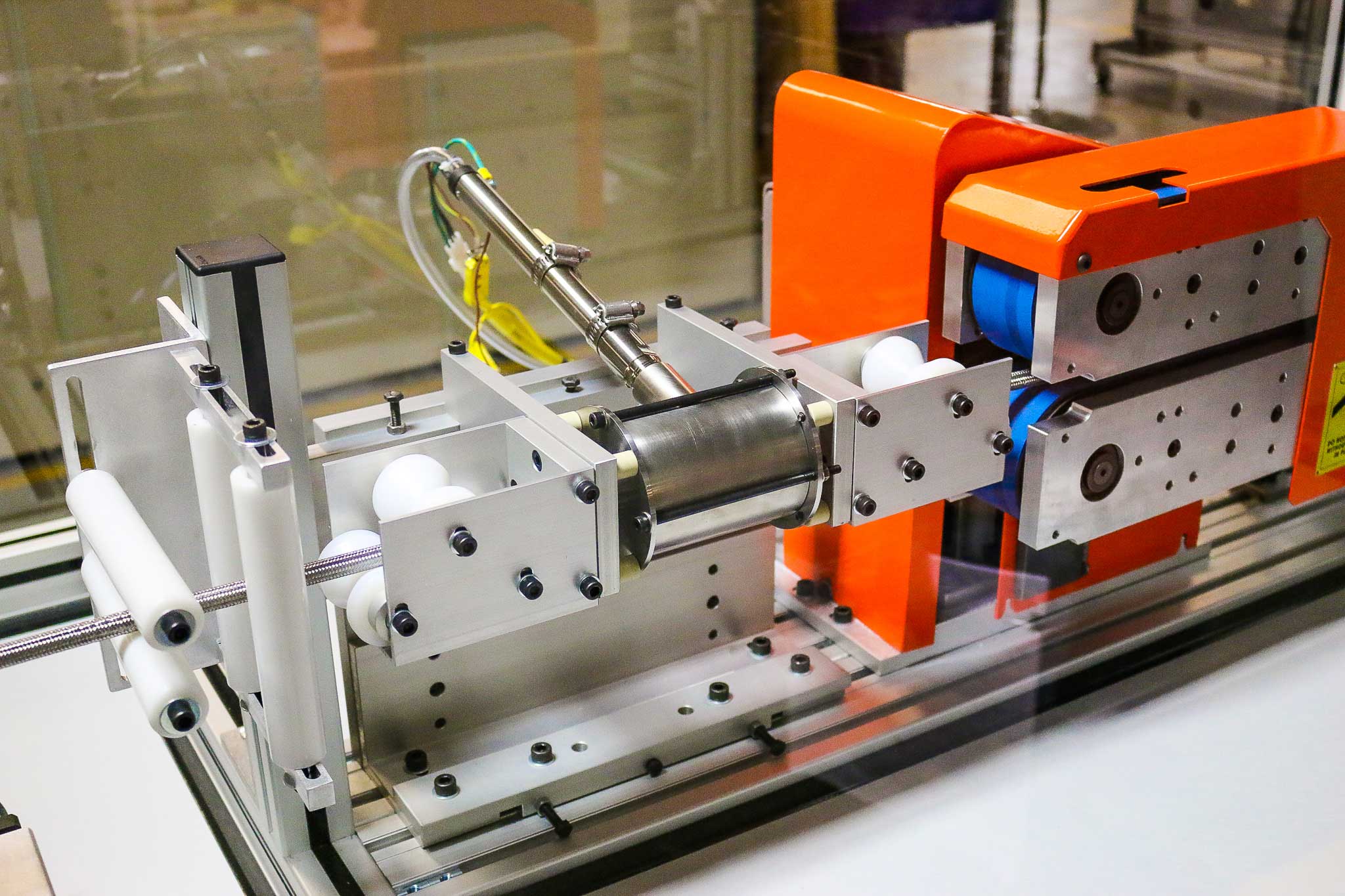

Versa Horizontal Braider Puller

The Versa puller is our premium, upgraded solution for horizontal braiding machines, offering flexibility and enhanced stability.

Key Features:

- Jaw Opening: Up to 50mm

- Belt Width: 50mm

- Product OD Range: 0-50mm

- Self-Centering Jaws: No height adjustments required when swapping product sizes.

Advantages:

- Wider and longer belts minimize mandrel oscillation, ensuring product stability during braiding.

- Ideal for R&D environments or production lines with diverse product sizes, especially for products with ODs larger than 10mm.

- Factory-centered design eliminates the need for additional adjustments, reducing setup time.

The Versa puller is the optimal choice for customers working on varied product sizes, focusing on R&D, or handling larger mandrels.

Choosing the Right Horizontal Braider Puller

- Witels Albert Puller: Best for dedicated product lines with consistent ODs and minimal adjustments.

- Versa Puller: Ideal for diverse applications, R&D, or products requiring enhanced stability and flexibility.

Product Features

Product Range (OD):

Witels: 0 to 10mm

Versa: 0 to 50mm

Band Width:

Witels: 15.5mm

Versa: 50mm

Centerline Adjustment:

Witels: Manual

Versa: Automatic